Manufacturing, design, and healthcare industries are experiencing a digital transformation that’s reshaping how professionals approach product development and analysis. At the heart of this evolution are two powerful technologies: 3D modeling and 3D scanning. While both create three-dimensional digital representations, they serve distinctly different purposes.

Understanding the fundamental differences between 3D modeling and 3D scanning is crucial before starting your next project. Whether you’re developing a new product from scratch or need to digitize an existing object, the appropriate approach can benefit your timeline, budget, and results. Let’s explore how these complementary technologies work and which method delivers the best outcomes based on the task.

What Is 3D Modeling?

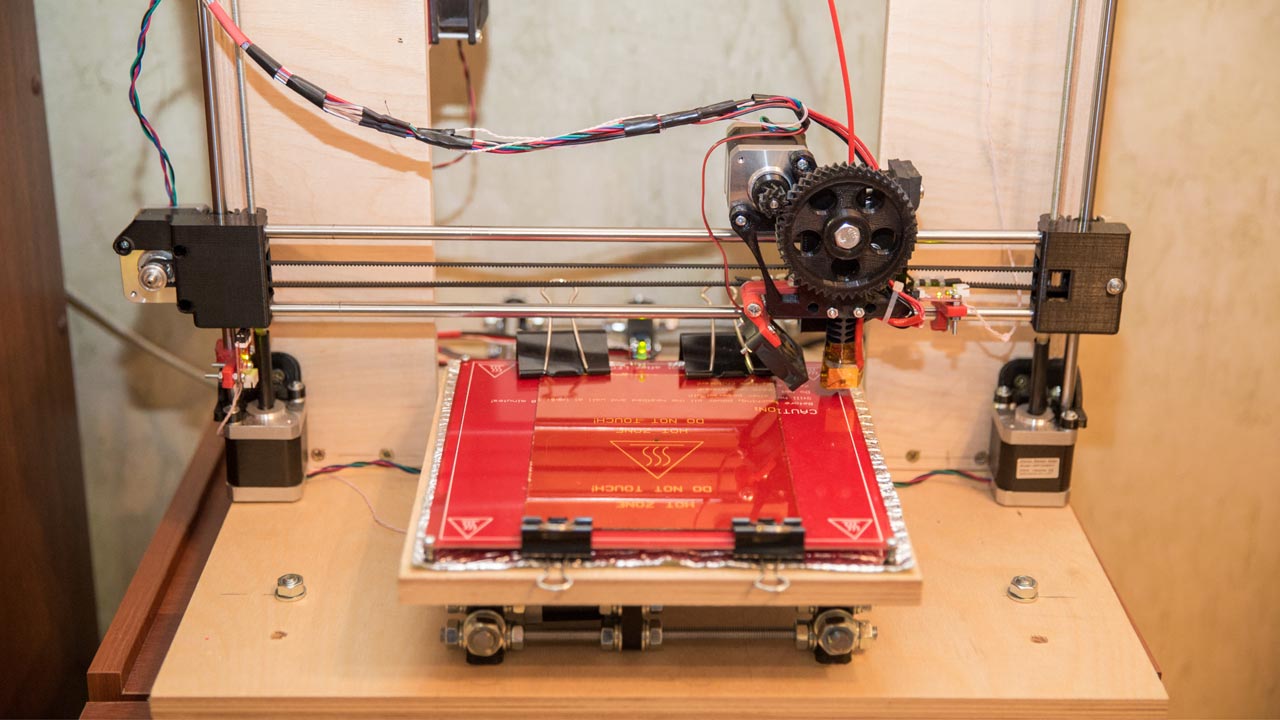

3D modeling involves creating three-dimensional digital representations of objects entirely from scratch using specialized computer software. This process transforms concepts, sketches, or ideas into detailed virtual models through manual construction techniques. Digital artists and engineers build these models by manipulating vertices, edges, and faces within software environments, carefully crafting each element to match their creative vision or technical specifications.

