Reverse Engineering

Elevate the Functionality

of Your 3D Models

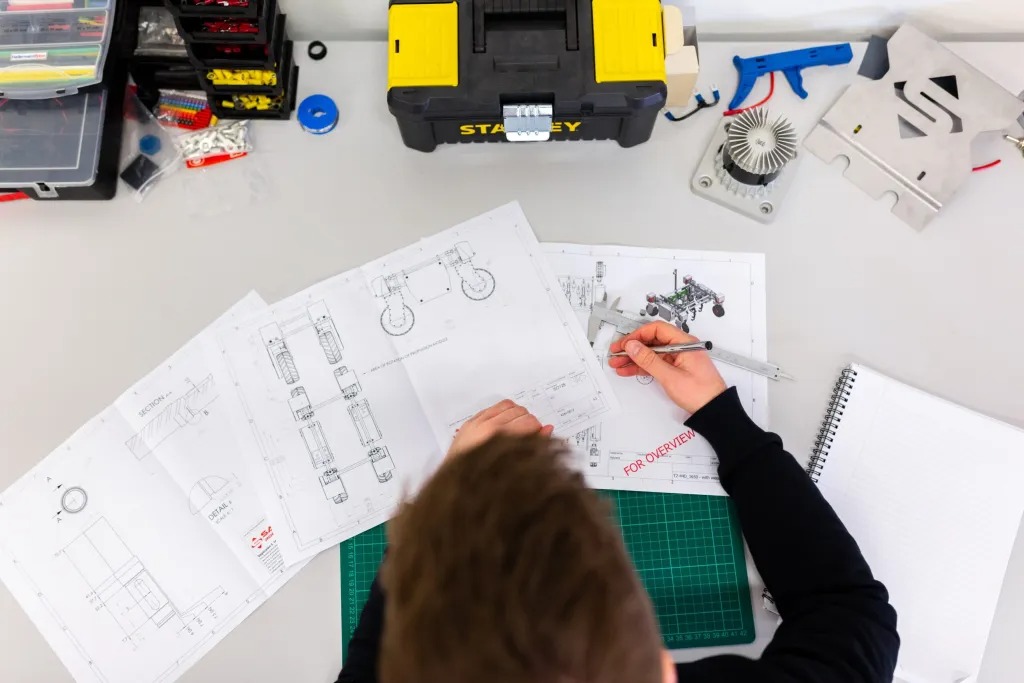

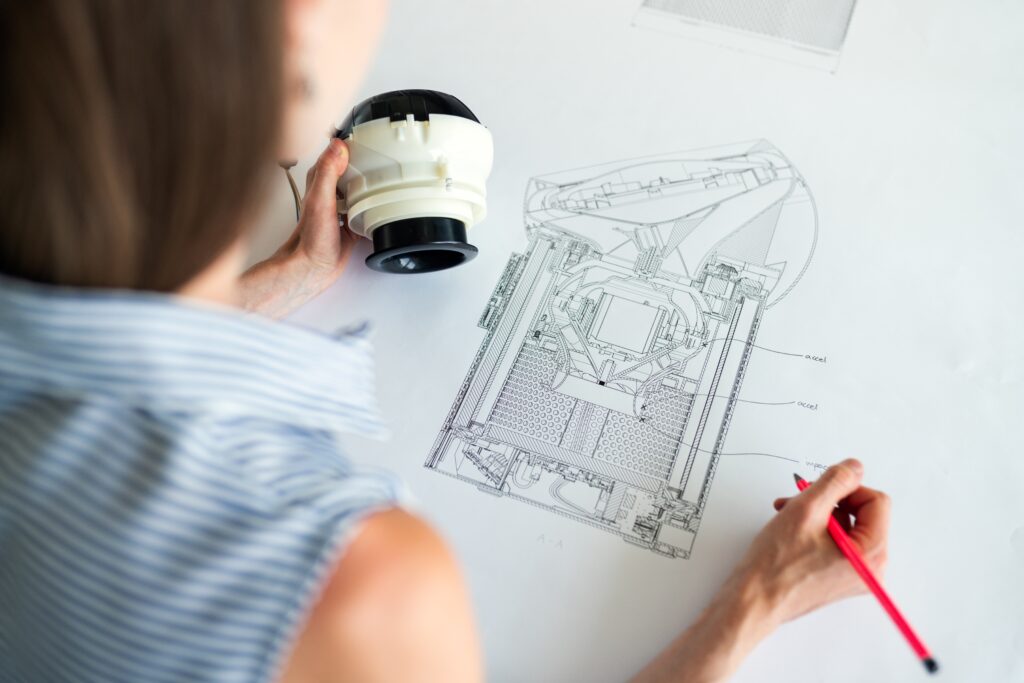

Reverse engineering offers the means to reconstruct a project in cases where existing 3D models are unavailable or have been lost. When combined with 3D scanning services, this process transforms 3D scan data into a fully operational digital model, capable of undergoing dynamic testing, flexion, and rotation.

In the realm of manufacturing, reverse engineering services play a vital role. The accuracy of data obtained through 3D laser scanning proves invaluable in product design when integrated with CAD software, aligning seamlessly with your manufacturing objectives to bring a tangible product concept to life.

Reverse engineering offers an economical solution for businesses seeking to streamline their manufacturing operations.

Reverse Engineering for CAD File Creation

Our team of dedicated CAD engineers specialize in product development and are well-equipped to offer valuable insights and guidance on the most efficient production methods tailored to your project.

