3D scanning has provided design engineers a faster way to create 3D files for any existing project. These files are needed for various engineering projects. 3D laser scanning for reverse engineering purposes is the fastest way to create these files when none exist or when products vary greatly from their original model.

What is 3D laser scanning?

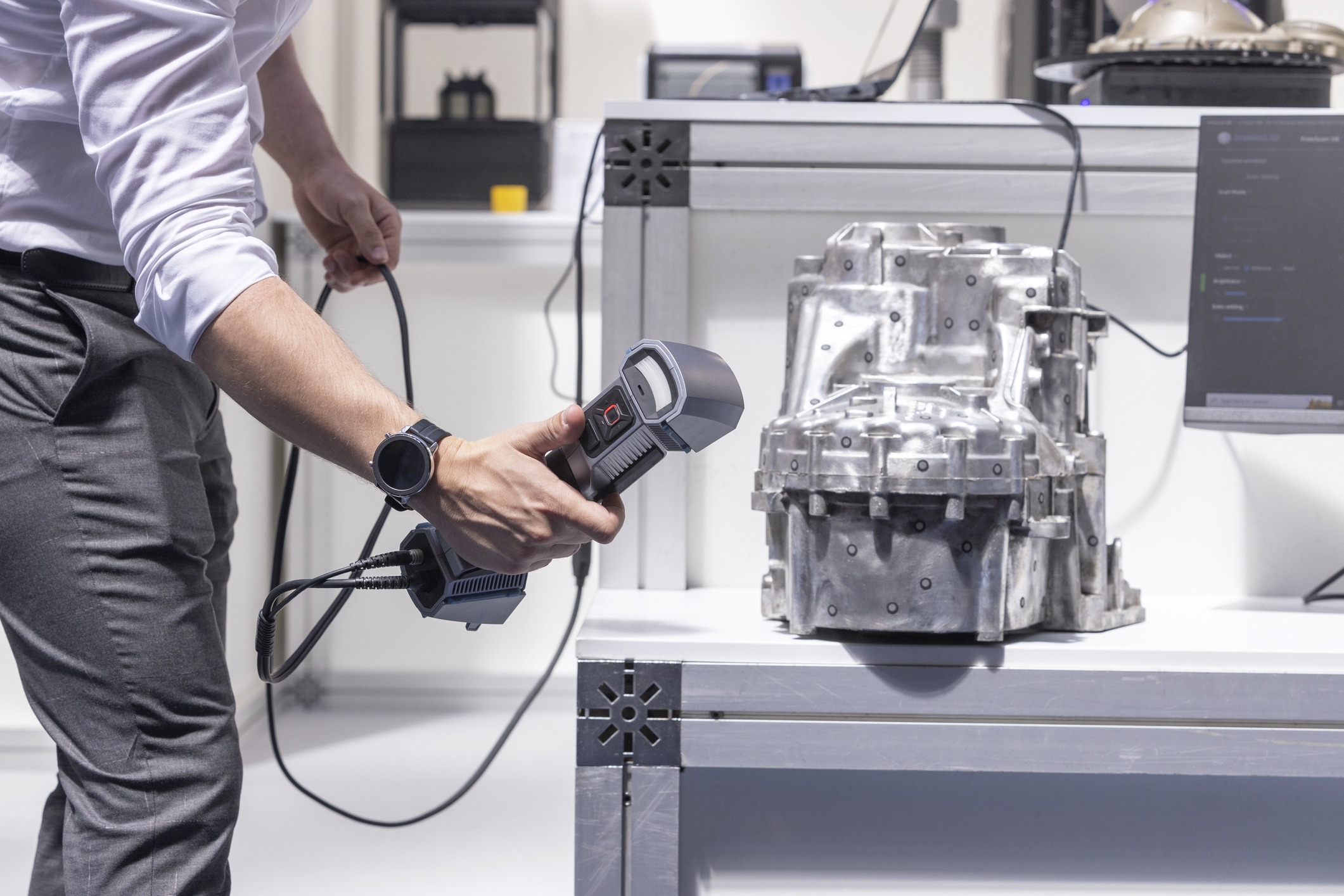

3D laser scanning is a data collection technique that uses a series of laser lights to digitally record the outlines of physical objects. A 3D laser scanner captures fine details as well as shapes and patterns with extreme precision.

as shapes and patterns with extreme precision.

