3D Scanning Services

State-of-the-Art 3D Product Scanning Services

When accuracy and detail are paramount to your design project, our 3D scanning services provide you with access to the most advanced laser scanning technology, empowering your team with the ultimate tool for digitally rendering physical objects found in the real world.

There is no project too big or too small.

Our 3D design engineers are ready to turn your big ideas into reality by providing a digital representation for more efficient product development. Most projects can be scanned on the day they arrive and promptly returned, without delays in your production process.

Accuracy Up to 0.02mm

3D Laser Scanning

-

Ultra-precise Accuracy

-

In-house in Our Office

-

Same Day Service

What Can You Achieve With

3D scanning Services?

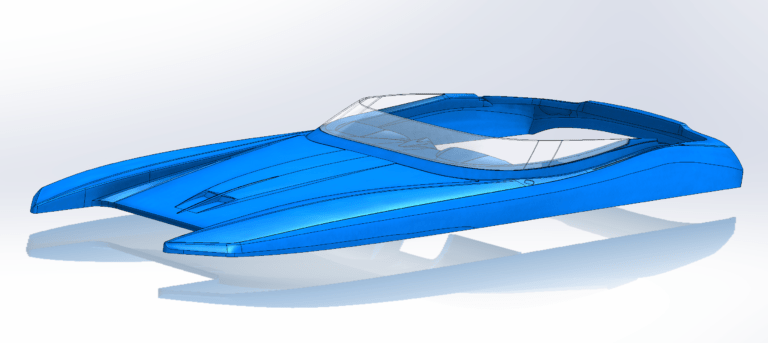

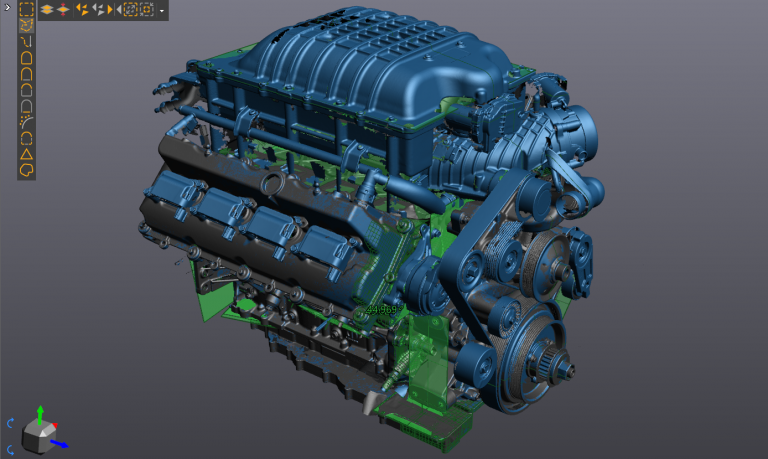

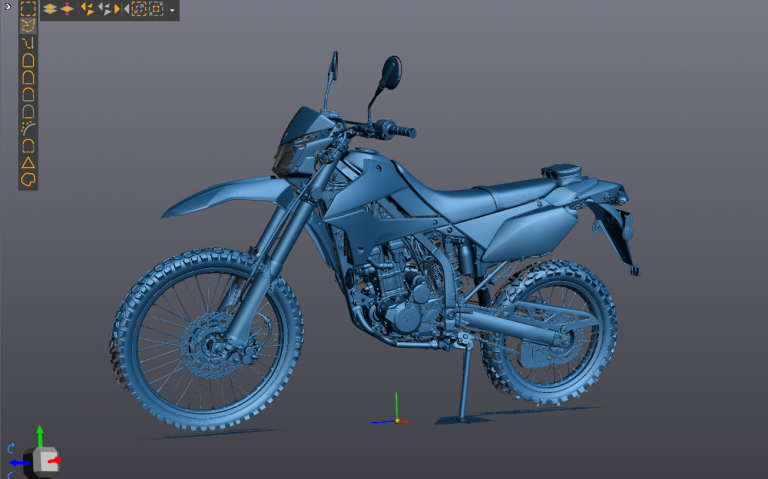

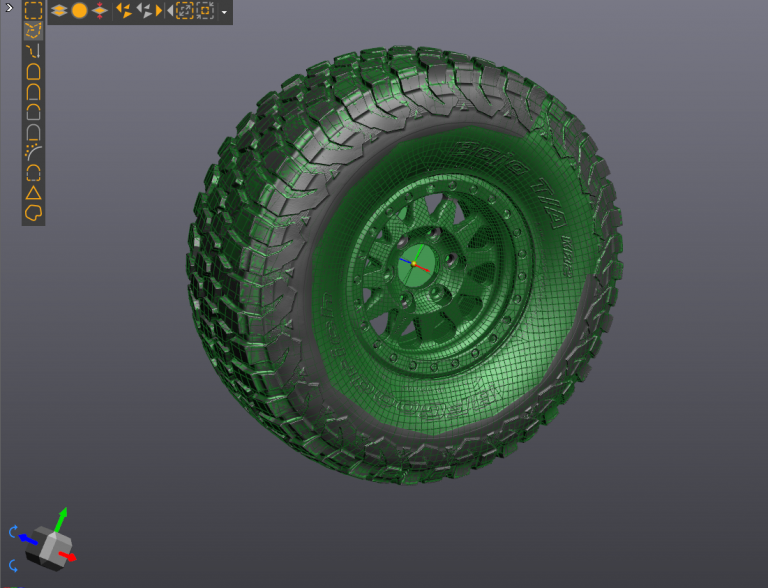

