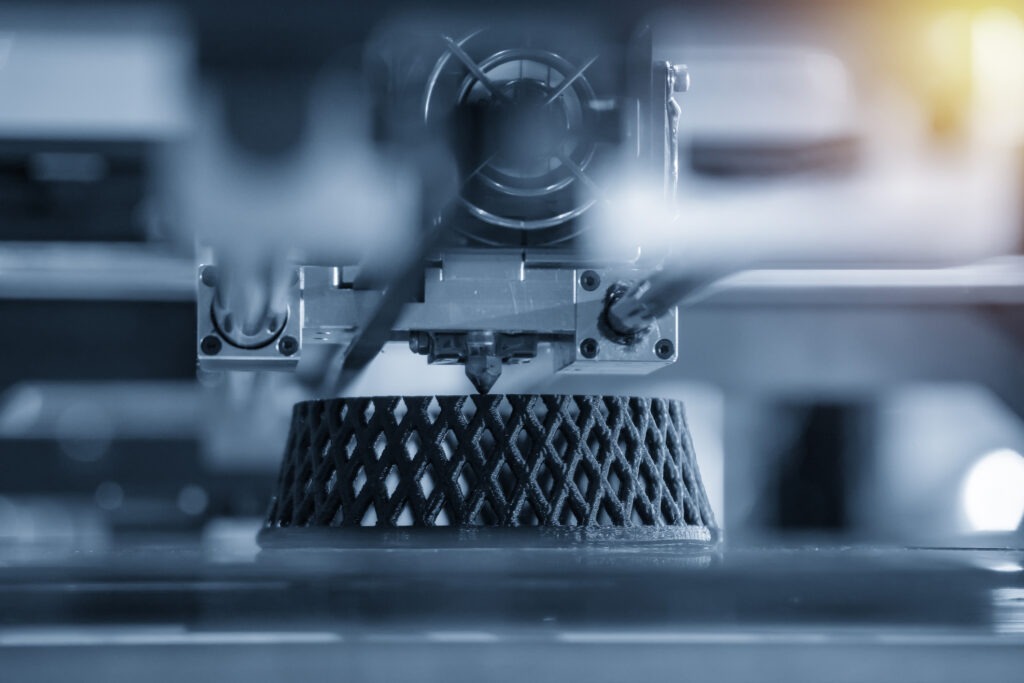

3D laser scanning has accelerated the process of creating digital files. One of the best ways to use this technology is to 3D scan for 3D printing.

How do you use a 3D scan for 3D printing? It seems easy to turn on a laser scanner and create a digital mesh quickly and then hit print, right?

In recent years, the integration of 3D scanning and 3D printing technologies has revolutionized the field of additive manufacturing. While 3D scanning allows for the digital capture of real-world objects, 3D printing enables the physical reproduction of these objects.

However direct translation from 3D scan to 3D printing is not seamless.

In this article, we will explore the challenges and limitations associated with data from a 3D scan for 3D printing, and discuss the solutions to overcome these obstacles. So, let’s dive into the world of 3D scanning for 3D printing and uncover the complexities behind the process.

3D Scan for 3D Printing Challenges

The process of directly 3D printing from 3D scan data presents several challenges and limitations.

Addressing these challenges ensures a successful translation of 3D scan data into printable models, enabling high-quality and accurate 3D printed objects. Educating our clients is a part of why we enjoy working in design engineering.

Below are a few topics that our team will discuss with potential clients that are looking to 3D scan their projects for 3D printing.

Incomplete or Inaccurate Scans

One of the primary challenges when working with 3D scan data is the potential for incomplete or inaccurate scans. Several factors contribute to this issue, including limitations of scanning technology, reflective surfaces, occlusions, and complex geometries.

These factors can result in missing or distorted data, which compromises the quality and integrity of a 3D print file.

When the scan data is not accurate, attempting to 3D print the object directly can lead to flawed results or even printing failures.

