3D scanning technology has revolutionized healthcare by enabling precise diagnoses, personalized treatments, and innovative solutions. Through its ability to create detailed digital models of physical structures, this technology allows medical professionals to address patient needs with an unparalleled level of accuracy. We’ll provide an in-depth look at how 3D scanning is transforming various sectors within healthcare.

Prosthetics and Orthotics

Custom prosthetics and orthotic devices rely heavily on precise measurements, and traditional methods often involve time-intensive, manual processes. 3D scanning disrupts this norm by capturing detailed and accurate digital images of a patient’s anatomy in a matter of minutes.

For example, medical professionals can craft a prosthetic limb to fit the exact shape of a patient’s residual limb, ensuring natural movement and comfort. Similarly, they can precisely tailor orthotics, such as insoles or scoliosis braces, to a patient’s unique physical needs. By adapting closely to a patient’s anatomy, these devices are not only more effective but also more comfortable to use over extended periods.

Surgical Planning and Simulation

Surgical procedures often require navigating complex anatomical structures, particularly in cases involving fractures, tumors, or congenital abnormalities. 3D scanning generates detailed imaging, frequently sourced from CT or MRI technologies, which medical professionals can convert into precise digital or printed models.

That means in craniofacial surgery, teams can take a 3D-printed replica of a patient’s skull, which allows surgeons to study the anatomy in detail, identify specific challenges, and rehearse the procedure. Orthopedic surgeons use similar tools to visualize fractures, enabling precise alignment and reconstruction of bones. These capabilities minimize unforeseen challenges during surgery and enhance both the safety and efficiency of the procedure.

Dental Applications

The dental and orthodontic fields have adopted 3D scanning to replace slow, uncomfortable traditional molds with fast and precise digital impressions. Using intraoral scanners, practitioners capture detailed scans of a patient’s teeth and gums, which they then use to create dental appliances.

These images allow for the creation of crowns, bridges, veneers, and orthodontic aligners with exceptional accuracy. Orthodontists also benefit from 3D scans in planning long-term treatments, using them to predict how teeth will shift over months of realignment. Digital workflows enhance precision and allow dentists to deliver faster, higher-quality results to patients.

Medical Imaging and Diagnostics

Medical imaging forms the backbone of diagnostics, and 3D scanning technologies, such as CT, MRI, and ultrasound, have extended their capabilities significantly. These imaging systems provide volumetric data that medical professionals can digitally reconstruct into comprehensive 3D models of internal organs and structures.

For instance, oncology teams utilize 3D imaging to analyze a tumor’s size, location, and relationship to critical tissues, enabling the development of more targeted treatment plans. Similarly, cardiologists rely on 3D echocardiograms to visualize heart function, identifying blood flow irregularities or structural defects. This advanced level of imaging elevates diagnostic accuracy and enables more effective treatments.