3D scanning is a cutting-edge technology that captures the three-dimensional essence of any physical object, resulting in highly-accurate, digital representations. Its versatility extends to numerous industries, facilitating the attainment of various critical objectives with complex geometries.

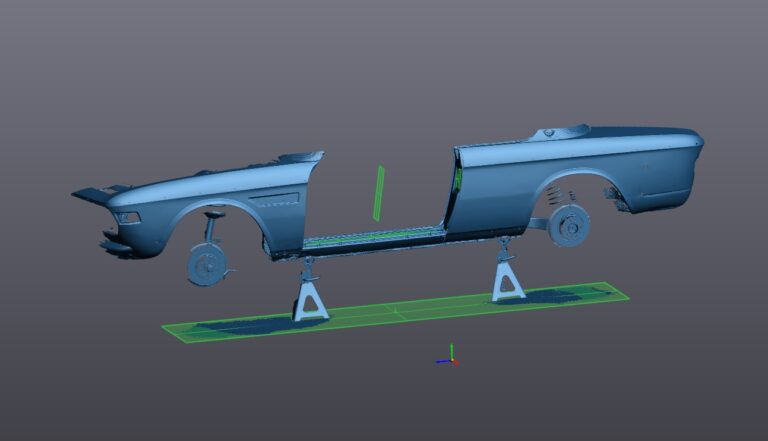

Mesh Files

3D scanning data offers an exceptionally precise and tangible portrayal of real-world objects in a digital medium, simplifying the process of conceptualizing designs prior to the manufacturing phase. Additionally, this data proves invaluable for rapid prototyping and 3D printing, enabling thorough verification of fitment.

Mesh files are commonly delivered in STL and OBJ format.

Digital Assets

3D laser scanning is the fastest way to create a 3D model from its original existence. 3D scanning is invaluable to e-commerace, NFTs, and more.

Scan data can be post processed quickly in order to make a mesh file for 3D printing. STL files are a universal file for 3D printers and can be created within one business day.

File Creation

To see samples of the most common file deliveries, take a look at our sample page.

