In the product development landscape, companies face increasing pressure to deliver faster, more accurate designs without inflating overhead. Maintaining a full in-house CAD department is costly — salaries, benefits, software, hardware, and training can quickly drain resources.

That’s why many organizations now outsource CAD design to trusted engineering partners. Outsourcing allows teams to access experienced CAD professionals on demand, scale resources as needed, and focus internal energy on core innovation rather than production tasks.

In this article, we’ll explore the benefits of outsourcing CAD design, how 3D scanning enhances this workflow, and what to look for in a reliable CAD partner.

The Shift Toward Outsourcing CAD

CAD, Computer-Aided Design, is fundamental to modern product engineering — from early concept sketches to manufacturing-ready models. Yet not every company needs a full-time CAD designer. Outsourcing gives businesses flexibility, expert talent, and access to the latest tools — without the cost of managing a permanent department.

Lower Overhead and Greater Flexibility

Building an in-house CAD team requires long-term investment in workstations, software licenses, and employee benefits. When design needs fluctuate, much of that capacity sits idle.

By outsourcing CAD design, you only pay for the work you need — whether it’s a single product revision or a full design cycle. This flexibility keeps budgets lean while maintaining professional quality.

Access to Experienced Engineers

Outsourced CAD design connects you with engineers who have years of experience across industries — automotive, aerospace, marine, industrial, and consumer products. Their diverse background allows them to anticipate design challenges, recommend manufacturing improvements, and deliver production-ready models.

At Tangent Solutions, our team of mechanical designers and engineers has extensive experience in CAD, 3D scanning, and reverse engineering. That combination of skills enables us to tackle complex design projects quickly and accurately.

Faster Time-to-Market

Speed is one of the greatest advantages of outsourcing. With dedicated CAD professionals handling your modeling workload, you eliminate hiring delays, onboarding time, and software setup.

An experienced CAD partner can accelerate design revisions, quickly implement feedback, and help you reach prototype and production stages much sooner — an advantage that often determines market success.

Up-to-Date Tools and Standards

CAD software evolves rapidly. Maintaining current licenses and training employees on the latest updates adds recurring cost. By outsourcing, you automatically gain access to the most current tools and file standards without worrying about upgrades, renewals, or compatibility issues.

Scalable Resources for Any Project Size

Whether you need one model or hundreds of detailed parts, outsourcing lets you scale up or down seamlessly. You can expand capacity for large production runs or reduce scope after completing a major milestone — without worrying about layoffs, idle staff, or unnecessary overhead.