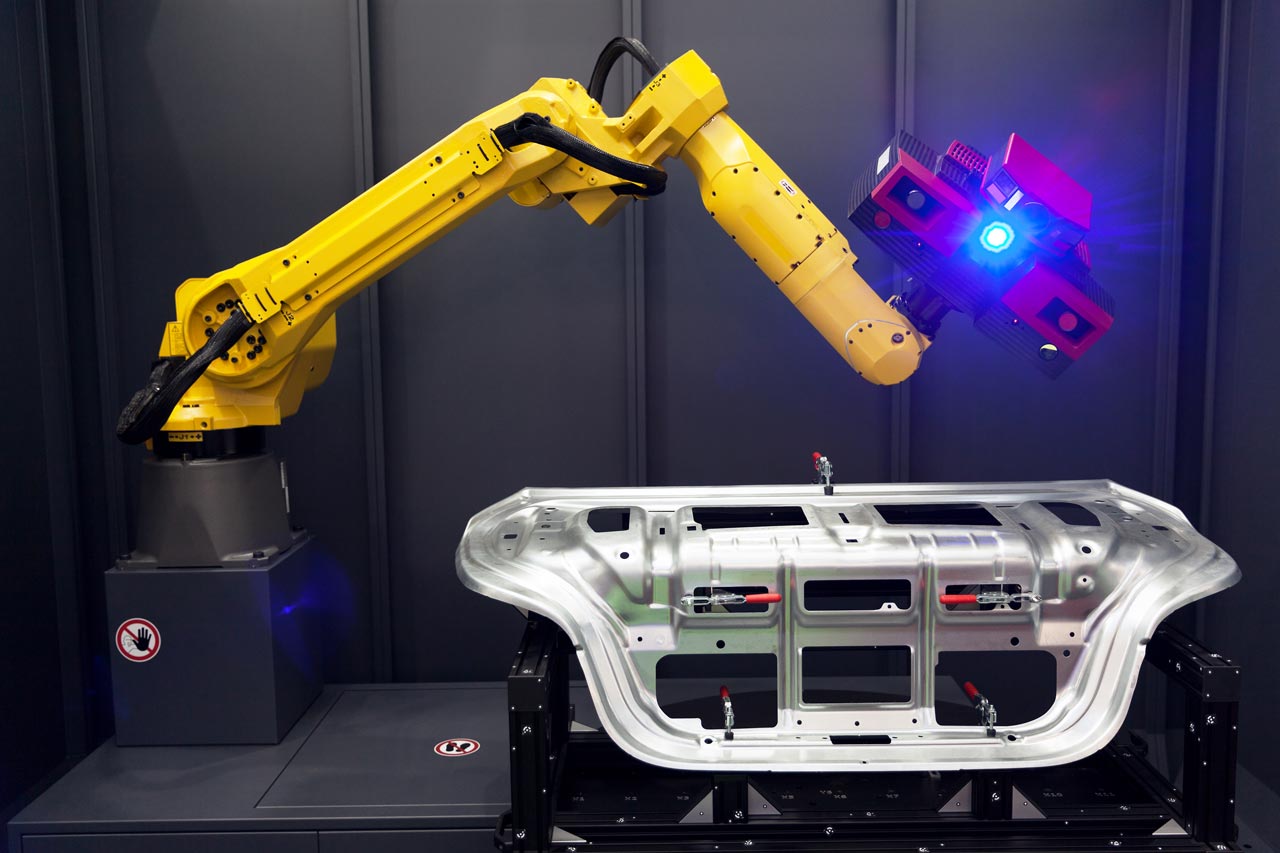

To mitigate this challenge, it is essential to ensure that the scanning process is carried out meticulously. Utilizing advanced scanning techniques, such as using a blue light laser scanner, can improve the accuracy and completeness of the scan data.

It is best to employ the best 3D laser scanning technology available so that data can be collected precisely; up to the thousandth of a millimeter.

Find Out More About Our 3D Scanning Services

Additionally, employing post-processing software to fill in missing areas or enhance the quality of the scan can help generate a more suitable 3D model for 3D printing.

This software is not always available to lower-grade laser scanners.

Our team uses a native post processing software. This process is needed for each 3D laser scanning service conducted. The first export available will be a mesh file, most commonly in STL or OBJ File.

But wait, don’t you just need an STL for 3D printing? Keep reading.

Non-Manifold Geometry

A critical requirement for 3D printing is having a manifold geometry, which means the 3D model must have a completely enclosed and interconnected surface without any holes, gaps, or overlapping elements.

