Understanding The Process, Speed, And Turnaround Time

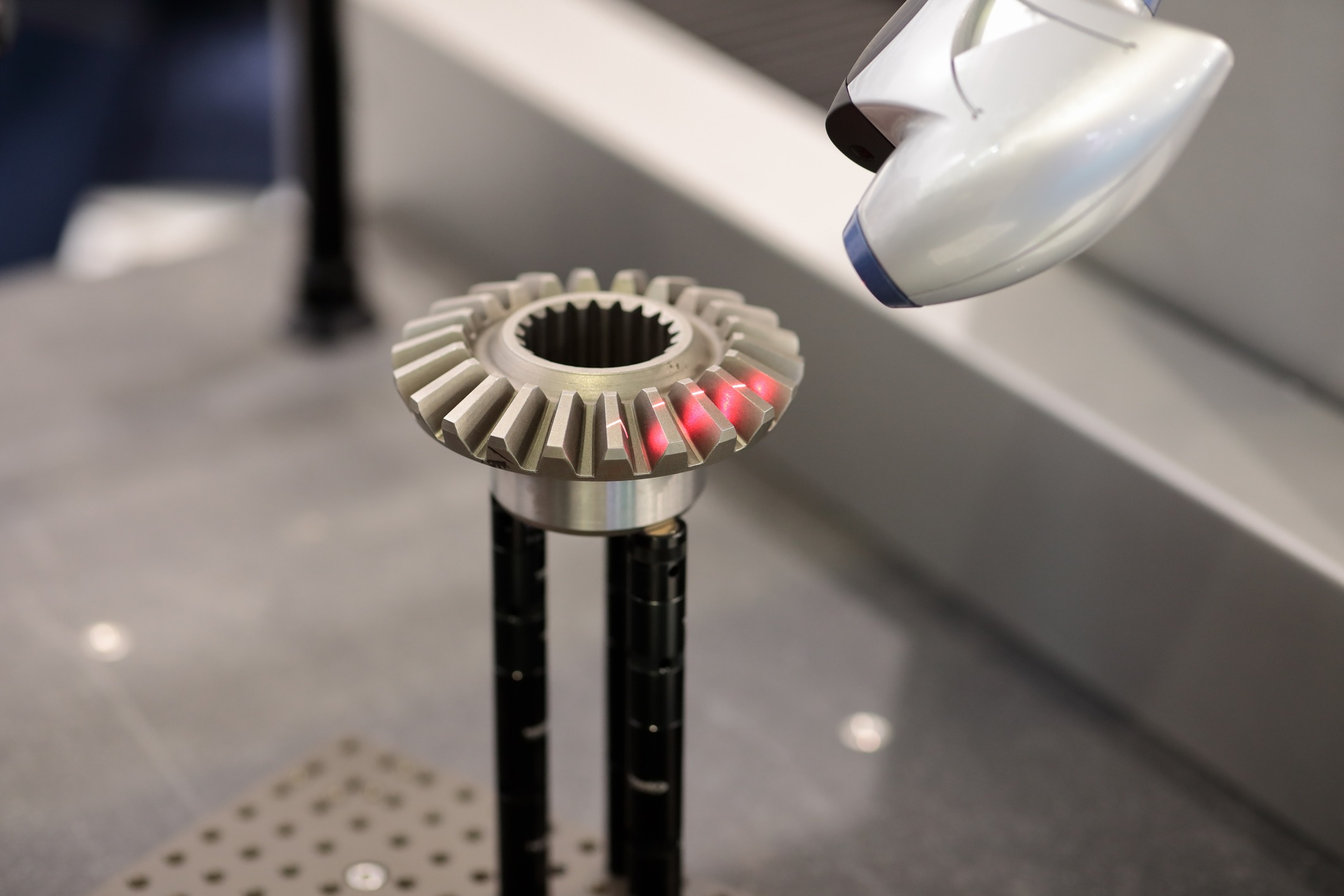

If you work in manufacturing, product design, or engineering, you’ve likely seen how powerful 3D scanning can be. It’s an essential tool for capturing precise measurements, accelerating development, and converting real-world objects into digital models.

But one of the most common questions we hear is: how long does 3D scanning take?

