When we first started Tangent Solutions, our file creation abilities were limited to the size of the project. Customers frequently requested on site 3D scanning for art sculptures, buses, and race vehicles but the platform we used was constricted to a mounting surface.

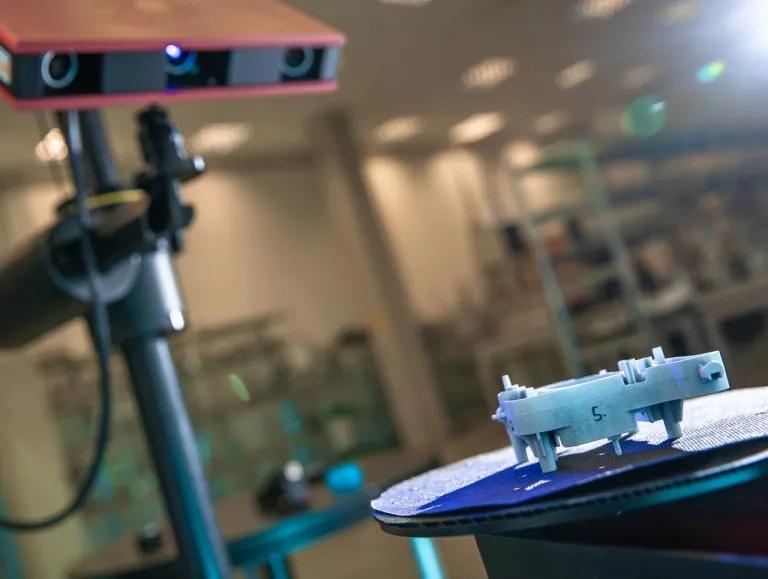

Investing into a completely mobile 3D laser scanner was a game changer. Now, our 3D scanning service is not limited by size or project location. The team is able to arrive on-site and digitize any surface for project objects such as reverse engineering purposes.

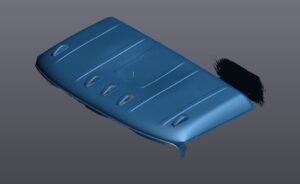

On-site 3D scanning is ideal for clients like Aeroz America LLC, the leading manufacturer of roof-mounted aerodynamic products for the medium duty box truck market. The Aeroz America FuelScoop™, through the reduction of drag, improves fuel economy by a median of 19 ½% while simultaneously reducing carbon emissions by 7-9 tons per truck annually.

Teaming with Tangent allows Aeroz America to provide CAD files of new truck models to their design teams, bringing their newest products to the market faster. CAD files, being universal, permit seamless collaboration between Aeroz international design teams.

In the Field

Our scan technician met Mike Visser, CEO of Aeroz America at two local truck dealerships to perform on-site 3D scanning on three different truck models: the Ford E450, the Peterbilt 536, and the Peterbilt 220.

One of the best features of our mobile 3D laser scanning service is its small footprint. The laser scanner fits in a case that easily fits in the overhead on a commercial airplane and we have our laptop on a secure dolly. All that is needed from the location is access to power.

Our technicians only need enough room to walk around the object to be scanned. For the Aeroz project, a ladder was needed to access the roof of the trucks. The resulting detailed roof scan allows the Aeroz design team to create the perfect fitbetween the cab roof and the underside of the FuelScoop™.

The On-Site 3D Scanning Process

The first step of any 3D scanning service is to prepare the scan area with targets. Targets are adhesive 6-millimeter circles that are placed throughout the project and are what the lasers detect to create a mesh in the computer. This process is called triangulation.

Triangulation is recording of data, usually distance and angle dimensions, and visualizing that data in a point cloud. The point cloud displayed in our native 3D laser scanner’s software is represented in a mesh. This mesh is created instantaneously as the technician scans over the project and also allows for our tech to double che ck his work.

ck his work.

With the use of a ladder, the tech accessed the top of each truck model to scan both the surface of the roof and create data on the distance to the trailer behind.

For this project, we visited two dealerships in order to complete all three scans. This would not be as easy with any other 3D laser scanner and is what sets us apart from other 3D scan service providers.

The versatility of the laser scanner is what makes it ideal for onsite 3D scanning. We use a variety of cord lengths depending on the project size along with a well-stocked supply of targets.

The only limitation is being able to see the software on the computer as the scanning is performed. However, our 3D laser scanner has an alternating light sequence that helps identify if we are too close or too far from the scanning area. It just takes some great hand-eye coordination.