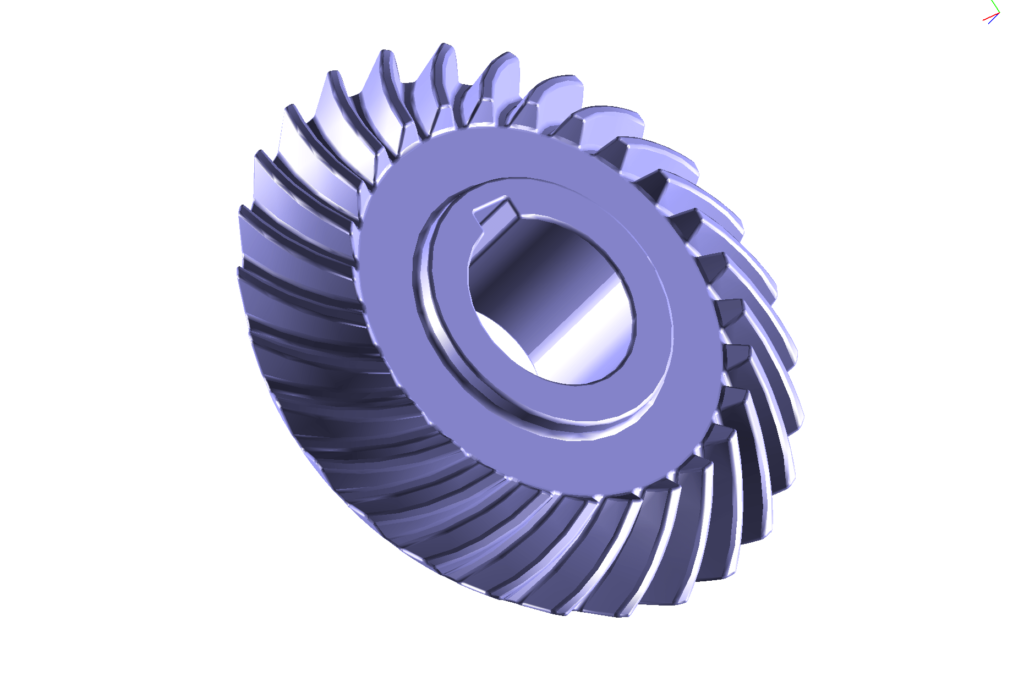

CAD File Creation

We provide all reverse engineering files in universally compatible formats, including STEP, IGES, and XT. These files are effortlessly adaptable for programming across a wide spectrum of manufacturing processes, such as machining, laser cutting, injection molding, forming, and more.

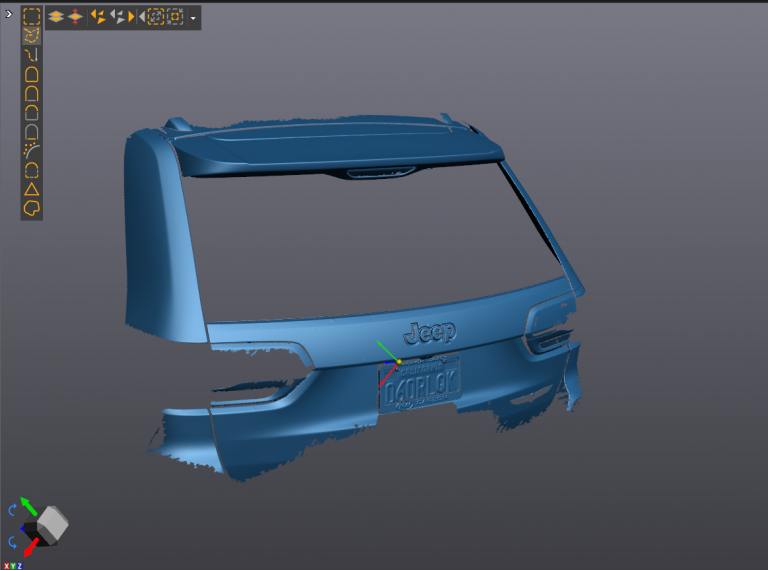

Data Analysis

Scan data will show inconsistencies, variances, and other deviations that can be illustrated in a heat map. This heat map shows differences set to your parameter, tolerances, and variables.

Reverse Engineering

Utilizing 3D laser scanning for reverse engineering applications, provides unmatched accuracy in your CAD files. Scan data can be converted into STEP, IGES, or XT files, to name a few).

Quality Control

Verify quality of a project before taking it to manufacturing. We can compare scan data to your original CAD models to find any discrepancies.

Manufacturing

Tangent Solutions can play a valuable role in your product development goals by offering consultation services that leverage our expertise in manufacturing. Our entire team originates from forming, laser cutting, and machining backgrounds.

Additionally, our team has the capability to locate a suitable manufacturer, domestic and international, while overseeing all logistical aspects of the project.

What Files Do You Need?

The answer depends upon your project goals.

Looking for 3D printing or proof of concept? Mesh files are perfect. If your project includes manufacturing or modifications, you need a CAD file.

Reverse engineering 3D scan data is the most time-consuming but the most vital in order to create a highly-precise, detailed 3D models.

F.A.Q

3D scanning services starts at $155 per hour. This is the rate for in-house scanning, performed in our office by our technicians.

There is a one hour minimum for in-house scanning but most projects we can complete within that timeframe. Most projects can be dropped off in the morning and picked up before end of day.

3D laser scanning works by preparing laser triangulation. The object to be scanned is prepared with reflective targets that the scanner records by bouncing lasers on and back to the scanner. Between these targets, a digital mesh is recorded, identifying different surfaces, dimensions, and features. This scan data digitally records all that it sees into a 3D model.

Immediate data from 3D laser scanning is prepared in the native software. All scan data must be post processed with the quickest files being prepared as STL and OBJ files. Scan data can be reverse engineered to create CAD files.

Tangent Solutions main office is located in Irvine, in the heart of Orange County, Southern California. Our services are available to all domestic and international clients as our technology is completely mobile.

Mobile 3D scanning services, data analysis, product development consulting, CAD design services, and reverse engineering.

Rely On The Best In 3D Scanning Services

Superior 3D Scanning Services, CAD Design, and Product Consulting.