We provide expert 3D scanning Seattle services for projects of all sizes and locations. Paired with the latest 3D laser scanning technology, clients nationwide trust us with their most important engineering projects.

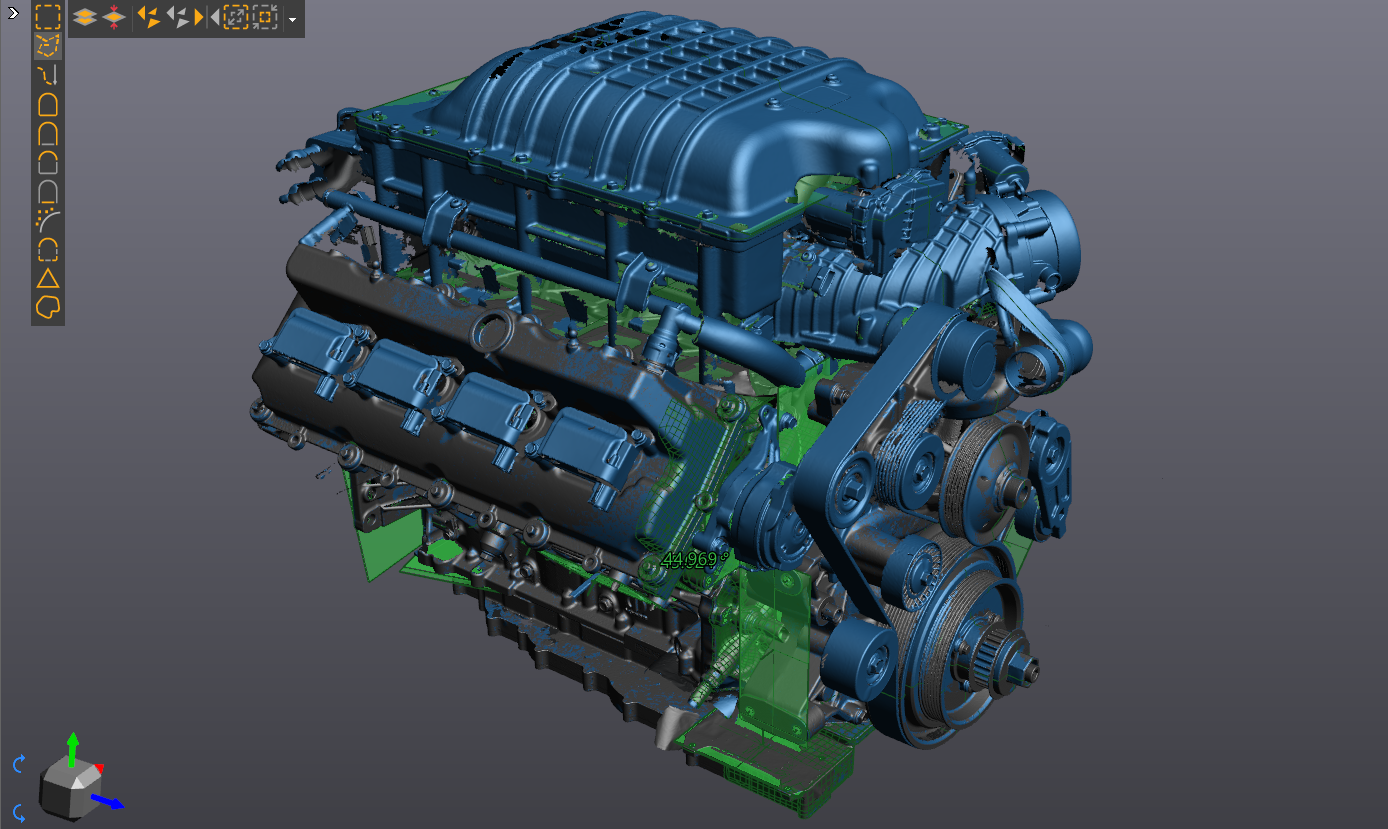

Our team specializes in CAD design and hold knowledge in manufacturing, machining, and aerospace-quality projects. Scan data collected for 3D scanning Seattle is commonly used for reverse engineering, legacy CAD creation, data analysis, and more.

