3D Product Scanning Services

State-of-the-Art 3D Product Scanning Services

When precision and meticulous detail are crucial for your design endeavors, our 3D product scanning services grant you access to cutting-edge laser scanning technology, arming your team with the ultimate resource to digitally recreate real-world objects.

No project is beyond our capabilities, regardless of its size.

Our team of 3D design engineers is prepared to transform your grand concepts into tangible reality by delivering precise digital renditions, facilitating more streamlined product development. Most projects can be scanned upon arrival and swiftly returned, eliminating any disruptions to your production timeline

Accuracy Up to 0.02mm

3D Laser Scanning

-

Ultra-precise Accuracy

-

In-house in Our Office

-

Same Day Service

What Can You Achieve With

3D Product scanning Services?

3D scanning is a technology that captures the physical world in three dimensions, creating digital representations of objects, environments, or surfaces. It has a wide range of applications across various industries and can achieve several important outcomes,

Conceptulization

3D scan data provides a highly accurate and tangible representation of physical objects in a digital format, making it easier to conceptualize designs before moving to manufacturing. Data can also be used for rapid prototyping and 3D printing to verify fitment.

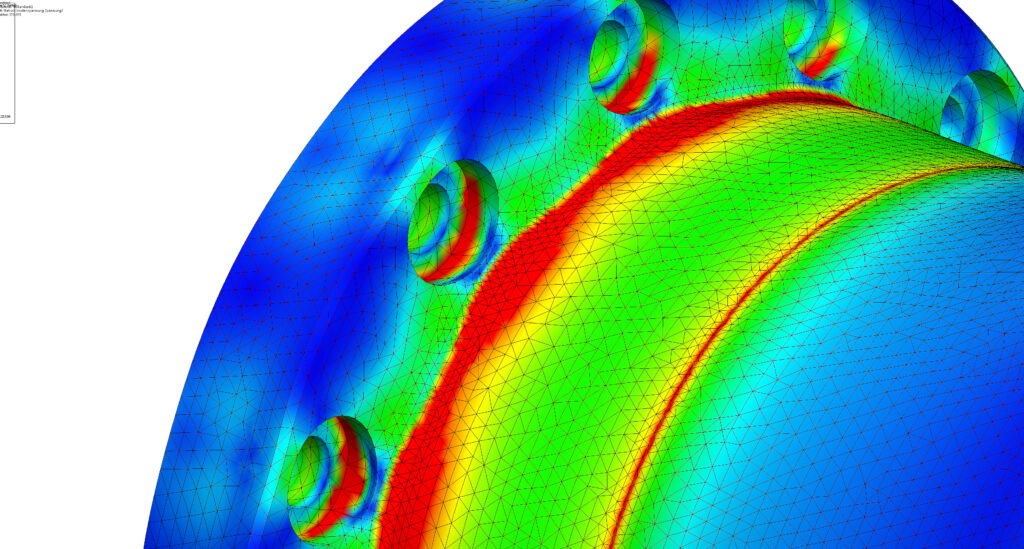

Quality Control Applications

Ensure the project’s quality prior to initiating manufacturing. We have the capability to conduct a meticulous comparison between the scan data and your initial CAD models, identifying any disparities or irregularities.

Manufacturing

All reverse engineering files are delivered in universal format; STEP, IGES, and XT. These files are seamlessly ready for programming for various manufacturing processes including machining, laser cutting, injection molding, forming, and more.

Our team can also source a manufacturer and handle all logistics.

The 3D Product Scanning Services Workflow

3D Scanning

For projects small or large, digital data is created in mesh format by way of a 3D laser scanner. 3D laser scanning is non-invasive and ultra-precise

File Creation

Scan data initially created in STL format, ready for reverse engineering to STEP, IGES, and XT format. Manufacturing projects will need CAD files.

Quoting

Once appropriate files are created, they can be sent to your manufacturer of choice for quoting; both domestic and international.

Modifications

When prototypes are produced, any changes can be determined and quickly changed in CAD software.

Marketing

Scan and CAD data can be used for various marketing avenues. 3D animations, virtual reality for eCommerce, and creating a buzz.

Production

Congratulations, your design is in production! Utilizing 3D laser scanning guarantees an exceptionally precise product.

F.A.Q

Our 3D product scanning services start at an hourly rate of $155. This rate applies specifically to in-house scanning procedures carried out within our office premises by our skilled technicians.

There is a one hour minimum for in-house scanning but most projects we can complete within that timeframe. Most projects can be dropped off in the morning and picked up before end of day.

3D laser scanning works by preparing laser triangulation. The object to be scanned is prepared with reflective targets that the scanner records by bouncing lasers on and back to the scanner. Between these targets, a digital mesh is recorded, identifying different surfaces, dimensions, and features. This scan data digitally records all that it sees into a 3D model.

Immediate data from 3D laser scanning is prepared in the native software. All scan data must be post processed with the quickest files being prepared as STL and OBJ files. Scan data can be reverse engineered to create CAD files.

Tangent Solutions main office is located in Irvine, in the heart of Orange County, Southern California. Our services are available to all domestic and international clients as our technology is completely mobile.

Mobile 3D scanning services, data analysis, product development consulting, CAD design services, and reverse engineering.

Depend on Tangent Solutions

Top-tier 3D product scanning, CAD design, and product development service.