Custom Implants

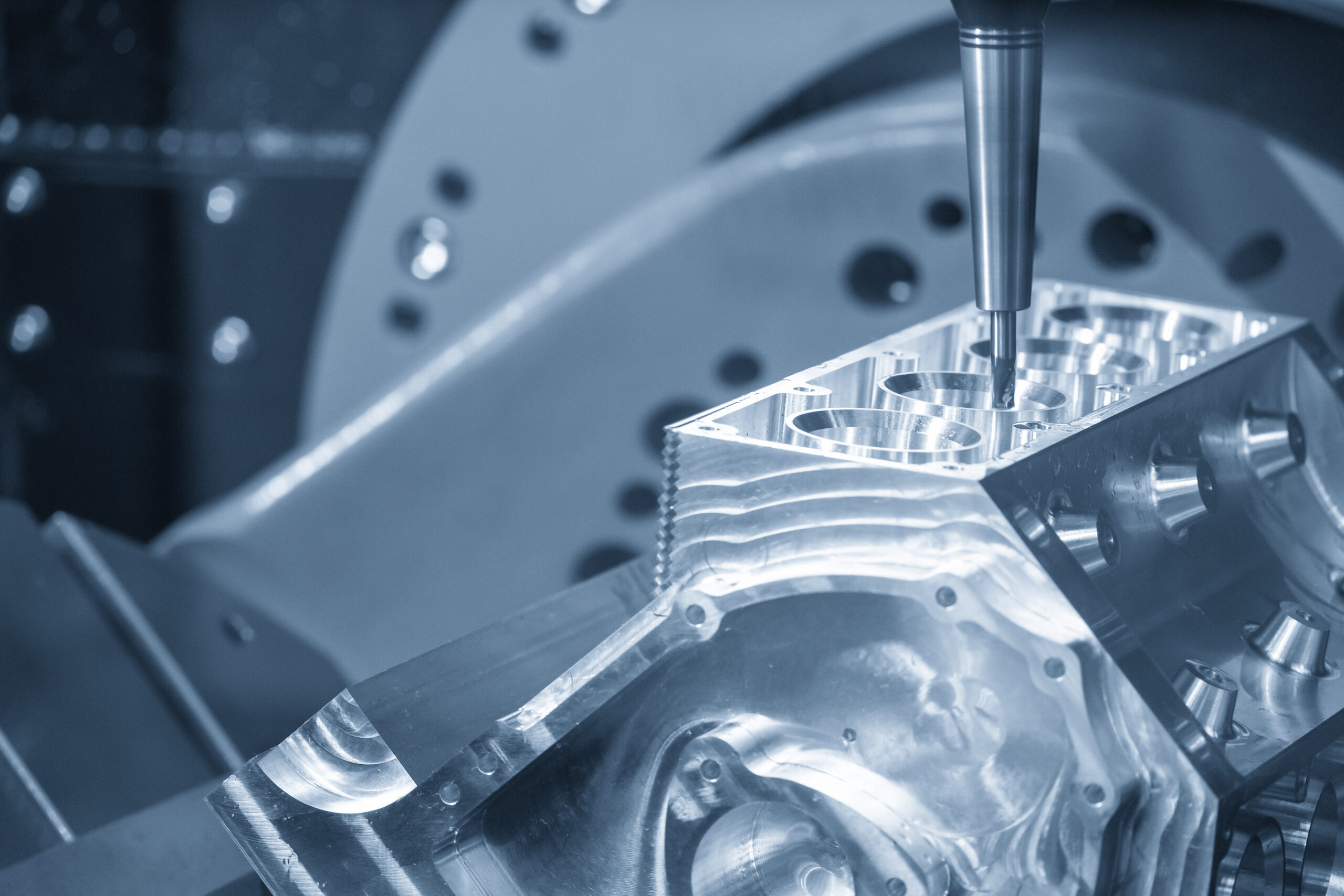

With 3D scanning, the healthcare industry can now use this tech to design implants that fit a patient’s specific anatomy with unmatched precision. They use these scans to capture the dimensions and shape of the targeted area and apply this data to create patient-specific devices.

Since many facial reconstructions after trauma often involve titanium plates, professionals can design them with the aid of 3D scans for exact alignment and aesthetic restoration. Similarly, in orthopedic applications, custom knee or hip implants are developed to match the patient’s biomechanics. This tailored approach reduces the risk of complications and leads to better functional outcomes for a wide array of surgical interventions.

Rehabilitation and Physical Therapy

Recovery from injuries or surgeries often involves supportive devices like braces, splints, or orthotic aids. 3D scanning technology expedites the design and production of these tools, ensuring that they are accurately customized to meet each patient’s unique needs.

For patients recovering from a knee injury, 3D scans can aid in creating a precisely fitted brace that stabilizes the joint without limiting natural movement. Foot-related issues like plantar fasciitis or gait disorders can also benefit from custom orthotic insoles crafted using detailed foot scans. These solutions not only support recovery but also improve patient comfort and adherence to treatment plans.

Cosmetic and Reconstructive Surgery

Detailed 3D scans of a patient’s face or body provide surgeons with essential data for planning cosmetic and reconstructive procedures. Rhinoplasty, for instance, benefits from this technology by enabling surgeons and patients to visualize expected results, ensuring everyone is on the same page before surgery begins.

Reconstructive surgery and congenital conditions are other areas where 3D scanning proves invaluable. For these procedures, medical professionals can design custom implants or grafts to restore both function and appearance with remarkable accuracy. The incorporation of such tools streamlines preparation and significantly enhances outcomes.

Education and Training

3D scanning has become a critical asset in medical education by providing students and trainees with lifelike models based on real anatomical data. Universities and hospitals use scans to produce 3D-printed replicas of human anatomy, such as organs, bones, or pathological conditions.