How 3D Scanning Strengthens the CAD Outsourcing Workflow

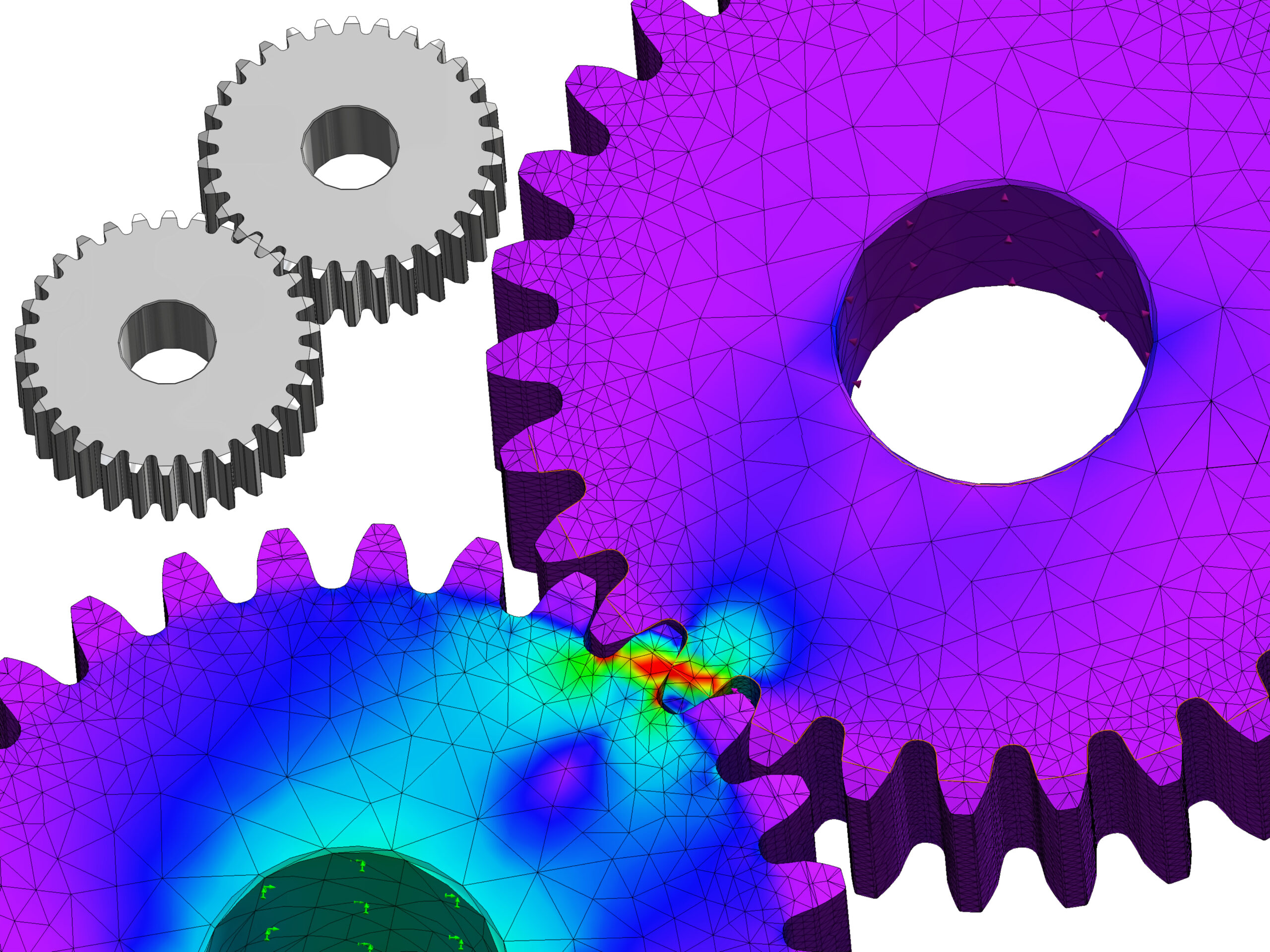

3D scanning has revolutionized the way companies capture and digitize physical objects. When integrated with outsourced CAD services, it creates an end-to-end workflow that transforms real-world parts into editable, manufacturable designs.

From Physical to Digital

3D scanning captures millions of data points on a physical surface, generating a highly accurate 3D mesh or point cloud. This data becomes the foundation for CAD modeling — ensuring the geometry matches real-world dimensions down to fractions of a millimeter.

Whether you’re reproducing legacy parts, reverse-engineering a discontinued component, or validating manufacturing accuracy, combining 3D scanning with outsourced CAD design saves significant time and reduces human error.

