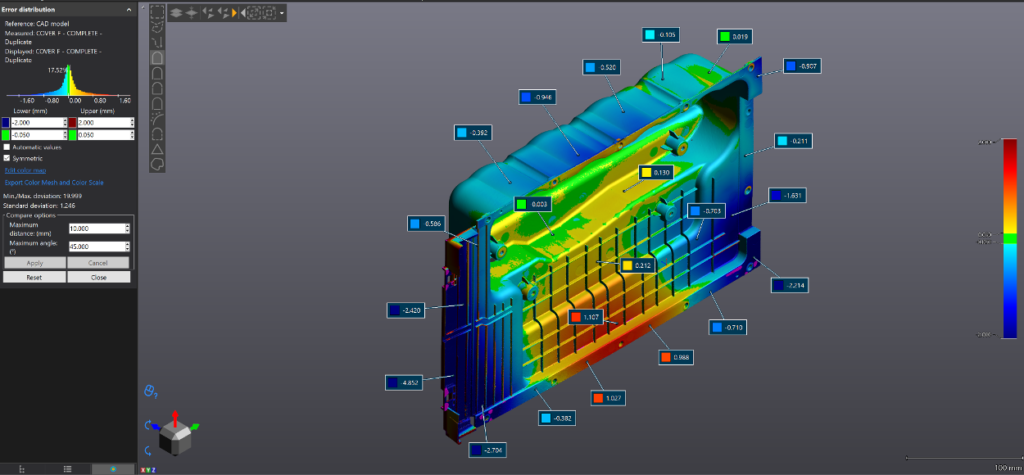

We take pride in our ability to provide ultra-precise 3D laser scanning, paired with expert CAD design experience. Your design, proven.

Contact Us

- 949-345-0611

- 17845 Sky Park Circle Suite E Irvine CA 92614

- contact@usetangent.com

- Monday - Friday 9:00am - 5:00pm