Unfortunately, a 3D scan for 3D printing may result in holes in the files based on the ability to collect data within line of sight.

The line of sight of a 3D laser scanner represents how far the lasers can reach and how much of the project it can “see”. For a proper 3D scan to be collected, the laser scanner cannot be too close or too far away from the object.

This is due to the scanner’s ability to bounce its lasers off small, 6 millimeter targets that are placed on and around the scanning subject. IIf the object being recorded has various holes or tight geometry, there is no area for the lasers to bounce off of.

As mentioned in the previous paragraph, post processing will allow a technician to fill some holes and delete inconsistencies. However, it is not always best to fill holes and it can alter the object’s realistic shape.

Manipulating too much of the data will result in accurate 3D files of the project.

Post-Processing Requirements

Preparing data collected during a 3D scan for 3D printing will require post processing steps.

Post processing involves cleaning up noise, filling gaps or holes in the model, repairing non-manifold geometry, or optimizing the mesh for better printing results.

By utilizing these tools, the scan data can be processed and modified to create a mesh file. This is where many clients feel they will have a successful file.

However, most projects will need additional file creation steps.

3D Scan for 3D Printing: The Next Step

Remember when we discussed line of sight of the 3D scanner? Complex geometries and vital measurements, for example hole dimensions, will not be represented well enough in a mesh file to result in a successful 3D print.

The next step required will be reverse engineering.

What is Reverse Engineering?