Paired with 3D scanning services, initial scan data is created in an ultra-precise mesh file. Our team uses this as a guide to create universal CAD models.

Don’t know what type of file you need? Take a look below.

What Is Reverse Engineering?

In the context of 3D scanning, the process involves creating a digital 3D model of a physical object using data captured by a 3D scanner. Initial scan data is created in a mesh file.

This process allows for design modifications, manufacturing replication, quality control, documentation of historical items, and prototyping. It is valuable in various industries, facilitating the integration of physical objects into digital design and production workflows.

The Accuracy of 3D Laser Scanning for CAD File Creation

Reverse engineering boosts functionality and empowers your team to initiate work on the essential designs you require.

File Creation

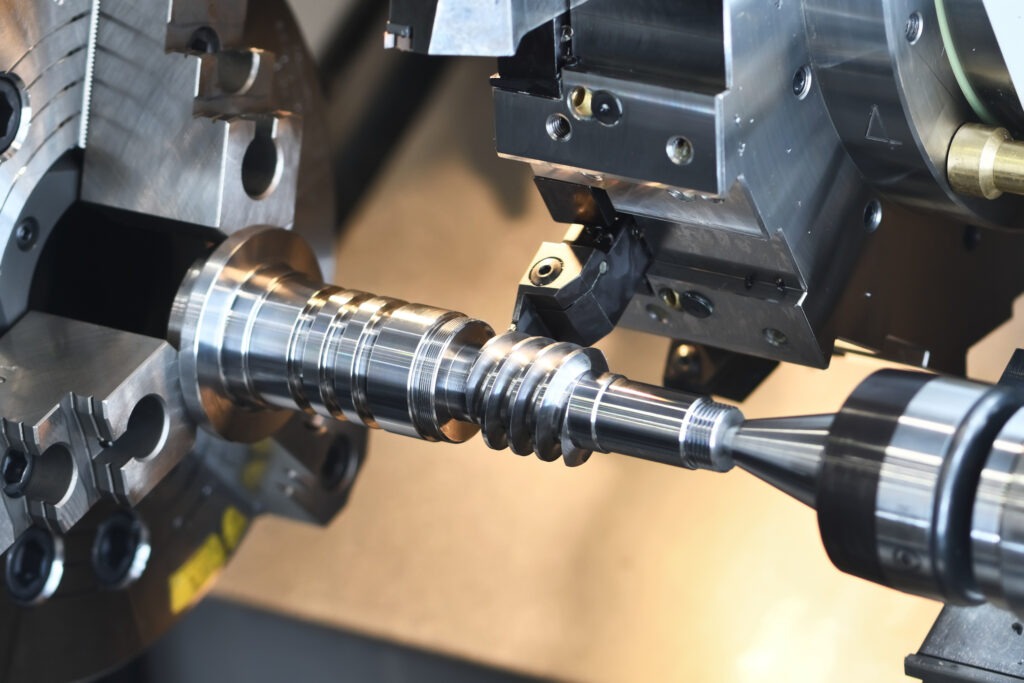

Reverse engineering 3D scan files isolates important project data and provide precise export options such as STEP, IGES, and XT for manufacturing and modification.

