3D Scanning Company

Precision 3D Laser Scanning

& Reverse Engineering

Faster, More Accurate, On-Demand.

Trusted by Aerospace, Manufacturing, and Product Development Leaders

for CAD Modeling and data inspection

Experience Accuracy and Innovation with Tangent Solutions

Who is Tangent Solutions

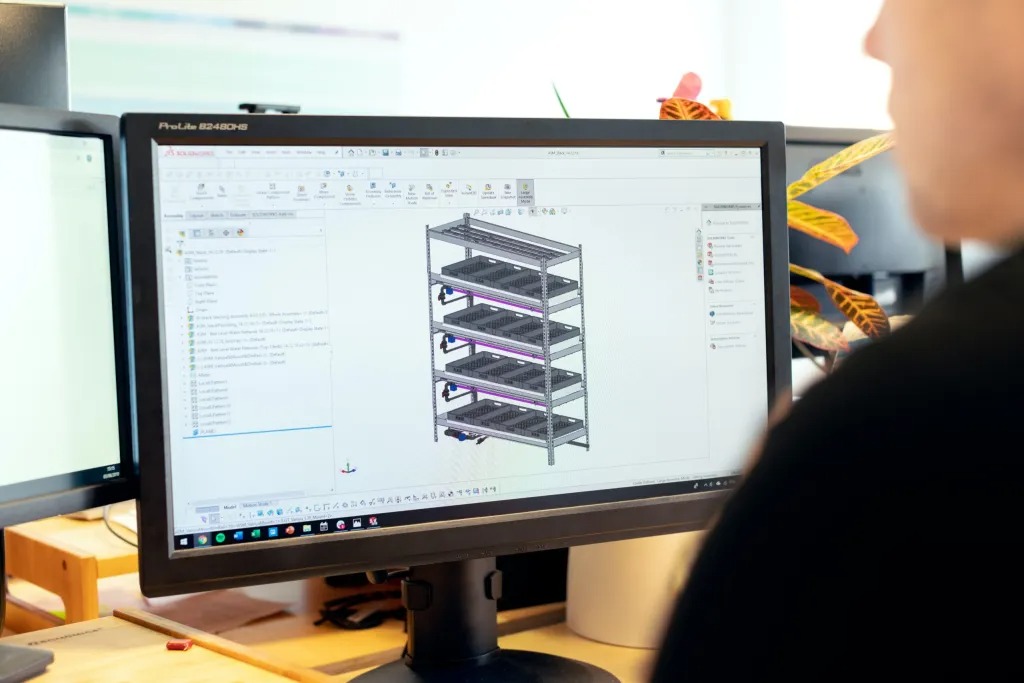

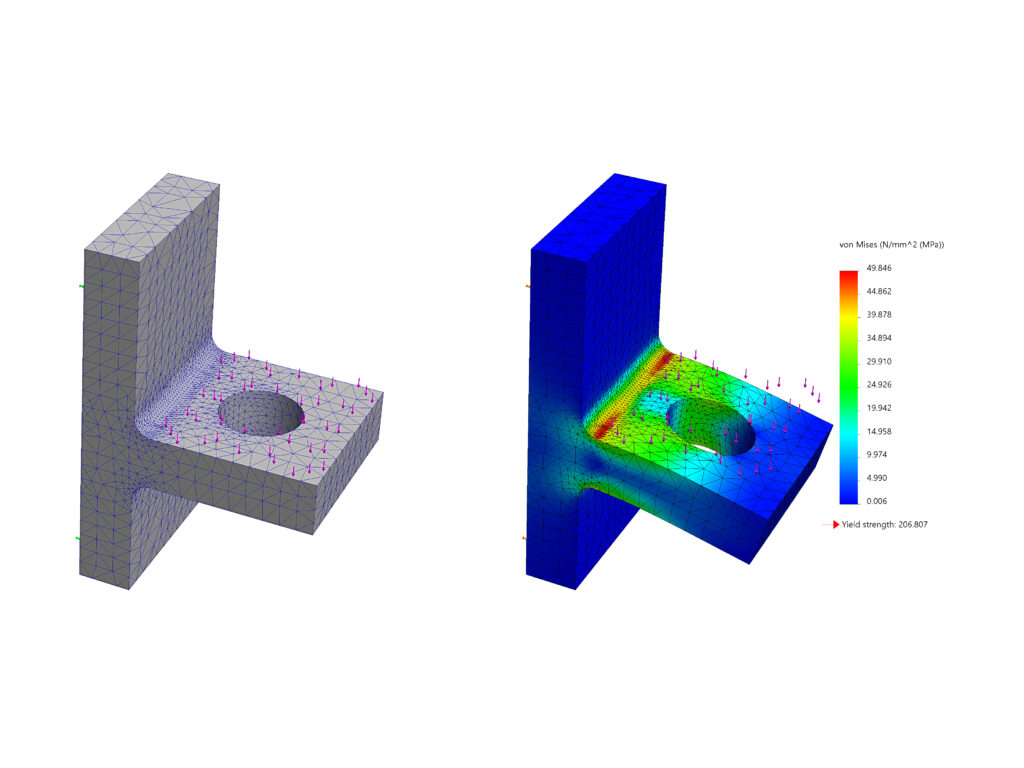

With expertise in product development, CAD design, and complex engineering challenges, we provide tailored solutions to turn your vision into reality—offering unmatched precision and dedicated support.