Post Mobile Scan Service

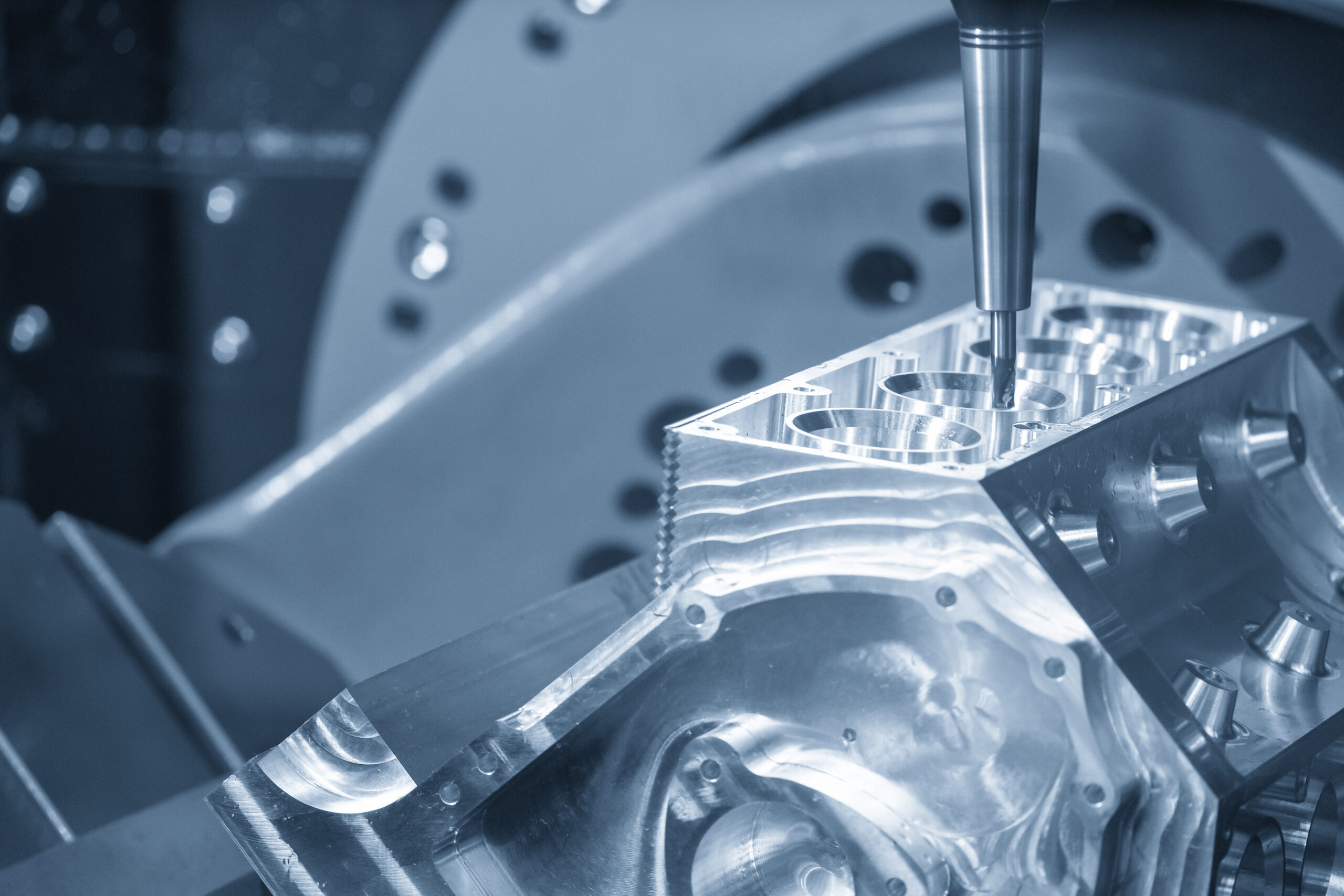

After the on-site 3D scanning of each medium duty truck, the data is downloaded for reverse engineering. Reverse engineering services are required to convert the scanned data into a CAD step file. These files are uploaded providing the Aeroz design teams access anywhere in the world.

Scan data is post processed which includes assigning planes, sketches, and identifying geometry. Our scan technician will perform the cleanup in the same native software and then export it into a mesh file, ready for redrawing.

Drawing CAD files from mesh data is the most time-consuming portion of his project. However, with data that is precise up to 0.02mm, we are able to guarantee the accuracy of the delivered files.

Establishing Partners

Our team at Tangent Solutions has had the pleasure of working with Aeroz America on five different applications to date. Rapid time-to-market is crucial for new product releases. The ability for us to schedule a remote 3D scanning service on short notice was much appreciated by Aeroz America and we look forward to further cementing our relationship in the future.