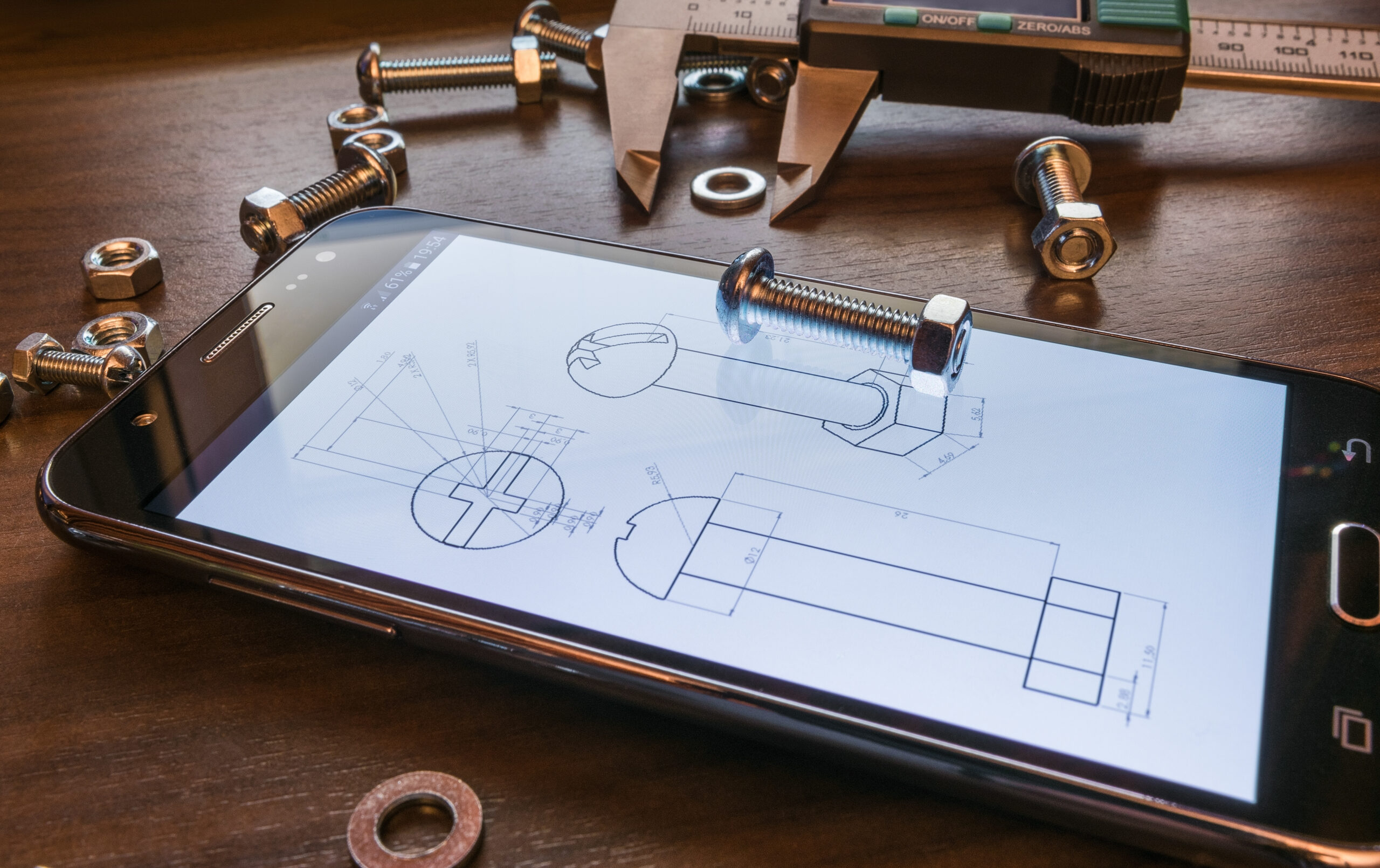

Scan-to-CAD Conversion

Raw scan data cannot be used directly in CAD software; it must first be processed and converted into editable geometry. Tangent Solutions specializes in transforming complex scan meshes into clean, lightweight CAD files that are fully parametric and ready for engineering use.

Our team uses metrology-grade scanners such as the Creaform HandySCAN BLACK Elite, capable of capturing parts with up to 0.025 mm volumetric accuracy. Once processed, we convert those scans into standard formats like STEP, IGES, or XT, ensuring compatibility with your preferred CAD system.

Benefits of Integrating 3D Scanning

- Accuracy – Minimize dimensional errors and eliminate guesswork from manual measurement.

- Speed – Reduce design time by starting with precise digital geometry instead of drawing from scratch.

- Reverse Engineering – Recreate complex parts when no drawings or CAD files exist.

- Quality Verification – Compare manufactured components against original CAD to confirm tolerances.

- Design Optimization – Use real data to improve ergonomics, fitment, and manufacturability.

By merging scanning and CAD expertise, outsourcing becomes a streamlined solution that bridges physical products and digital innovation.

Typical Workflow When You Outsource CAD Design

An effective outsourcing relationship should mirror the discipline and precision of an internal engineering department. Here’s how a typical Tangent Solutions workflow unfolds:

- Initial Consultation

- We define objectives, deliverables, and budget. Whether it’s a redesign, a new concept, or a scan-based model, we establish expectations early.

- Data Gathering

- You may provide physical parts, hand measurements, or existing CAD files. If no geometry exists, we perform a 3D laser scan to generate accurate data.

- Model Development

- Our CAD engineers convert all inputs into parametric models. This includes surface reconstruction, solid modeling, assemblies, and tolerance application per your manufacturing needs.

- Design Review & Iteration

- We present preliminary models for feedback, incorporate revisions, and optimize geometry for production — ensuring functionality, manufacturability, and cost efficiency.

- Final Deliverables

- You receive finalized CAD files, 2D drawings (if required), and any associated mesh or scan data for full traceability.

- Ongoing Support

- Tangent Solutions can remain on retainer or provide ongoing design assistance as your project evolves.

This structured process ensures clarity, accountability, and consistent results from concept to completion.

Optimizing Product Development with Outsourced CAD

Outsourcing isn’t just about cost savings — it’s about speed, quality, and flexibility. When integrated into your overall product lifecycle, it can reshape how you bring products to market.

Faster Prototyping

With access to scalable design capacity, your prototypes can move from idea to production-ready CAD in a fraction of the usual time. Tangent Solutions can deliver rapid design turnarounds, enabling quick iterations and physical 3D-printed prototypes for fit and validation.

Design Refinement and Optimization

Our CAD engineers don’t just replicate geometry — they enhance it. Whether reducing weight, adjusting wall thickness, or improving part fitment, outsourcing design allows for expert analysis and real-world optimization based on proven engineering standards.