Working with Tangent Solutions gives you access to latest in 3D laser scanning technology paired with CAD design experts.

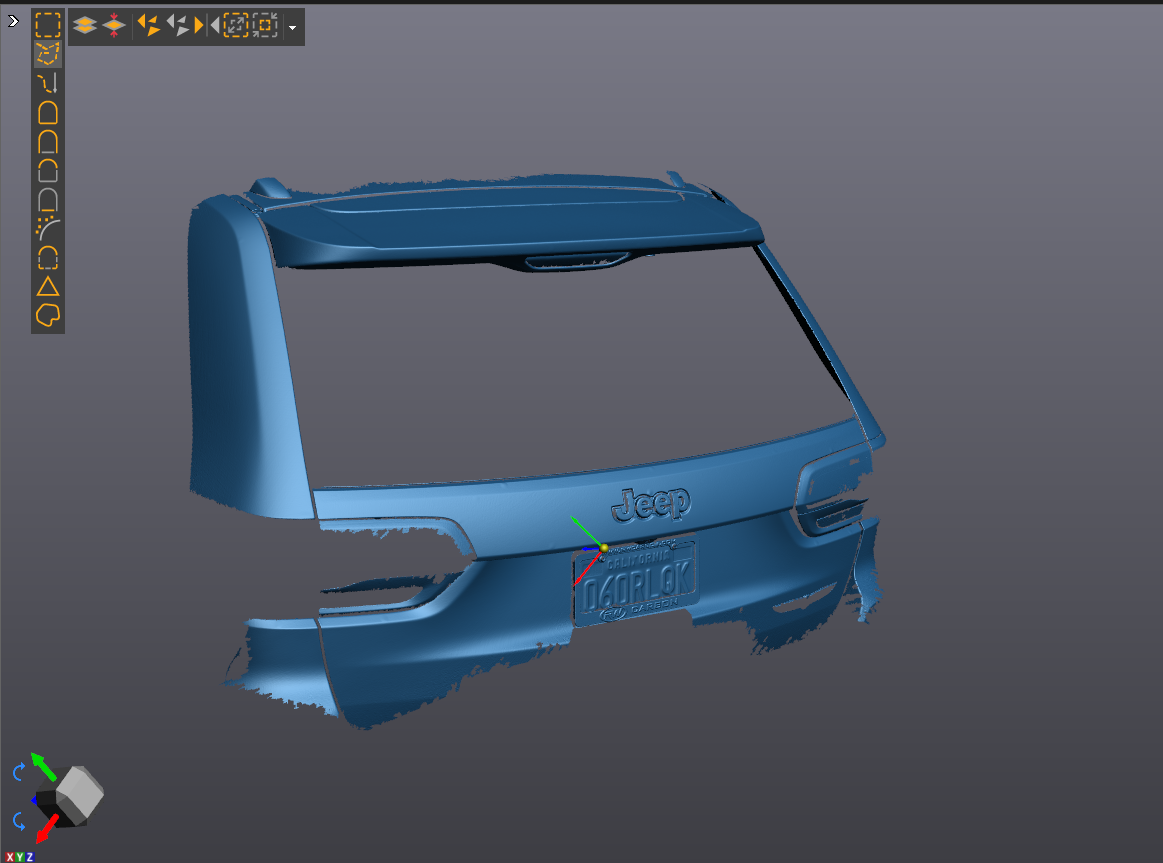

3D scanning Seattle clients now have access to the latest in 3D laser scanning technology. With over 15 years of CAD design knowledge, our team pairs expertise in product development to deliver 3D files ready for manufacturing and more. During 3D scanning, data collected is reverse engineered to produce CAD files up to 0.02mm of precision.

Our team is proud to build relationships with our clients who trust us with their most confidential and urgent projects.

Nationwide, our 3D scanning services provide ultra-precise scan data, no matter the projects size. Technicians can be sent to any remote location or ship in projects to be scanned within our office.

To view samples of commonly delivered data files, click below.