Measurements

Reverse engineering services provides high-resolution modeling for precise dimensions and volumetric accuracy. ID, OD, and other vital surface data is represented.

Enhancement

3D scanning technology captures the intricate details and dimensions of an object with high accuracy. This precise data capture serves as the foundation for reverse engineering services.

Compression

Improve performance and optimize storage with our efficient file compression techniques. Avoid the hassle of large file sizes caused by extensive data and resolution.

The Accuracy of 3D Laser Scanning for Reverse Engineering

Tire 3D Scan 37" Tire Rendering

Dirt Bike Rendering

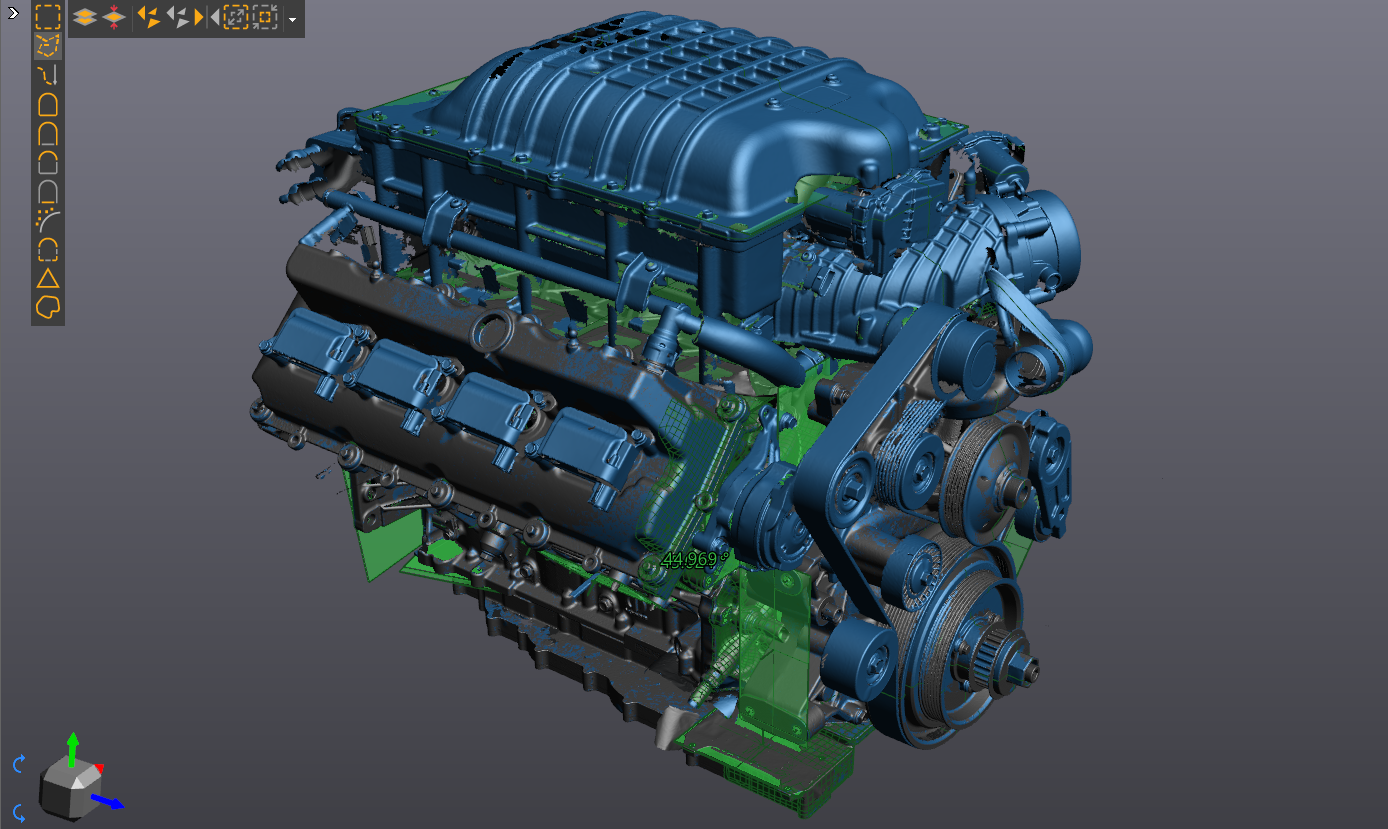

Motor Rendering

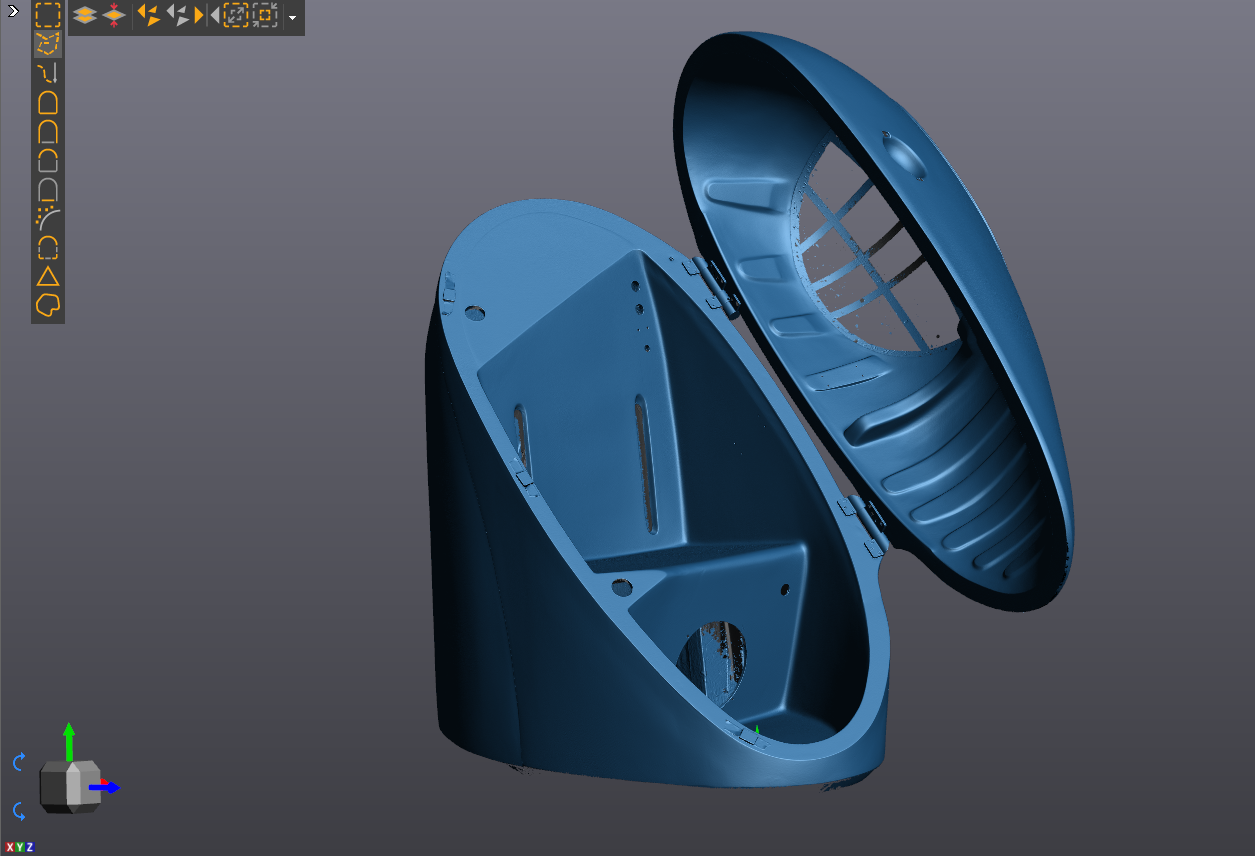

Bod Pod Rendering

UTV Rendering

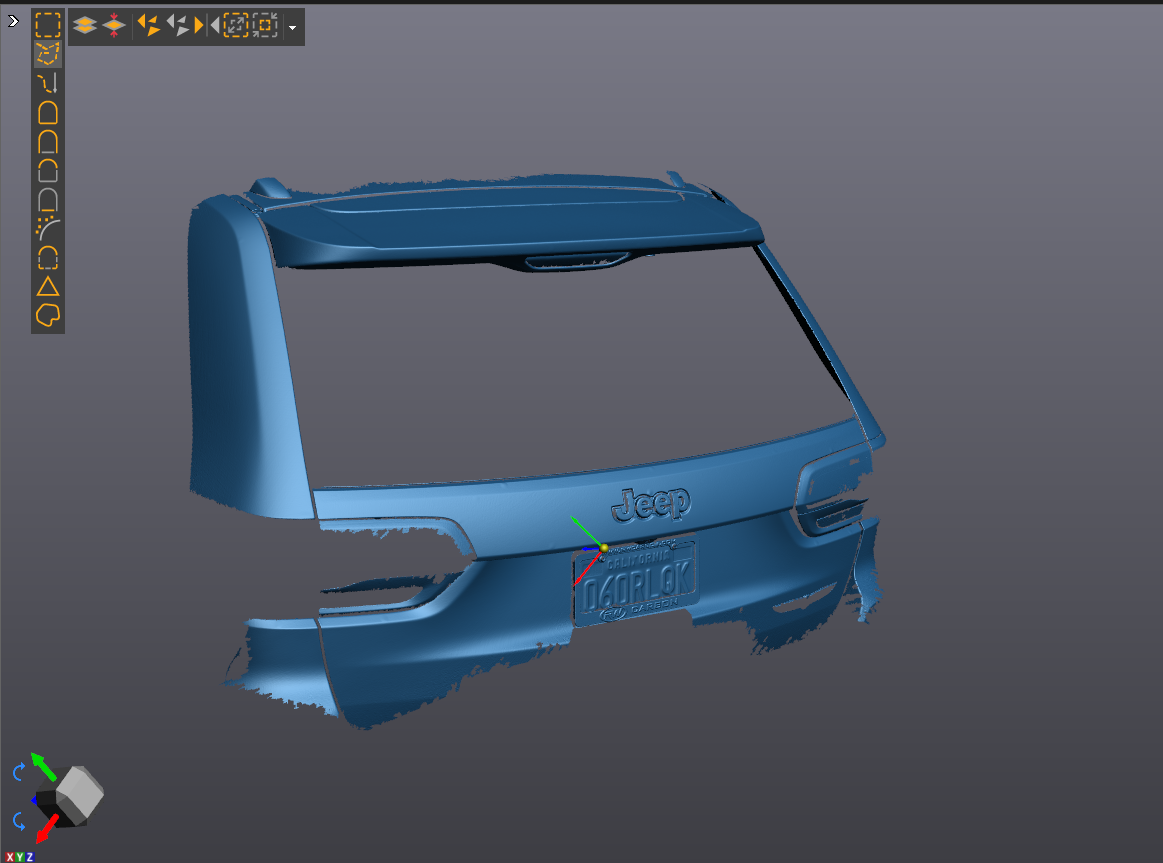

Jeep Rendering

Preparing Your Project for 3D Scanning

