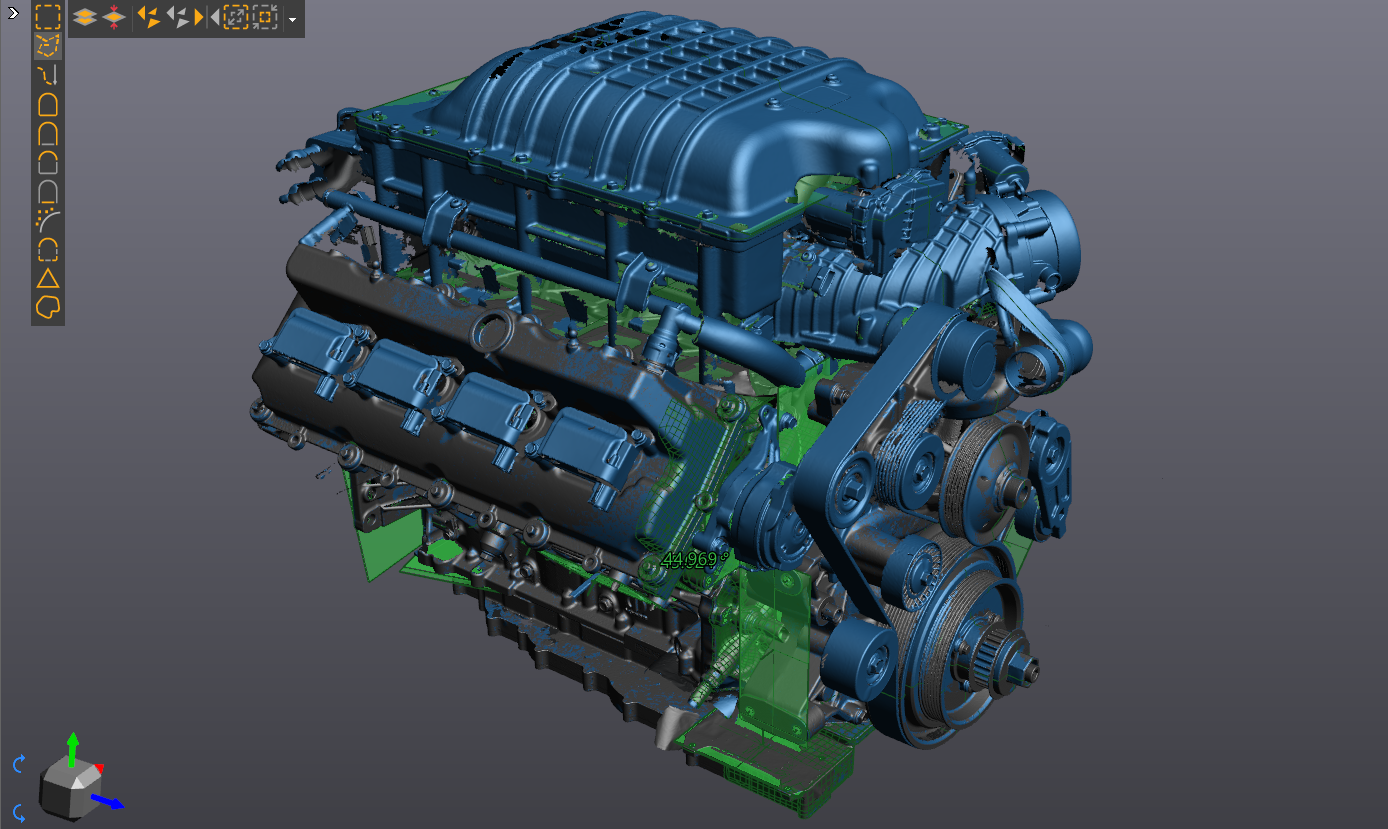

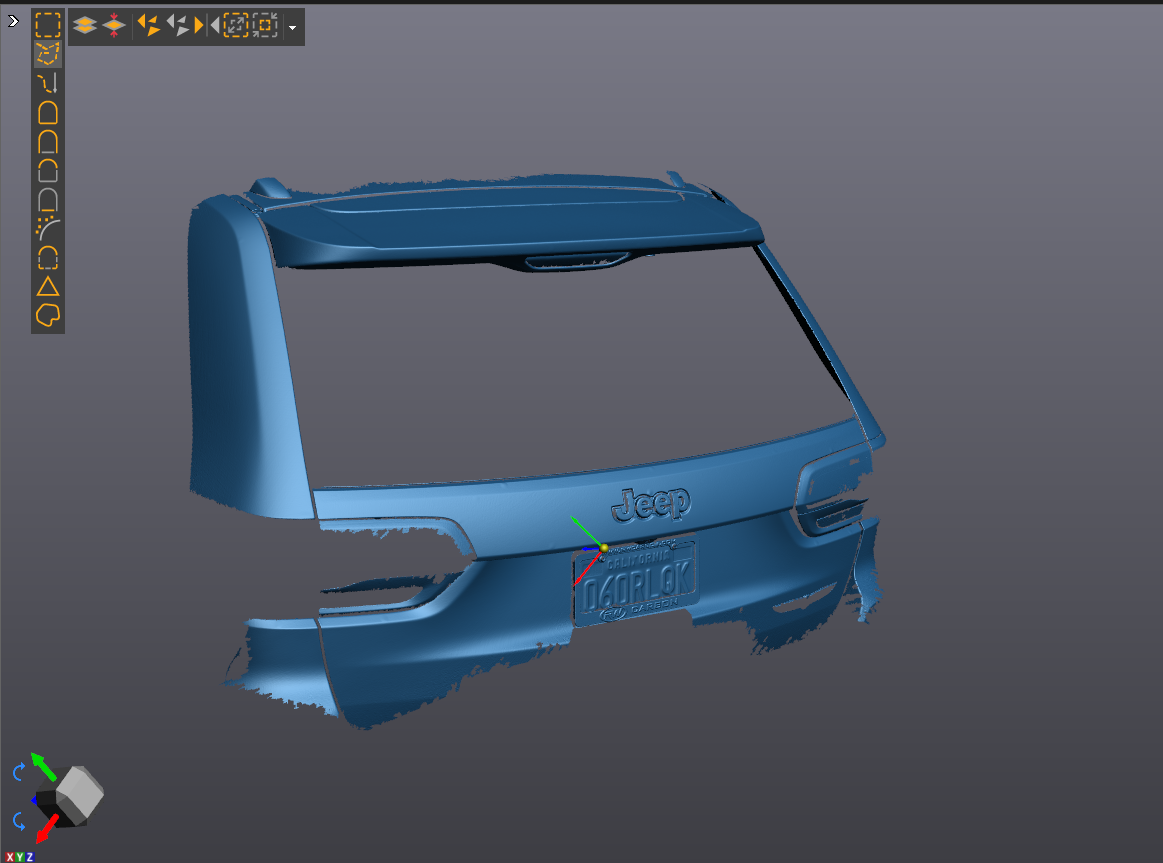

Detroit 3D scanning clients can rely on our technology for large and small projects. Our 3D laser scanning technology can digitize any existing surface to create 3D models, quickly and instantly. From airplane fuselages, to the smallest PCB board detail, our team has the ability to deliver reliable data.

Our 3D scanning services is used to create CAD files for manufacturing, quality control reports, data validation, and more. With a team of in-house design engineers, we specialize in manufacturing with each member originating from a production background.