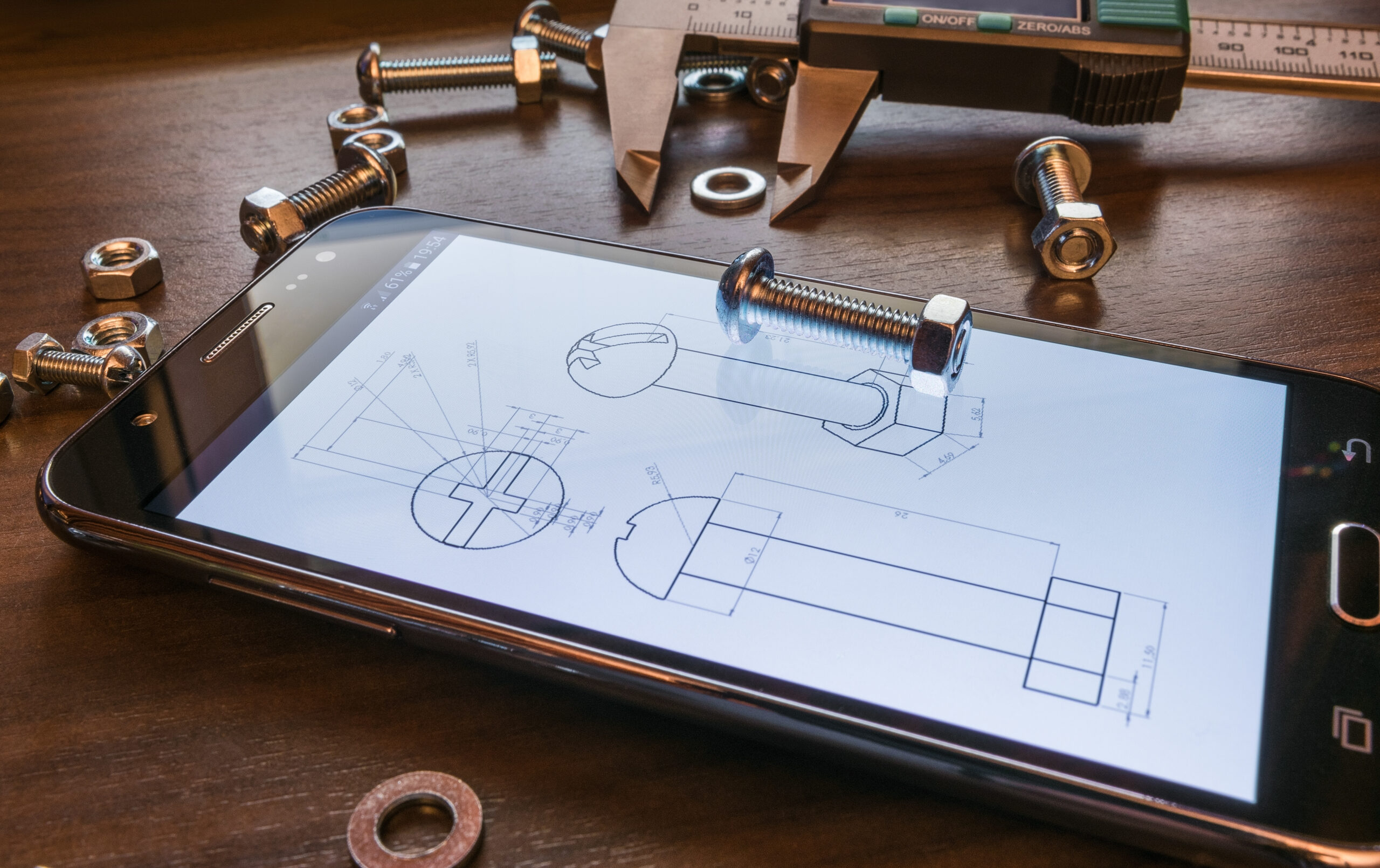

Reverse engineering, in the context of 3D scanning, refers to the process of creating a digital 3D model, commonly into a CAD file.

This process involves using 3D scanning technology to capture the initial shape of the object into the mesh file. From that mesh file, a 3D scan for 3D printing is redrawn, using the mesh as a guide, to create a complete, digital parasolid.

CAD data is essentially “perfect”. All of the holes in the original scan data are filled appropriately to their surrounding areas and dimension is included in the file. Hole shapes will be prope

rly identified and the files are “water tight”.

These files will print successfully. CAD files also have many other uses like manufacturing, quality control verification, and design modifications.

Ready to learn more about reverse engineering? Find out about our reverse engineering services to create ultra-precise 3D CAD models.

3D Scan for 3D Printing Success

Are there ever situations where a file can be scanned directly to a mesh file?

Yes. It simply depends upon your project goals and the detail of your project.

If your project has no complex geometry, holes, and is completely visible for the scanner, then a 3D print file can be created.

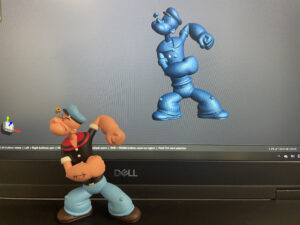

An example of projects we have done for client’s in the past include toy figurines, cookie jars, and show molds. Most of these clients were hobbyists or only looking for a quick representation of their project.

These project goals did not include manufacturing or reproduction.

In such cases, a mesh file can be used directly as long as the quality and accuracy of the mesh meet the requirements of the intended application, additional conversion or post-processing steps are not necessary.

Material and Printability Considerations

Another note when working a 3D scan for 3D printing is material. It’s important to consider the compatibility between the scanned object and the available 3D printing materials and technologies.

Certain objects may contain intricate details or features that are not feasible to reproduce using specific 3D printing methods or materials. Understanding the capabilities and limitations of the chosen 3D printing technology and material is crucial for achieving satisfactory results.

Our team has access to multiple 3D printing materials and processes. We can make recommendations once again, based on your project goals.

By aligning the characteristics of the scanned object with the capabilities of the chosen 3D printing technology and material, successful 3D printing outcomes can be achieved.

Conclusion

While 3D scanning offers an efficient way to capture real-world objects and 3D printing enables their physical reproduction, there are challenges and limitations when directly translating a 3D scan for 3D printing.

Incomplete or inaccurate scans, non-manifold geometry, post-processing requirements, and understanding when reverse engineering will be needed, are factors that must be addressed to ensure successful 3D printing.

Fortunately, advancements in scanning technology and post-processing software have significantly improved the process of preparing 3D scan data for 3D printing.

By employing these tools and techniques, it is possible to overcome the challenges associated with 3D printing from 3D scan data and achieve high-quality, accurate 3D printed objects.

As the fields of 3D scanning and 3D printing continue to evolve, we can anticipate further improvements and innovations that will streamline the process and expand the possibilities of translating 3D scan data into physical objects.

With careful consideration and appropriate solutions, the integration of these technologies will undoubtedly continue to revolutionize the world of manufacturing and design.