3D Scanner Reverse Engineering

What Is Reverse Engineering?

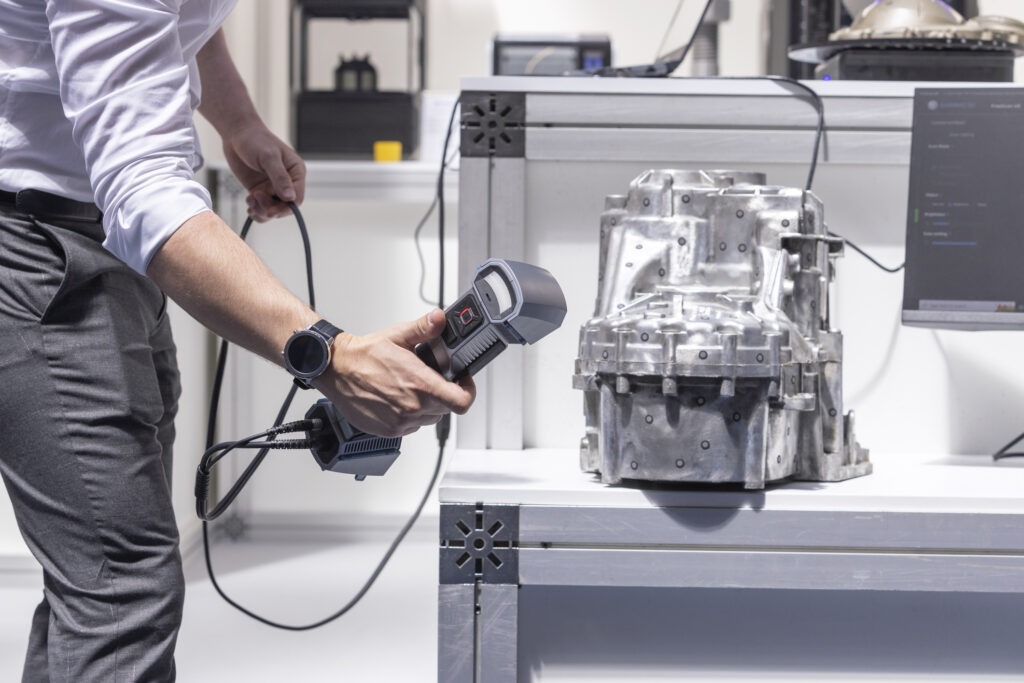

Reverse engineering, in the context of 3D scanning, is a meticulous process that involves the extraction of detailed information from 3D scan data.

This approach allows for the creation of a digital model of an existing object. Through 3D laser scanning technology, the physical object is precisely captured and translated into a CAD file, providing engineers, designers, and manufacturers with a versatile and accurate representation.

Reverse engineering services hold a crucial role in the realm of manufacturing.

Achieve Full Functionality in Your 3D Models

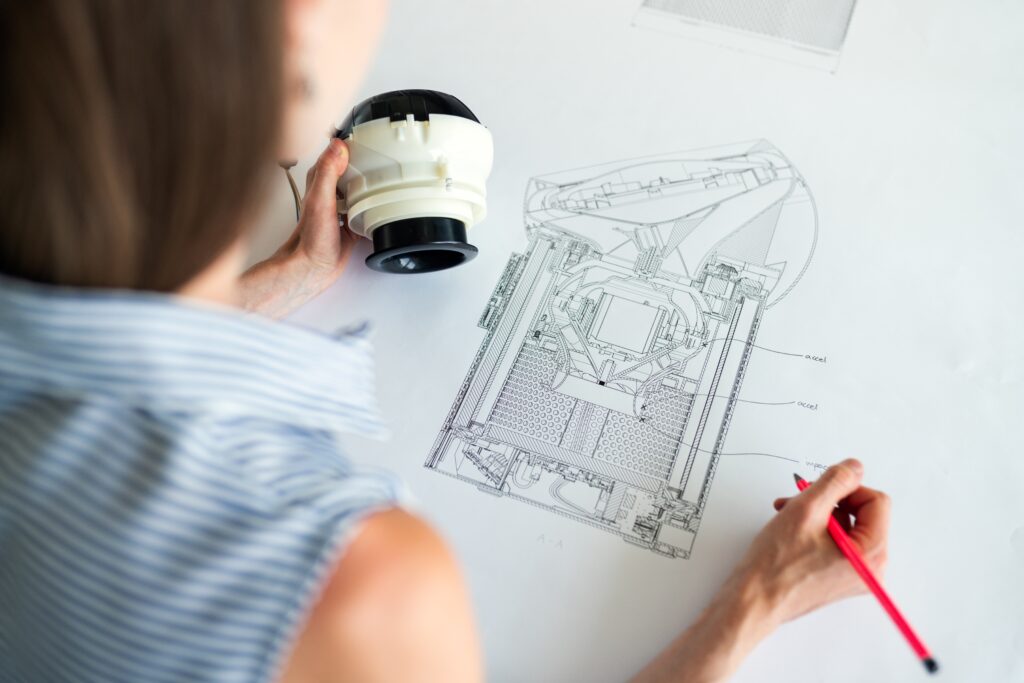

The reverse engineering process becomes invaluable when current 3D models are unavailable or have been lost over time. When combined with 3D scanning services, it enables the conversion of 3D scan data into a fully functional digital model that can be manipulated, flexed, and rotated.