Scan data is then employed to transform object outlines into three-dimensional models for various applications including 3D laser scanning for reverse engineering. With the data obtained by the scanner, these objects may now be replicated using 3D printers.

The technology provides several benefits for engineers in various sectors, and we will highlight some of the most important ones in this post. Read on to learn about the primary benefits of 3D laser scanning for reverse engineering.

1. 3D Laser Scanning for Reverse Engineering Saves Time

Gone are the days of using calipers to try and reverse engineer a project. 3D laser scanning for reverse engineering greatly accelerates the data collection process with accuracy.

By way of passing lasers over an existing surface, a mesh file is created that reports detail of the surface down to the thousandth, of a millimeter. What used to take hours of guessing with calipers, takes minutes with a 3D scanner.

Scan data that is collected is then reverse engineered in CAD software. Using the mesh as a guide, a CAD engineer can then draw the project to the exact measurement of the scanner’s data.

A company can have CAD models of a project in a business day rather than days which allows for prototypes to be manufactured even faster.

3D laser scanning is a fairly new technology that allows businesses to conserve engineering time which also increases profits in several ways. 3D scanning is non-invasive and has little to now downtime of the component being scanned.

There are a number of companies that provide 3D scanning. Professional 3D scanning services assist companies in creating exact 3D models with exact dimensions, eliminating engineering errors in manufacturing; costing time and man hours.

2. Validate Fitment of Parts Before Production

3D laser scanning for reverse engineering can be used at the start of the design phase to create a CAD model of an existing project. It is also ideal to scan a component that will be modified or built onto.

Typically, design engineers have to work with or adapt designs to already-existing objects or existing CAD models. This can lead time fitment discrepancies.

By digitizing existing products, CAD files can test fitment inside CAD software, before they are manufactured. 3D scanning technology can assist in swiftly recording all of the quantifiable metrics of any physical entity, as well as ensuring that the pieces are constructed properly enough to fit.

As a result, parts reliably fit on the first attempt.

3. Fast, Thorough Data Collection

3D laser scanning collects important, high-precision data in the form of a point cloud which provides all vital measurements.

3D laser scanning for reverse engineering purposes is trusted because data recorded includes inner and outer diameter of holes. This is difficult to validate with traditional reverse engineering techniques.

Many 3D laser scanners are able to detect the smallest of details with some not even seen by the human eye. The 3D data obtained during the scanning procedure is so detailed that nearly every aspect is documented, making it also a great option for quality control applications.

The possibility of omission is diminished significantly, with a very low risk of mistake. 3D laser scanning for reverse engineering eliminates the need to consider human errors.

4. Quality of 3D Laser Scanned Files

3D laser scans are extremely useful for quality control because of the ability to visualize possible issues before they become too difficult to resolve. The data collected on an existing component is reverse engineered CAD file and then compared to existing files.

The actual project may differ greatly, visualizing a manufacturing problem or damage to part in service. 3D laser scanning is a useful and effective maintenance plan to validate the safe operation of components.

5. Long Term Benefits

3D laser scanning for reverse engineering data allows for a design engineer to validate designs as a project advances. It is common to have multiple variations in the design process.

3D scanning is used to detect such changes as well as catalog the variants. Using laser scanning throughout the process ensures that data at important phases in the project’s evolution is recorded.

This information monitoring and collection is useful once production is done and throughout quality control processes. Design engineers are always able to swiftly look back to the original model to see precisely where and when project components were put.

The scanned data can also be a valuable resource for asset management throughout the project’s life cycle.

Furthermore, because there is no need to deconstruct the entire structure if there is a design defect, the 3D model created by a laser scanner may be utilized to remodel the structure in the future.

Design engineers can simply reverse engineer new scan data and continue to build on the existing model. This is essential for greater performance and part alignment.

Sum Up the Benefits of 3D Laser Scanning for Reverse Engineering

Using 3D laser scanning for reverse engineering a physical object is incredibly beneficial for any engineering project.

Engineering professionals are able to save time with 3D laser scanning while ensuring that parts will fit together correctly, collect high-precision data, and verify quality as a project moves through its design phase.

There are many benefits of 3D laser scanning for reverse engineering purposes. With such quick and precise technology, there is no denying its importance throughout the whole process of bringing an engineering concept into existence by way of 3D laser scanning.