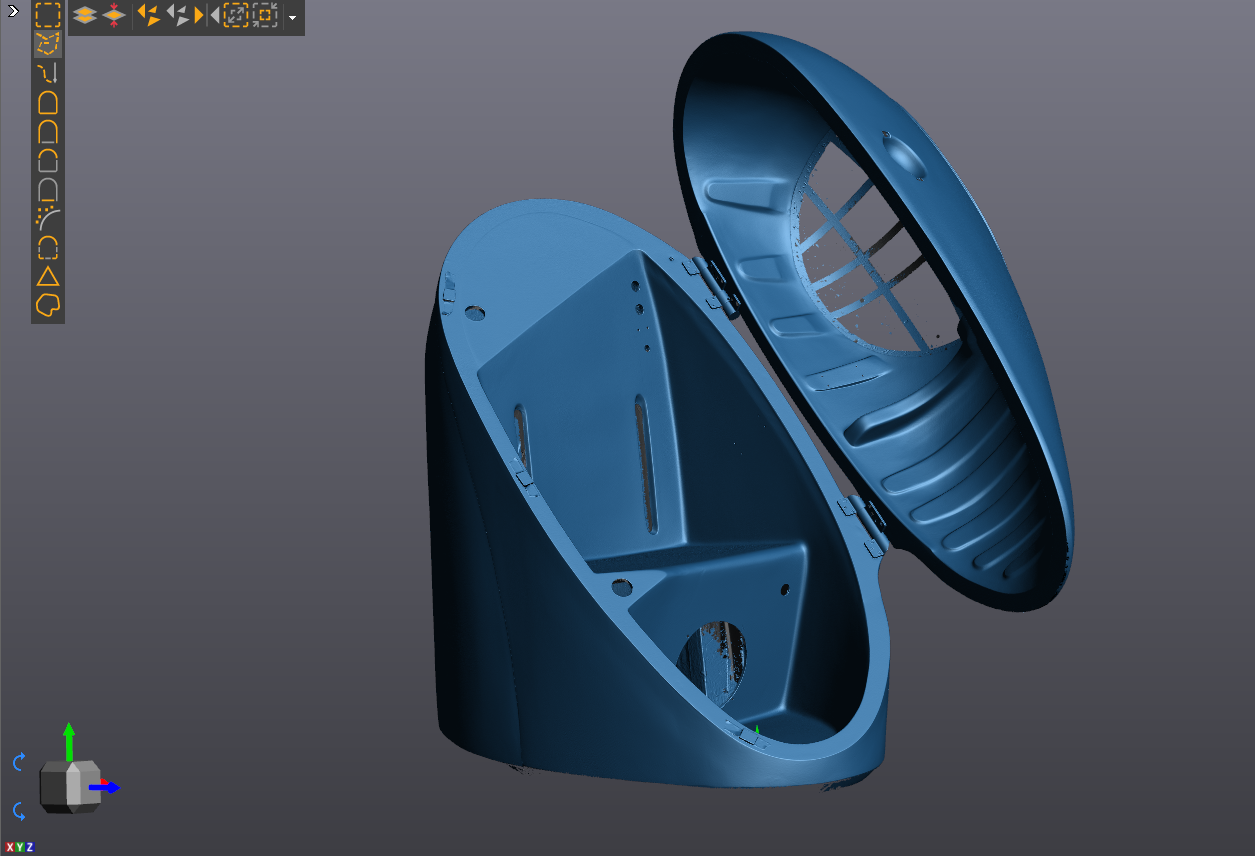

By only scanning what is needed, vital data is exported from the scan and created into individual files. This process speeds up file efficiency and delivery. If CAD file creation is needed, reverse engineering is completed by using scan data as a guide to essentially redraw the project. CAD files can be exported in STEP, IGES, and XT; to name a few common files.

Post processing must be completed in order to export scan data. Initially scan data is created in the scanner's native software. Scans are cleaned up of unneeded data, holes filled, and geometry produced in order to export into STL or OBJ files. Post processing is completed without changing the accuracy of the scan.

If you are looking to manufacture or modify a design, CAD files can be created. By reverse engineering scan data, 3D models are able to uring reverse engineering, files are created using the scan data as a reference. This validates all essential dimensions are included in your CAD files with precision up to 0.02mm.

Our designers are able to optimize scan data to ensure file sizes are never too large to work with. Laser scanning services is not limited by the size of the project. During post processing, important data can be isolated, itemized, and exported individually to ensure a seamless delivery to your team.