The 3D modeling process begins with conceptual planning, where designers establish the object’s basic structure and proportions. Using professional software, creators manually construct their models by placing and connecting geometric elements. They then apply textures, materials, and precise dimensions to achieve the desired appearance and functionality. This hands-on approach enables designers to create objects that don’t yet exist in the physical world. With unlimited creativity, there are infinite customization options.

What Is 3D Scanning?

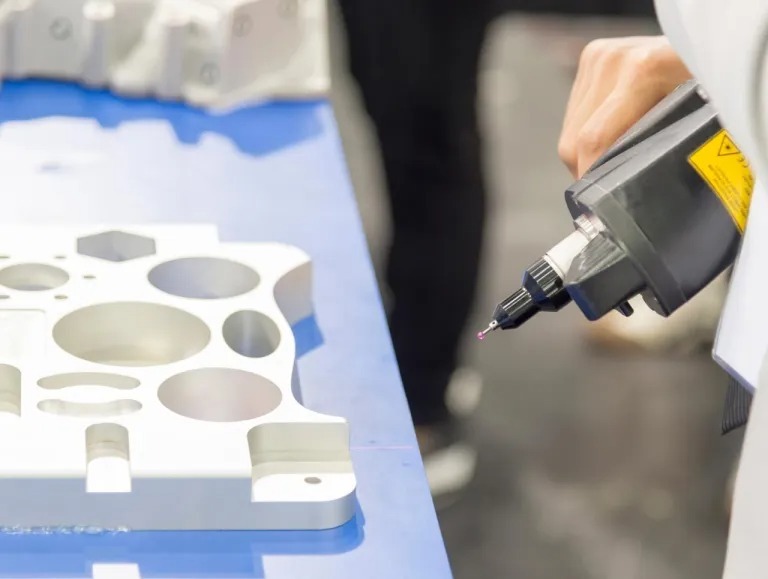

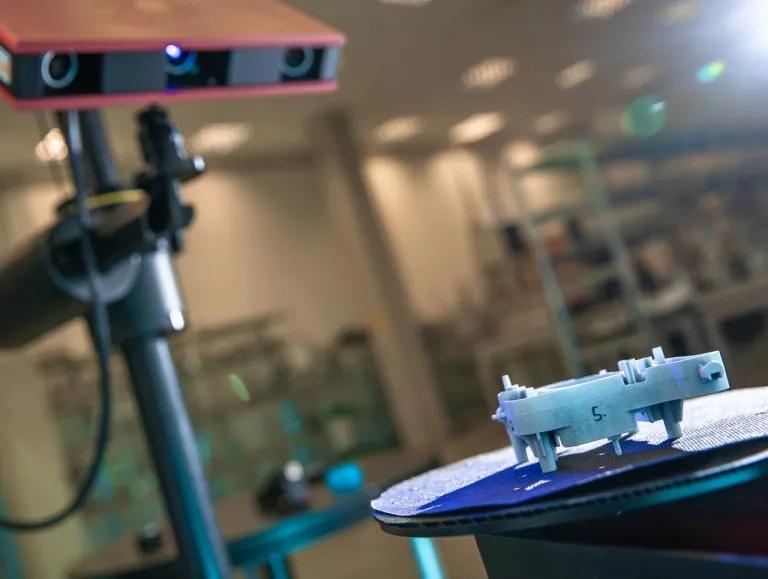

3D scanning takes a fundamentally different approach by digitally capturing the physical dimensions and surface details of existing objects. This technology uses hardware systems to measure and record real-world objects, converting this data into accurate digital replicas. The scanning process eliminates the need for manual model creation by automatically generating 3D representations based on actual physical measurements.

The 3D scanning workflow begins with selecting appropriate scanning equipment. While each device functions differently, they systematically capture thousands of data points from the object’s surface, creating what’s known as a point cloud. Specialized software processes the raw scan data and converts it into a detailed, 3D mesh model that accurately represents the original object’s geometry, dimensions, and surface characteristics.