When our technicians employ 3D laser scanners to capture your project, blue light lasers meticulously record even the minutest details. Through laser triangulation, scan data is transformed into a mesh, capturing the intricacies based on the distances between various reference points.

Reverse engineering harness this scan data to redraw the part within CAD software. This involves incorporating planes, sketches, and dimensions into the models, resulting in a fully optimized 3D model that can be manipulated. The output is provided in CAD formats such as STEP, IGES, and XT.

benefits of reverse engineering

With the ability to transform your 3D point cloud data into fully functional 3D models, you gain the flexibility to enhance, update, and modify them using CAD tools to assess their performance.

A 3D model serves as an excellent means to showcase a forthcoming product before its market debut. If this is your intended purpose for the scan, then a mesh file is the ideal choice.

Rendering data from 3D scanners may demand time, but the result is a remarkably smooth and highly detailed model, offering unparalleled quality.

FAQ

$115 per hour. This cost covers the creation of 3D CAD files in formats such as STEP, XT, or IGES.

This step is the creation of a 3D model using 3D scan data as a precise reference. The mesh is used as a guide to draw in rendering software with extreme detail aided by the 3D laser scanner.

Most commonly delivered are STEP, IGES, and XT.

Yes, we can deliver the initial export of STL. To work with this mesh file effectively, it’s essential for you or your engineering team to have experience in redrawing scan data.

3D scanning services, quality control, data analysis, CAD design, and product development consulting