The precision of data obtained through 3D laser scanning proves exceptionally beneficial for product design within CAD software, aligning seamlessly with your manufacturing objectives to create a tangible real-world product concept.

Reverse Engineering

-

Mesh to CAD Conversion

-

STEP IGES XT Delivery

What Are the Benefits of 3D Scanner Reverse Engineering Services?

Combining 3D laser scanning with reverse engineering offers an unparalleled advantage.

While reverse engineering scan data can be time-intensive, it yields the most polished and intricately detailed model achievable.

File Creation

The process of reverse engineering 3D scan files involves isolating critical project data and offering precise export choices like STEP, IGES, and XT for manufacturing and alterations.

By drawing CAD files based on precise scan data, your files also include this amount of detail.

Ultra-Precise 3D Models

The technology of 3D scanning excels at capturing intricate details and precise dimensions of an object with remarkable accuracy. This precise data capture forms the cornerstone of reverse engineering services.

Reverse engineering services offer high-resolution modeling, ensuring precise dimensions and volumetric accuracy. This includes the representation of crucial surface data such as ID, OD, and other essential measurements

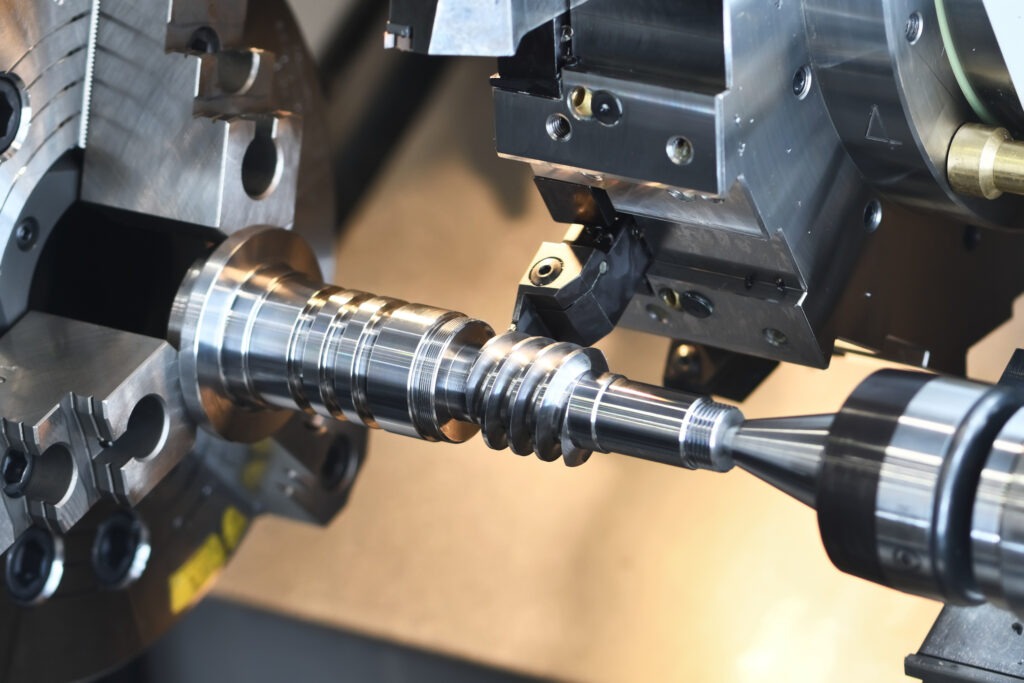

Manufacturing

We provide all reverse engineering files in universally compatible formats, including STEP, IGES, and XT. These files are readily adaptable for programming across a wide spectrum of manufacturing processes, including machining, laser cutting, injection molding, forming, and more.

Our team possesses the capability to locate a suitable manufacturer and manage all logistics aspects of your project.

Reverse Engineering F.A.Q

Our reverse engineering services are priced at $115 per hour, and this includes the creation of 3D CAD files in STEP, XT, or IGES file formats.

Reverse engineering services involve creating a 3D model, using 3D scan data as a reference. This 3D scan data is exceptionally precise, capturing intricate details and dimensions down to the thousandth of a millimeter.

Our reverse engineering services result in the creation of a CAD file. The most frequently used file formats we can provide include STEP, IGES, and XT. We also have the capability to export in various other formats to meet your specific needs.

Our reverse engineering services culminate in the generation of a CAD file. The primary file formats we commonly offer are STEP, IGES, and XT. Furthermore, we possess the flexibility to export in a wide array of other formats tailored to your specific requirements.

We can 3D scan your project while you wait. Once that data is collected, the part is no longer needed. Many clients ship in their part.

Services offered include mobile 3D scanning, data analysis, consultation for product development, and CAD design services.

Work With Tangent Solutions

Premiere 3D Scanner Reverse Engineering Services, CAD design, and Product Development Consulting.