Tools and Technologies for Each Method

3D modeling relies primarily on software solutions that provide creative and technical design capabilities. Popular applications include Blender for artistic modeling, Autodesk Maya for animation and complex geometry, and SolidWorks for precision engineering applications. These programs offer extensive toolsets for creating unique, tailored models with complete creative control. The flexibility of modeling software allows designers to experiment with shapes, textures, and dimensions without physical constraints.

On the other side of things, 3D scanning requires specialized hardware equipment to capture data effectively. Laser scanners, in particular, use light-based measurement systems to record precise dimensions. Structured light scanners project patterns onto objects to calculate depth and surface details.

Photogrammetry systems work a little differently by using multiple photographs to reconstruct 3D geometry through computational analysis. Supporting software applications process the captured scan data, refining and optimizing the digital replicas for various applications.

Time and Skill Requirements

It should come as no surprise that these methods require a professional’s expertise to achieve desired results. However, 3D modeling typically demands great time investments due to its manual creation process. Building complex models from scratch can take days or weeks, depending on the level of detail and precision required. The modeling process demands artistic creativity or technical design expertise, as creators must understand both the software tools and the principles of three-dimensional design. Successful modelers often combine their creative vision with technical knowledge to produce professional-quality results.

Thanks to the simplicity of the process and its ability to capture object data in minutes or hours rather than days, 3D scanning offers faster turnaround times than 3D modeling. The time savings come from automated data collection, though post-processing and model refinement still require attention.

This doesn’t mean scanning is easy. Operations require insightful interpretation of scan results and the correct equipment. That means operators need a technical understanding of scanning hardware and data processing software. While this learning curve is generally less steep than mastering 3D modeling techniques, it still takes time and dedication.

Applications

In most scenarios, 3D modeling excels in creative and conceptual applications where original designs are required. Animation studios use modeling techniques to create characters and environments for films and video games, building immersive virtual worlds from imagination.

Product development teams rely on 3D modeling for prototyping new inventions, allowing them to visualize and test concepts before physical manufacturing. Architecture and engineering firms use modeling software to design custom structures and mechanical components that meet specific technical requirements.

3D scanning serves applications that require accurate digitization of existing objects. Reverse engineering projects use scanning technology to create digital blueprints of manufactured parts, enabling reproduction and analysis without original design documentation. 3D scanning can even help with anatomical analysis and prosthetics development, creating precise models of patient anatomy for treatment planning. Cultural preservation initiatives use scanning to create permanent digital archives of historical artifacts and archaeological findings.

How Industries Combine Both Methods

Even though 3D modeling and 3D scanning are quite different from each other, many industries leverage both as complementary technologies within their workflows. For example, manufacturing companies often scan existing parts to create accurate base models, then use 3D modeling software to modify designs for improvements or variations. This hybrid approach combines the accuracy of scanning with the creative flexibility of modeling.

Automotive manufacturers scan prototype vehicles to capture precise surface details, then use modeling tools to design aerodynamic modifications or styling changes. The scanned data provides an accurate foundation, while modeling capabilities enable design evolution and optimization. Medical device companies do something similar when they scan anatomical structures to understand patient-specific requirements, then model custom implants or prosthetics that fit perfectly with the scanned anatomy.

Many entertainment studios combine scanning and modeling for realistic character creation. They scan actors’ faces and bodies to capture authentic human features, then use modeling techniques to create costumes, props, and environmental elements. This workflow ensures photorealistic human representation while maintaining creative control over fictional elements. Plus, the integration of both technologies allows for unprecedented realism in digital content creation.

If you want to implement 3D laser scanning and modeling together, Tangent Solutions can help with that. We’re a skilled scanning company that can work all kinds of magic after the fact to help you get the 3D models you’re looking for. Simply reach out if you’d like to learn more about how we can help.