With the rapid advances in technology, 3D laser scanning has become more accessible and affordable than ever before. This powerful tool can be used for a variety of applications, from product design to heritage preservation.

You may be asking, what is 3D laser scanning? It seems that 3D laser scanning technology has taken over the industrial world in a short while because of its unparalleled capabilities. The process is quite simple to initiate. It also takes a fraction of the time to process all kinds of unique geometries with relative ease.

All 3D scanners operate similarly, but the scanning methodology it uses can have a significant impact on the results. The two most common types of 3D scanners available in the market today are 3D laser scanners and structured light or blue light scanners. In this article, we’ll go through the basics of 3D laser scanning and discuss its applications.

If you’re new to 3D laser scanning, this guide will give you a basic overview of how it works and what you need to get started. We’ll also explore some of the different ways you can use 3D scanning in your business or personal projects.

What is 3D Laser Scanning?

3D laser scanning is a non-destructive method of creating digital replicas of physical objects with the help of hardware and software tools. The technology uses a series of laser to cover each surface and translate the data in the cartesian plane (x, y, and z coordinates).

This data is then processed by the computer and can be converted into a CAD-friendly format; a proces known as reverse engineering. 3D laser scanners usually deal with over a million data points in a single scan. The process is accurate and can even process the most complex geometries without needing any special considerations.

3D Laser Scanning Services

The 3D laser scanning process is not complicated, and in many cases, it is a cost-effective option as well. However, you’ll need to invest a considerable amount in an industrial scanner, associated software, and other resources to get started. Spending so much is not an option for many startups and businesses that occasionally use this technology.

For such businesses that use the technology for reverse engineering, inspection, or any other reason, it is smarter to opt for a 3D scanning service that can perform the scan and deliver a digital file. 3D laser scanning is quite versatile, so you won’t have to make any special preparation.

Read here on 4 Reasons to Hire a 3D Scanning Company

A reliable 3D laser scanning service can carry out the scan and deliver results in a single day. You can even ask for design changes and other services, as most 3D laser scanning services will have a CAD department as well.

For 3D scanning services as well, the business is both scalable and productive due to the versatility of this technology. 3D laser scanning has countless applications across several industries, and a 3D scanning service can cater to all their requirements without making any significant changes. The best 3D scanning companies also have mobile 3D laser scanning services for remote and large jobs.

Applications of 3D Laser Scanning

A distinctive quality of 3D laser scanning is its versatility. Unlike many other methodologies, the scanning process and result quality remain constant irrespective of the application or industry.

This adaptability is among the most prominent reasons why 3D scanning has become so popular across various industries in such a short time.

We have compiled a few industrial areas where 3D laser scanning plays an integral role.

- Manufacturing

- Design Engineering

- Simulation and analysis

- Maintenance and inspection

- Academia and research

- Entertainment and AR/VR

- Archeology and art

- Construction

- Medical applications

The applications of 3D laser scanning go beyond the above-mentioned list. Technology is developing at an unprecedented rate, and a lot of new industries are continually adding 3D scanning to their processes.

Benefits of 3D Laser Scanning

Fast and Accurate

Compared with any other measurement method, 3D laser scanning is both fast and accurate. Not only do you directly get a digital replication of your design in real time, a single 3D scan usually collects numerous data points, which allows it to deliver the results with the utmost precision and consistency. Regular 3D scanners have a tolerance of a few millimeters and it gets further refined if you go for a superior industrial model.

Adaptable and Cost-effective

Another excellent quality of the 3D scanning technology is its adaptability. The same set of equipment and software tools has the capability of catering to the needs of various industries. For prototyping businesses and other similar environments, 3D scanning is also a cost-effective option. Apart from the initial cost of purchasing a scanner and the associated software, you won’t have to spend so much money.

You can even avoid the initial purchase costs by approaching a reliable 3D scanning service.

Delivers Comprehensive Results

Another benefit of using 3D laser scanning, especially for reverse engineering and design applications, is the technology’s ability to conduct detailed scans. Many engineers have had the experience of repeatedly measuring and object again and again to verify extra details. 3D scanning eliminates this issue because the scans register all the data in a single scan.

Suitable for Production

For managers and business owners, continuing operations without breaks is a crucial job. Production breaks can cause unexpected delays, which can cause several other problems down the line. It’s one of the reasons why companies focus so much on preventive maintenance and other best practices to ensure reliability in crucial times. With 3D scanning, quality control 3D scanning can inspect key components without shutting down production and rectify issues proactively.

Safe and Reliable

Building on the last point, 3D scanning also has the potential of improving safety standards in a production environment. In many industrial applications, maintenance of machinery is quite hard due to the harsh conditions, which is risky and unsafe for human operators. For such cases, you can integrate 3D scanning technology in modern robots to carry out the job reliably without endangering human life.

Other 3D Laser Scanning Technologies

3D laser scanning is not the only technology that allows you to recreate objects, assemblies, and terrains digitally. There are multiple other methods of doing this job, but the following are the most popular.

Structured Light 3D Laser Scanning

Both structured light scanners and 3D laser scanners use the same principles to create 3D scans. The only difference is in the wavelength and geometry of the light beam. Both technologies are so similar that some experts do not consider them different. However, the results and acceptable operating conditions of structured light scanners are better than their laser counterparts.

Instead of a laser line or a pointer, structured light scanners cast a fringe pattern on the object and register deformations in it to create a data cloud. Structured light scanners are more accurate and versatile than 3D laser scanners. Blue light scanners can also work in well-lit areas, which is difficult for 3D laser scanners.

Photogrammetry

Photogrammetry is another popular method of creating digital scans that focuses more on realism than accuracy. The technology uses several photographs of an object from all sides and uses their overlap to recreate a digital model.

Photogrammetry is a perfect choice for geological applications and terrain mapping. You can also combine photogrammetry and 3D scanning for large-scale applications.

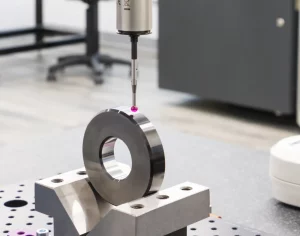

Contact Based Scans (CMM)

When compared to 3D scanning, this method has been around for a while and uses a probing machine called a coordinate measuring machine. In the CMM, a contact probe goes through the entire surface and transfers the data in cartesian coordinates.

The output data of a CMM is quite different than 3D scanners, but you can use bot technologies interchangeably for quality control and inspection. You can’t use CMM for other applications where you need a CAD file or an STL file.

Hiring a Company for 3D Laser Scanning Services

Most businesses prefer to use 3D scanning services because of their expertise and the availability of the best equipment. At Tangent Solutions, we offer the best 3D scanning services in town, and that too at the most competitive prices and in the shortest time.

Our dedicated team of experts has been in the field for more than 15 years and has worked with numerous top brands in several industries. We have all the latest equipment and software for carrying out your 3D laser scans and processing them for further applications. In addition to 3D scanning, we also offer other state-of-the-art services like 3D printing, CAD design, 3D inspection services; to name a few.

Wrapping Up

The world of 3D laserscanning is fascinating, complex, and ever-evolving. It can be used for everything from creating models and prototypes to preserving historical artifacts. If you’re new to the world of 3D scanning, the whole process can seem daunting. That’s why we’ve put together this beginner’s guide to 3D scanning.