The answer depends on several factors — including the type of scanner used, the size and complexity of the object, and the level of detail required. Below, we’ll break down what affects scan speed, how long you can expect to wait for results, and what happens after scanning is complete.

What Is 3D Scanning?

3D scanning is the process of digitally capturing the geometry of a physical object. Unlike traditional photography, which captures color and texture, 3D scanning collects millions of data points from every angle — mapping an object’s exact shape, size, and surface details.

At Tangent Solutions, we use metrology-grade laser and structured light scanners to ensure precise data capture. Each scan produces a dense mesh or point cloud, which can later be refined into clean, usable 3D models for engineering or manufacturing.

How Long Does 3D Scanning Take?

Every project is different, but most scans take anywhere from 30 minutes to several hours depending on complexity.

Several factors influence scan time:

- Object Size – Small components can often be scanned in under an hour, while large machinery or vehicles require multiple passes and repositioning.

- Geometry & Detail – Complex surfaces, reflective materials, or deep recesses take longer to capture accurately.

- Resolution Requirements – Higher resolution scans collect more data points, resulting in greater accuracy — but also longer capture times.

- Surface Preparation – Certain materials (like chrome or glass) may need a light coating or markers before scanning, which adds setup time.

In general, our scanners capture between 500,000 and 1.5 million points per second, allowing us to digitize parts quickly while maintaining sub-millimeter precision.

Once the scanning phase is complete, the data moves into processing — a crucial step that determines how soon you’ll receive the final files.

What Happens After Scanning

After collecting the raw scan data, our engineers process and clean it before delivery. This includes:

- Aligning and Merging Passes – Combining multiple scans into one complete 3D dataset.

- Noise Reduction – Removing stray points or artifacts for a clean mesh.

- Hole Filling & Surface Smoothing – Creating watertight geometry for consistent measurements.

- Compression & Optimization – Reducing file size while retaining detail for easier file handling.

Depending on the size and complexity of the project, data processing can take anywhere from a few hours to several days. However, most clients receive their completed files within one to three business days.

File Output Options

We tailor deliverables to each client’s workflow. Tangent Solutions can provide:

- Raw Mesh Data (STL, OBJ) – Ideal for visualization or basic inspection.

- Cleaned Mesh Files – Smoothed, aligned, and ready for measurement.

- Rendered CAD Models (STEP, IGES, XT) – Fully reconstructed, editable geometry for design and manufacturing.

Our engineering team can also provide reverse-engineered CAD models directly from scan data, creating accurate digital twins ready for modification, simulation, or prototyping.

If you need ongoing support, we also offer post-processing and CAD modeling as part of our 3D Scanning Services — ensuring your data is fully usable across design, quality, and production workflows.

Turnaround Time Expectations

Most 3D scanning projects can be started the same day they arrive at our facility. For on-site scanning, we can typically deploy within days of approval.

Here’s a general timeline for standard projects:

| Project Type | Typical Scan Time | Average Turnaround |

|---|---|---|

| Small Parts & Components | 30–90 minutes | 1–2 days |

| Medium Assemblies | 2–4 hours | 2–3 days |

| Large Equipment / Vehicles | 4–8+ hours | 3–5 days |

| Reverse-Engineered CAD Deliverable | Varies by complexity | 3–7 days |

We pride ourselves on providing fast, accurate results while maintaining the highest data integrity.

Why 3D Scanning Is Worth the Wait

Even when a scan takes time to process, the benefits far outweigh the turnaround period. 3D scanning eliminates guesswork, reduces manual measurement errors, and provides the foundation for precise CAD modeling.

For manufacturers and designers, this means:

- Faster product development cycles

- Reduced prototyping costs

- Improved fitment and assembly accuracy

- Reliable documentation for quality control and future redesigns

Instead of weeks of manual measurement or re-creation, 3D scanning delivers an exact digital replica in a matter of hours — saving time, money, and resources.

Bringing It All Together

So, how long does 3D scanning take?

The short answer: not long — especially when done by experienced professionals with advanced equipment.

At Tangent Solutions, we use Creaform HandySCAN BLACK Elite scanners and expert post-processing workflows to deliver fast, metrology-grade results for everything from small components to large industrial assemblies.

Whether you need raw scan data, clean mesh files, or fully reverse-engineered CAD models, our 3D Scanning Services deliver the accuracy, speed, and flexibility your projects demand.