As a leading reverse engineering and 3D scanning company, Tangent Solutions harnesses cutting-edge technology to create ultra-precise designs, ensuring your products are both efficient and highly profitable. Tangent Solutions is a premier 3D scanning company, offering precise and reliable 3D scanning solutions for various industries. Whether in aerospace, automotive, or mining, our advanced 3D laser scanning company techniques deliver highly detailed, non-destructive scans. From intricate parts to complex assemblies, we transform physical objects into digital CAD models for superior accuracy and performance insights.

With a dedicated team of engineers and cutting-edge tools, Tangent Solutions holds a solid reputation as a trusted CAD design company. Our services streamline product development, enhance efficiency, and ensure precision down to 0.02mm accuracy. We cater to businesses needing actionable data for manufacturing, quality control, or reverse engineering. Partner with us for industry-leading 3D scanning solutions designed to elevate your project’s success. Our commitment to quality and customer satisfaction ensures we exceed your expectations at every step.

Tangent Solutions is A Comprehensive, Design Engineering Company

Services Provided

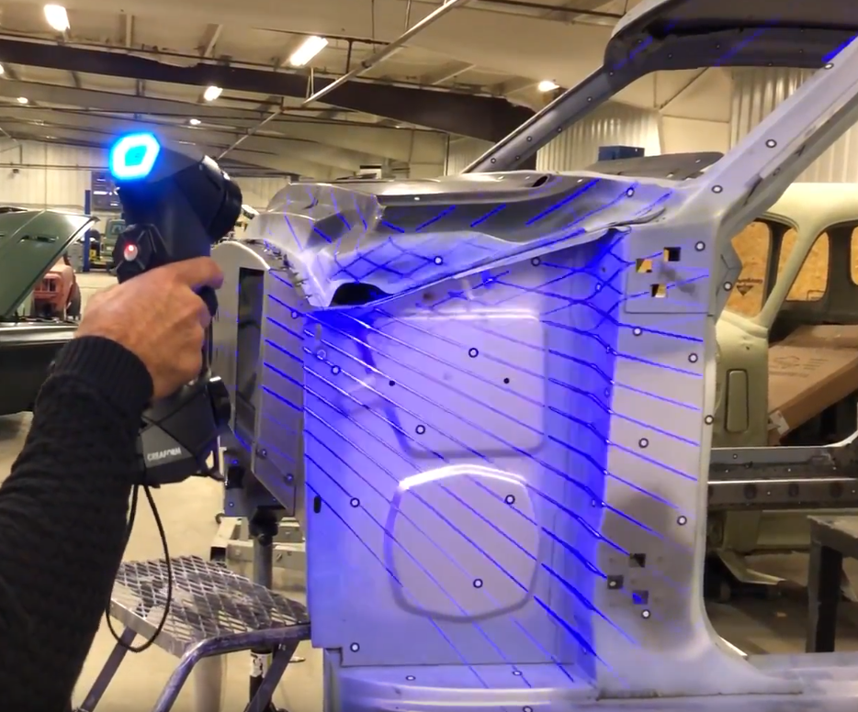

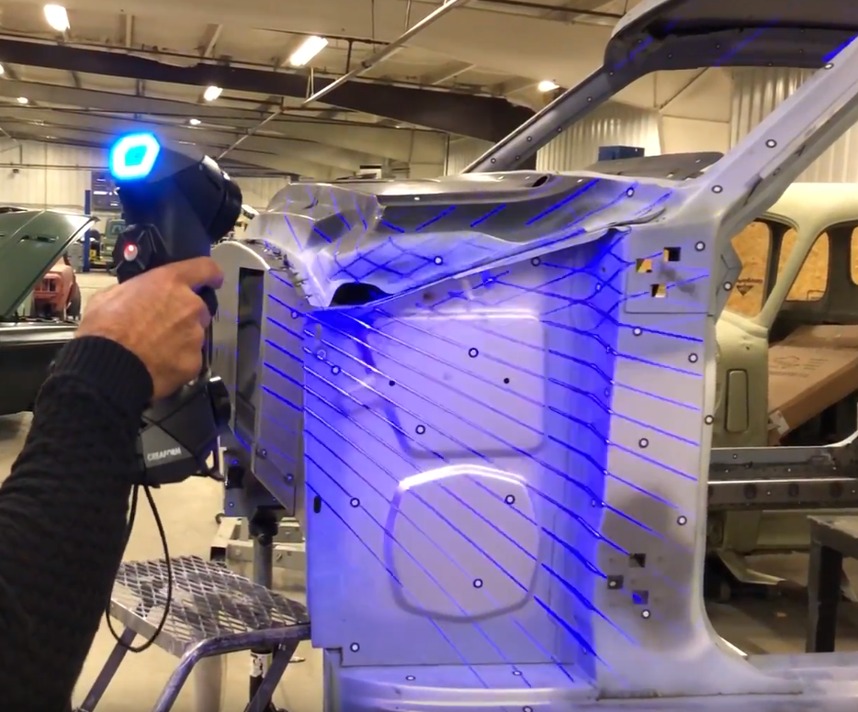

The 3D Scanning Process

Project Quote

Share project goals and photos. An accurate quote is itemized to include scanning, processing, and file creation.

3D Scanning

3D scanning services delivers ultra-fast, reliable accuracy with up to 0.02mm resolution for projects of any size.

Reverse Engineering

Scan data is cleaned up, orientated into mesh format; STL or OBJ. Data can then be reverse engineered to STEP, IGES, and XT.

File Delivery

Files are provided in a universal CAD format for your review, with optional 2D prints for manufacturing.

Why Choose Tangents Solutions

Fast turn-around

Same Day Service

Expert Technicans

Universal File Delivery

In-House Teams

Our Expertise is Trusted By Our Clients

What Clients Say About Our Services

Customer Reviews

Recent Case Studies