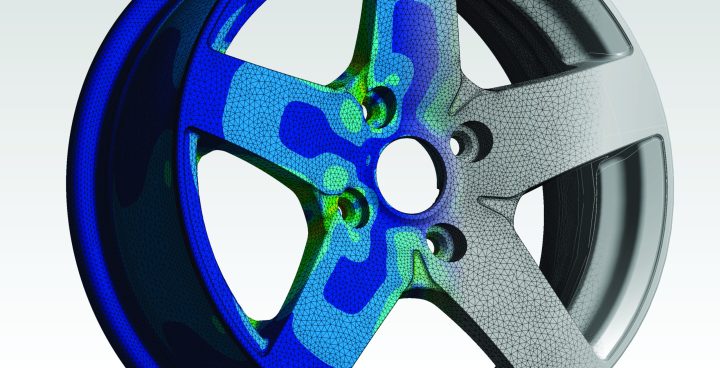

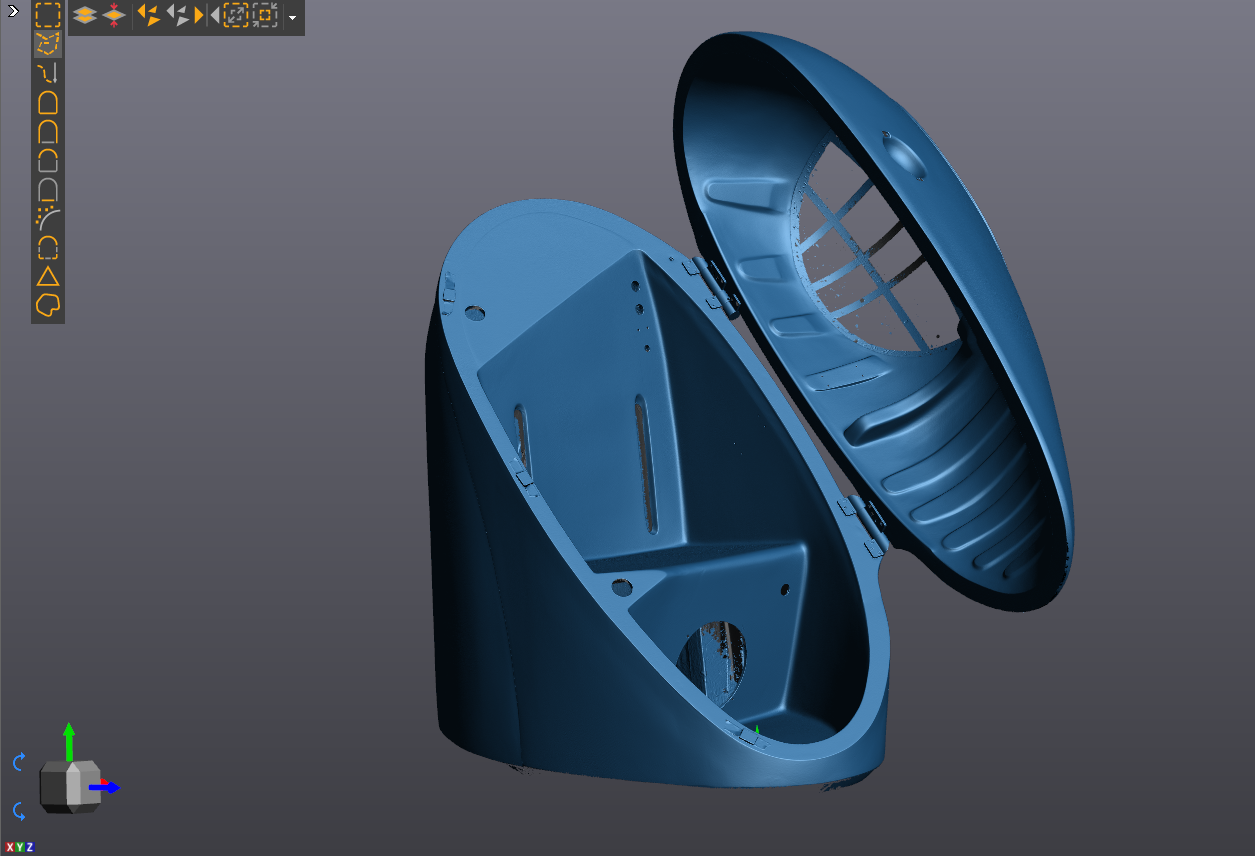

When you work with Tangent Solutions, the accuracy of your 3D files is dramatically increased. With the technology of blue light lasers, detail is unsurpassed with accuracy up to 0.02mm. Laser scanning is a no-touch process and can digitize any existing surface instantly. This data can be used to verify quality of a product, catalog legacy components, and modify existing designs.

Benefits of Detroit 3D Scanning Service

To view samples of commonly delivered data files, click below.

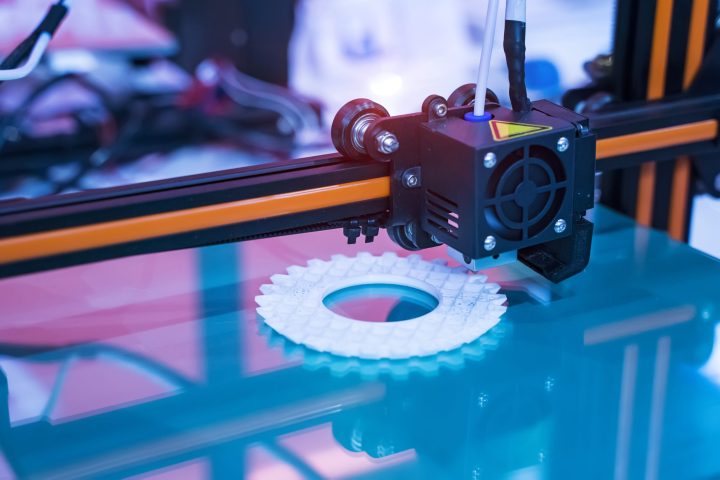

Initial scanning is created into STL or OBJ format. Reverse engineering can be completed to make STEP, IGES, and XT files.

Laser scanning produces data for everything it sees. Unwanted data is easily erased while holes can be filled to create smooth models.

Vital data points such as ID, OD, and other measurements are accurate up to 0.02mm.

Scan files can be itemized and exported individually to cut down on processing times.