These models allow students to study physical structures in ways traditional textbooks cannot provide. For surgeons in training, they offer an interactive, hands-on method to practice complex procedures. Since these surgical simulations based on 3D scans help bridge the gap between theoretical learning and real-world application, teams will be able to help new professionals build confidence and refine skills like never before.

Wound Care and Monitoring

Chronic wounds, particularly diabetic ulcers or pressure sores, require constant monitoring to ensure proper healing. 3D scanning can assist here by providing a precise solution that measures depth, surface area, and volume with consistency over time.

Traditional methods often yield inconsistent data and fail to capture a complete picture of the wound’s dimensions. By using 3D scans, clinicians gain access to reliable, repeatable data that supports more informed treatment adjustments. This leads to more effective healing strategies and improved outcomes for patients with long-term care needs.

Bioprinting and Tissue Engineering

3D scanning has paved the way for advancements in bioprinting and tissue engineering, fields that are shaping the future of personalized medicine. By capturing exact anatomical data, 3D scanning enables the creation of tissue scaffolds that are custom-designed for a specific individual.

An example of this innovation can be seen in the development of artificial skin for burn victims. Scans of the damaged area guide the creation of scaffolds that match the contours of the patient’s body, increasing integration success rates. These techniques are also being explored for creating complex, functional organs, offering promising solutions to challenges like organ shortages and transplantation compatibility.

How We Can Help

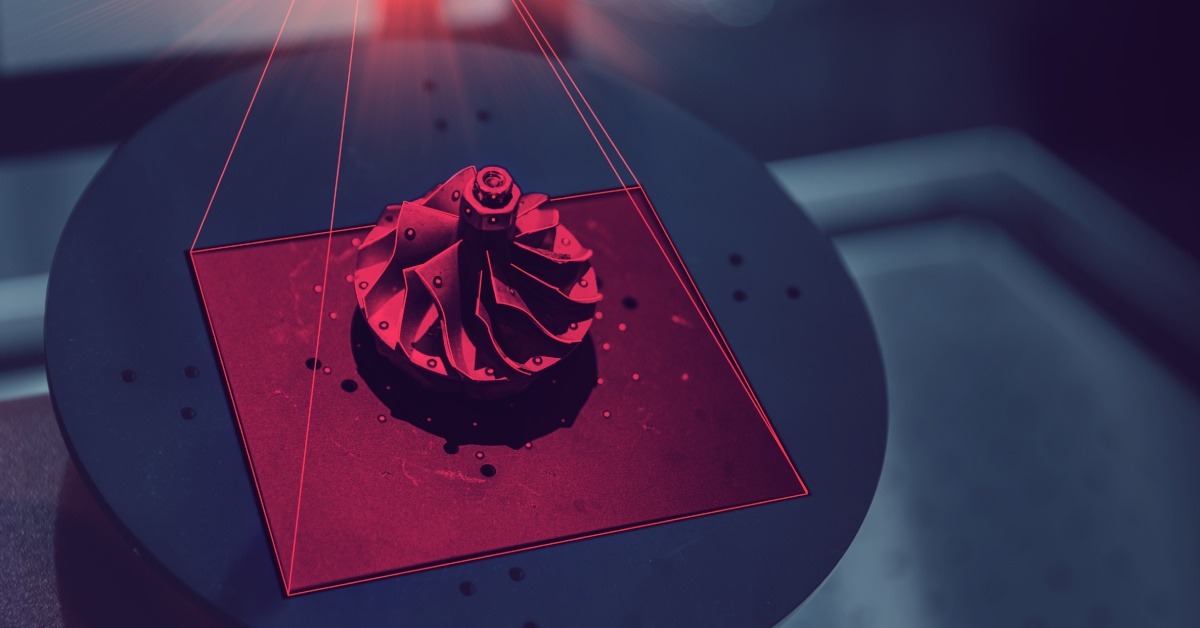

While many medical facilities might already have the machines needed to scan objects into a computer, not all do. Even the ones that have this kind of technology still might need an external source to help them with some processes. Either way, Tangent Solutions is your answer. We are a full-service 3D laser scanning company that can help you turn any physical object into a digital scan. Reach out to our team to learn more about how we can assist you.