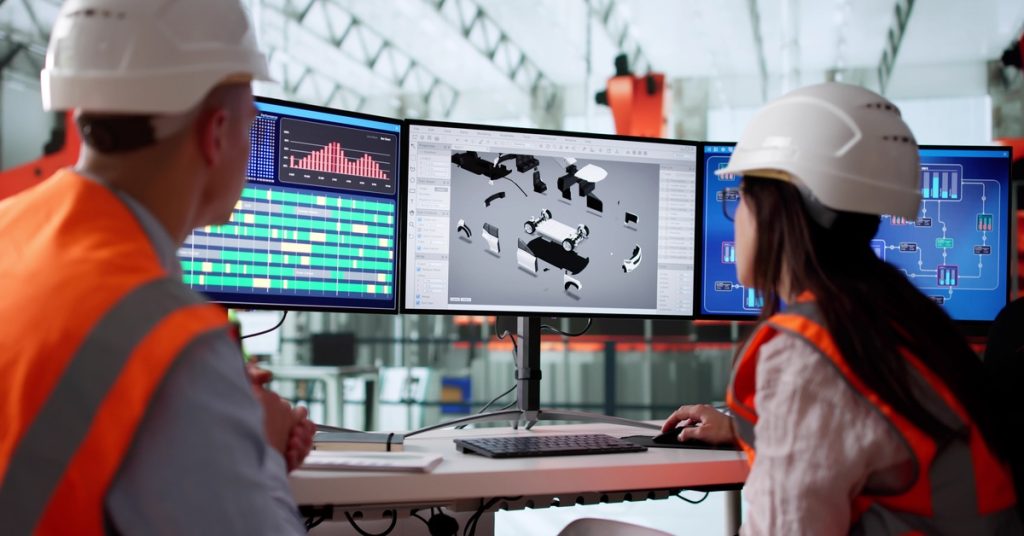

The Difference Between 3D Modeling and 3D Scanning

Even though 3D modeling and scanning might seem similar, there’s a lot that differentiates them. This guide explains each of their unique features.

5 Ways Product Engineering Can Accelerate Your Go-to-Market Strategy

Instead of designing, you should be working on your business. Outsourcing product engineering tasks—from initial CAD design to prototyping and production—offers numerous advantages. The possibility of creating a product line is easier than ever with globalization. Manufacturing costs have decreased, and access to overseas supplies has improved, leading to better product margins. Modern design and […]

How 3D Scanning Helps Recreate Famous Artwork

Recreating famous artwork is not easy, but with the use of 3D scanning, it can be. Let’s take a look at how this process is beneficial in the world of art.

How the Healthcare Industry Uses 3D Scanning

3D scanning technology is revolutionizing many industries, and healthcare is no exception. Learn more about its impact in this quick overview.

5 Reasons To Reverse Engineer Your Automotive Parts

Organizing a memorial is tough, and you should put careful consideration into it. Here are some key factors in selecting memorial décor for a loved one.

What To Consider When Hiring a 3D Scanning Company

There are many factors that go into finding a 3D scanning company that aligns with your business needs. Our guide carefully breaks each of those down for you.

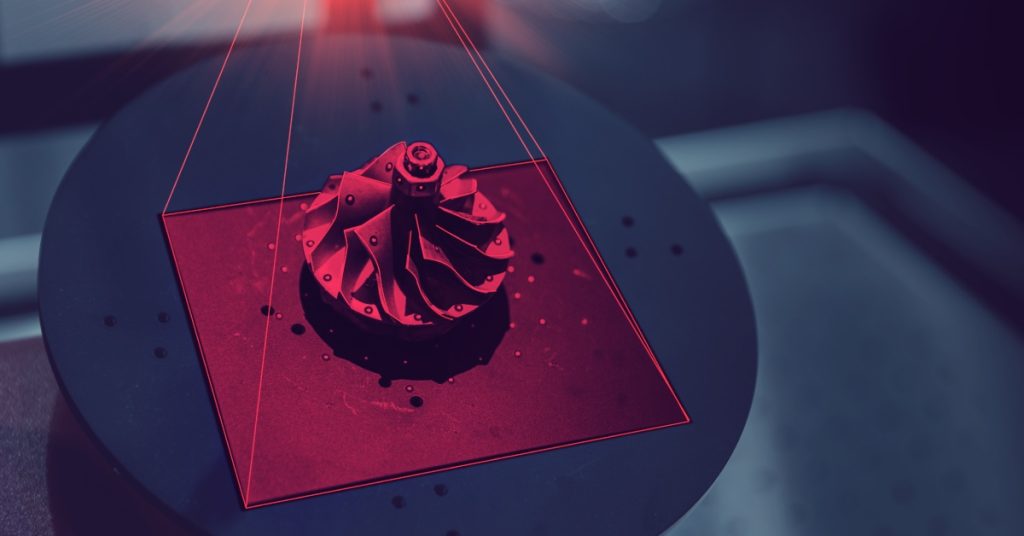

The Benefits of Laser Scanning for the Oil and Gas Industry

Oil and gas companies can benefit in a variety of ways from the use of laser scanning. Here’s a deep dive into what that could look like for your company.

Mesh vs. CAD Files: The Important Differences To Know

There are quite a few notable differences between mesh and CAD files. To better understand them yourself, this guide is here to walk you through them.

Case Study: On-site, Large Format 3D Scanning for Bayliss Machine & Welding

Client: Bayliss Machine & WeldingLocation: Birmingham, AlabamaServices: Mobile 3D Scanning, Reverse Engineering, 2D Print Creation Overview Tangent Solutions specializes in large-format 3D scanning, reverse engineering of legacy parts, and on-demand CAD support. Our team travels across the U.S. offering fully mobile 3D scanning services —making it easy to support clients in the field, shop, or […]

Why More Companies are Using Reverse Engineering in Manufacturing

In today’s fast-paced manufacturing environment, many companies are turning to reverse engineering in manufacturing to regain control over their product data, streamline production, and shorten development timelines. Whether you’re a manufacturer who no longer has original CAD files or an engineer dealing with product variations introduced during overseas production, reverse engineering can provide an accurate […]