Manufacturing-Ready Deliverables

Designing for manufacturability (DFM) is one of the greatest challenges in product development. Tangent Solutions ensures every model reflects feasible tolerances, machining limits, and material specifications — minimizing costly revisions downstream.

Reverse Engineering Legacy Parts

Many clients approach us when they need to reproduce or modify existing components with no digital documentation. Using 3D scanning and reverse engineering, we recreate precise digital twins that can be adjusted, improved, or reproduced as needed.

Seamless Integration with Internal Teams

Outsourcing does not replace your internal engineering capabilities — it enhances them. Tangent Solutions acts as an extension of your team, providing additional bandwidth, specialized knowledge, and clear communication channels that align with your internal processes.

Addressing Common Concerns About Outsourcing

While outsourcing CAD design offers immense advantages, it’s natural to have questions or concerns. Here’s how we address the most common ones:

“Will outsourcing compromise quality?”

Not when managed properly. Our engineers follow strict internal QA protocols for every project. All models undergo geometric checks, tolerance validation, and dimensional verification before delivery.

“How do we communicate and review progress?”

Projects are tracked using structured milestones and progress updates. Clients receive preview renders, model screenshots, or review files at every stage to maintain full visibility.

“Can I request changes after delivery?”

Absolutely. Revisions are part of the process. We work collaboratively until your final deliverables meet exact specifications.

When to Consider Outsourcing CAD Design

You should consider outsourcing when:

- Your in-house team is overloaded or lacks specific CAD expertise.

- You need to process 3D scanning data into usable CAD files.

- You require faster turnaround on prototypes or design revisions.

- You’re managing multiple projects and need temporary design capacity.

- You want to reduce cost while maintaining engineering precision.

By outsourcing, you can redirect internal resources toward project management, marketing, or R&D — leaving technical design execution to a trusted partner.

Choosing the Right CAD Design Partner

Not all CAD outsourcing companies are equal. Look for a partner that provides:

- Industry Experience — Proven results in your sector (automotive, aerospace, consumer products, etc.).

- 3D Scanning Capability — Integration of scan data directly into CAD workflows.

- Engineering Expertise — A team that understands manufacturability, tolerances, and production constraints.

- Clear Communication — Frequent updates, responsive collaboration, and transparent timelines.

- Scalability — The ability to take on small projects or large, ongoing workloads.

- Data Security — Strict confidentiality and controlled file-transfer systems.

At Tangent Solutions, our approach is built around collaboration, precision, and long-term reliability.

The ROI of Outsourcing CAD

The financial and operational returns can be substantial:

- 30–70% reduction in design costs compared to hiring full-time engineers.

- Up to 50% faster project turnaround due to streamlined workflows and scanning integration.

- Improved design accuracy through scan-based data validation.

- Reduced rework and scrap costs by designing for manufacturability from the start.

These measurable benefits make outsourcing one of the most effective ways to optimize your engineering pipeline.

Integrating Outsourcing Into Your Process

To make outsourcing seamless:

- Start with a clearly defined scope, deliverables, and timeline.

- Provide as much data as possible — photos, sketches, physical samples, or scans.

- Establish regular communication checkpoints.

- Review deliverables early to prevent downstream changes.

- Maintain consistent file-naming conventions and documentation.

Tangent Solutions can help set up this process so your outsourcing model becomes a dependable extension of your engineering operations.

Why Partner With Tangent Solutions

Tangent Solutions provides professional CAD design services with Tangent Solutions that integrate 3D scanning, reverse engineering, and manufacturing-ready CAD.

Here’s what sets us apart:

- Mobile 3D Scanning – Using metrology-grade scanners to capture parts and assemblies on-site with unmatched accuracy.

- Experienced CAD Engineers – Skilled in SolidWorks, NX, Catia, and AutoCAD for advanced parametric modeling.

- Reverse Engineering Expertise – Turning scan data into editable, dimensionally controlled CAD for redesign or production.

- Flexible Engagements – Available per-project, on retainer, or as an ongoing design partner.

- Quick Turnaround – Rapid response times, streamlined file delivery, and transparent project tracking.

Whether you need assistance converting scan data, optimizing designs for manufacturing, or developing new products from concept, Tangent Solutions is equipped to deliver results that meet your goals and budget.

Conclusion

As industries evolve, outsourcing CAD design has become a strategic advantage — not a cost-cutting measure. It allows companies to stay agile, reduce overhead, and maintain access to world-class engineering talent.

When combined with 3D scanning, it provides a complete physical-to-digital workflow that speeds up product development, improves precision, and enhances quality control.

If you’re ready to expand your capabilities, streamline your design process, and bring ideas to life faster, contact Tangent Solutions today to learn more about our expert CAD design services with Tangent Solutions.