Tangent Solutions provides Nashville 3D scanning services for reverse engineering, CAD file creation, quality control reports, and more. For projects of all sizes, we have the ability to send a technician to your location or have smaller project scanned in our office.

With expertise in manufacturing, our on-site design engineers are able keep the productivity of your project in-mind throughout the design process.

Our 3D laser scanning platform is completely mobile, making it essential for large and remote projects. Technicians can be scheduled to be on-site in one business day. The scanning process is non-invasive and fast, minimizing downtime for your company. 3D scan data can be used to validate quality of manufacturing, create new products, and more.

Clients Benefits for Nashville 3D Scanning Service

To view samples of commonly delivered data files, click below.

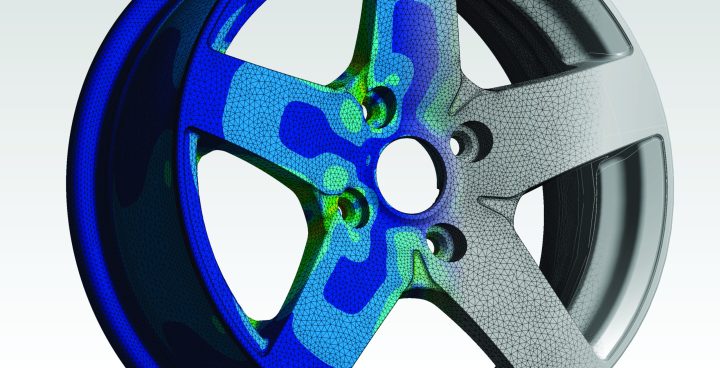

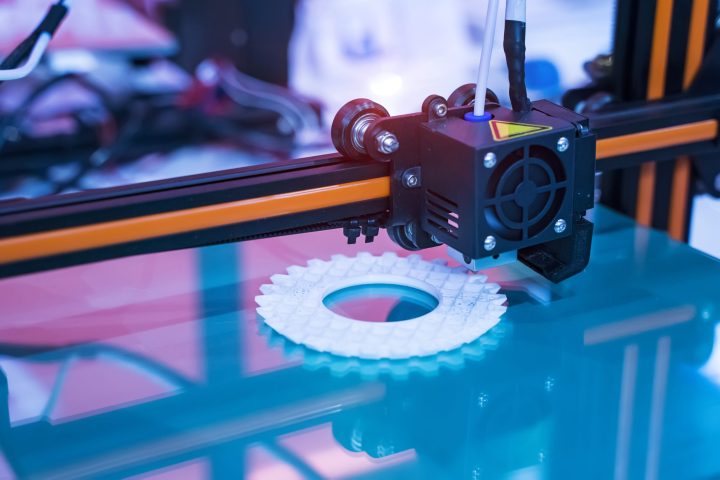

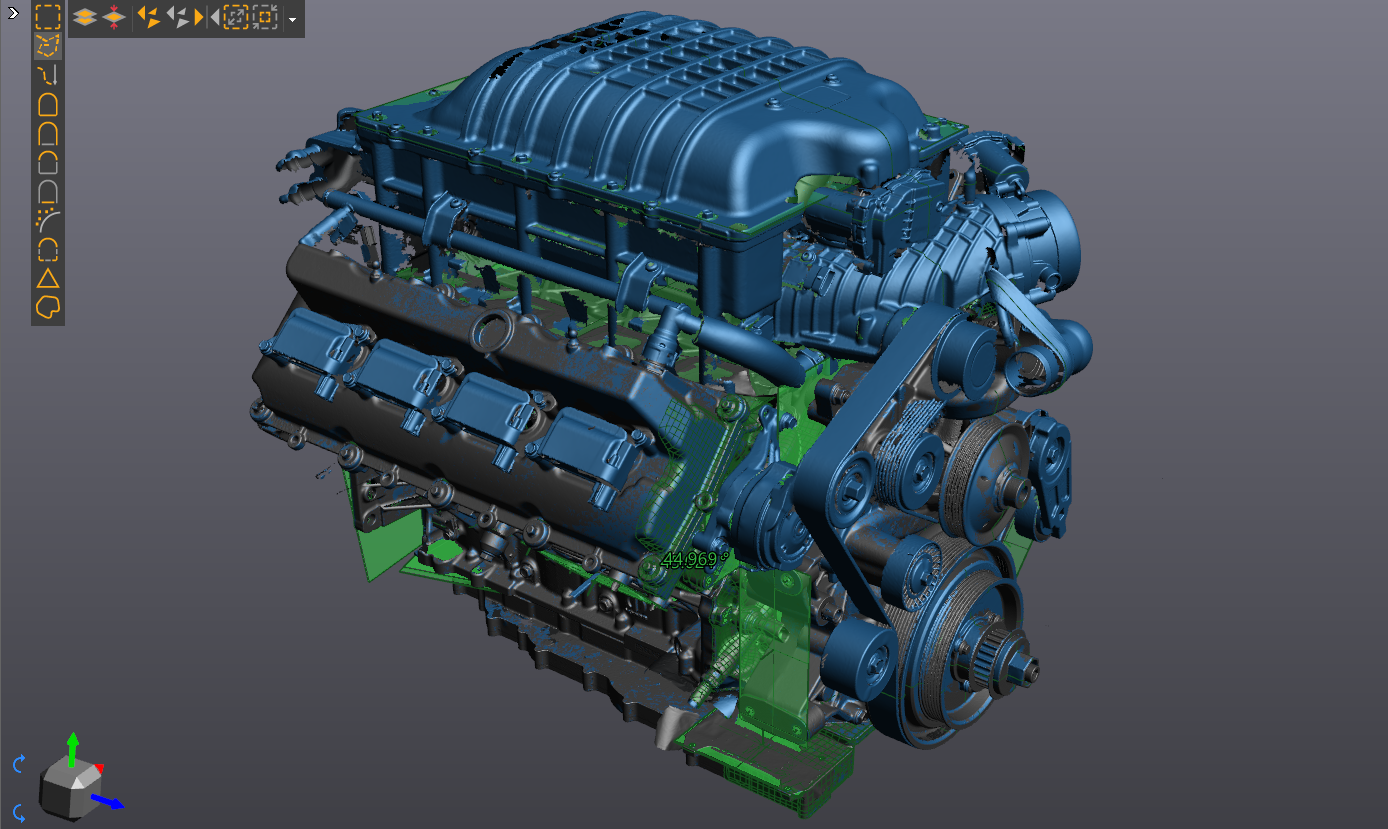

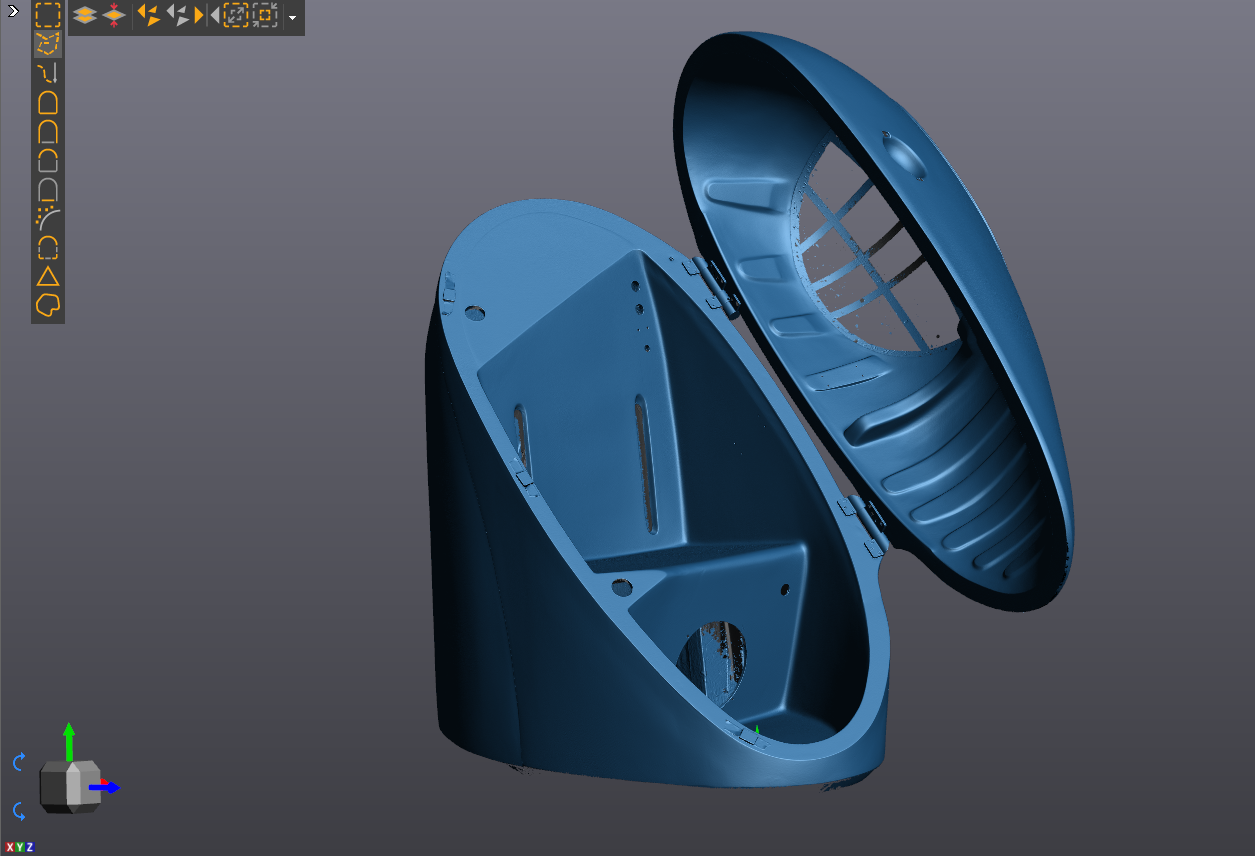

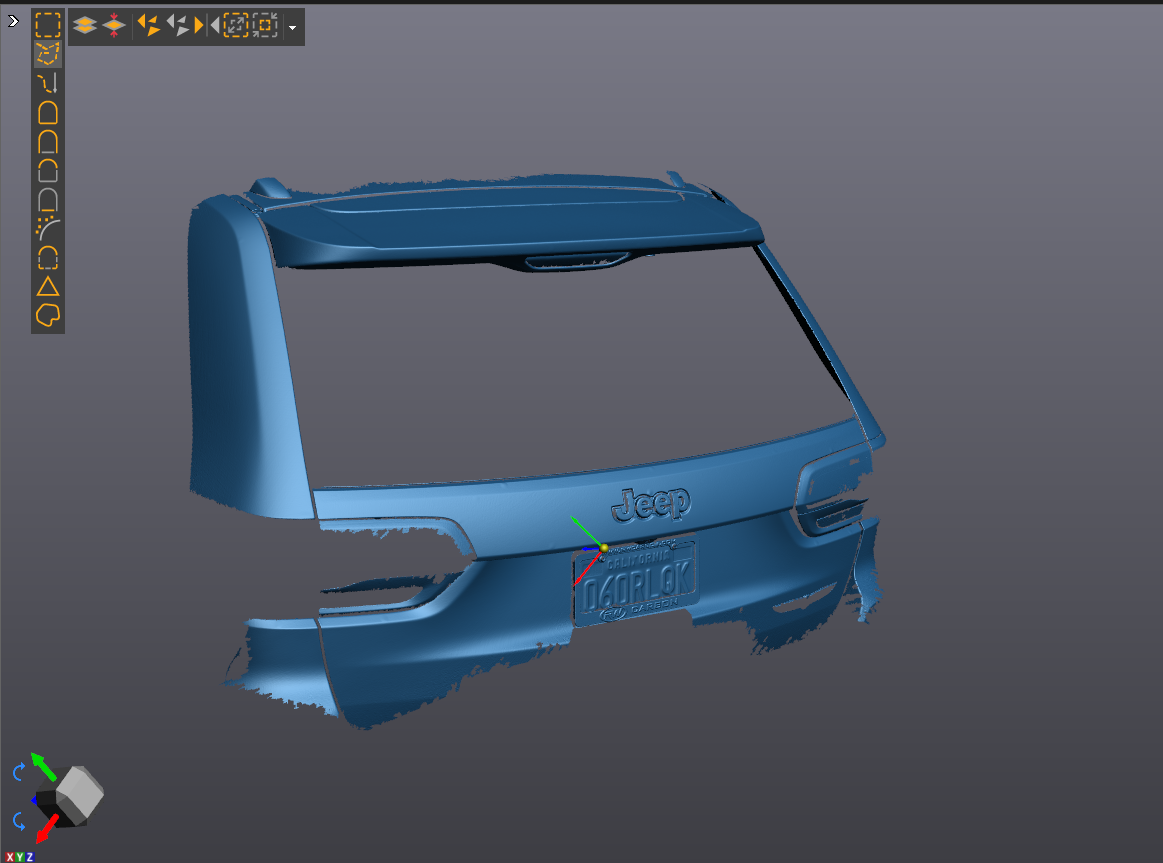

Depending your project goals, scan data can created in conceptual, mesh files, STL and OBJ, or revers engineered to produce functional CAD models in STEP, IGES, and XT.

In order to export, data must be post processed after scanning is completed. This includes clean up of erroneous data, geometric elements identified, and inconsistencies filled. This process does not augment the original shape.

For reverse engineered files, data represents dimensions accurately to the thousandth of a millimeter. This includes ID, OD, and other measurements.

We keep file sizes minimal without compromising quality. Scan data can be broken up and exported into individual files to keep computing times minimal.