The automotive industry is no stranger to manufacturing challenges. Rising costs, supply chain interruptions, and growing demand for innovation have left manufacturers, restorers, and hobbyists looking for reliable solutions to keep up in a competitive market.

Luckily, reverse engineering offers a practical way to tackle many of these concerns. By creating detailed replicas or improving upon existing components, reverse engineering has transformed how automotive parts are sourced, maintained, and enhanced. Here are five of the top reasons to reverse engineer your automotive parts.

1. Cost Savings and Efficiency

One of the biggest reasons to reverse engineer automotive parts is the potential for significant cost savings. Recreating components that are either expensive or unavailable can provide affordable and efficient alternatives, making it an ideal solution for various uses in manufacturing and repairs.

Affordable Alternatives

Sourcing original equipment manufacturer parts can often strain budgets, especially when dealing with rare or high-demand components. OEM parts typically carry a premium price tag, and supply can be limited based on the manufacturer’s availability and market dynamics.

Reverse engineering bypasses these constraints by enabling the production of exact replicas or even superior versions of the needed part. Whether it’s for restoring a classic car or fulfilling mass production quotas, this approach helps reduce upfront costs without sacrificing quality.

Preventing Downtime

For industries like automotive manufacturing or racing, delays caused by unavailable parts can have significant financial consequences. Reverse engineering ensures that you can reproduce components quickly, minimizing costly interruptions.

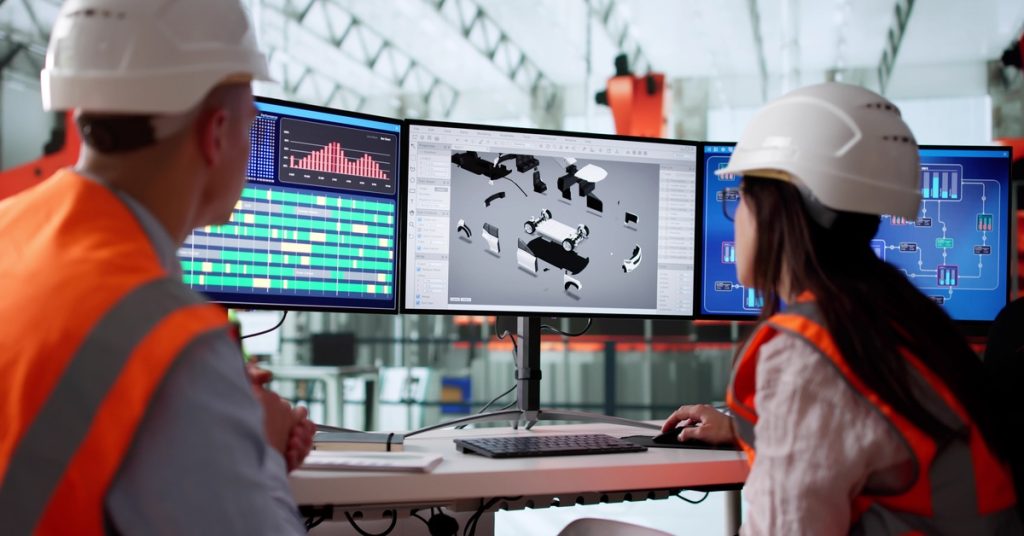

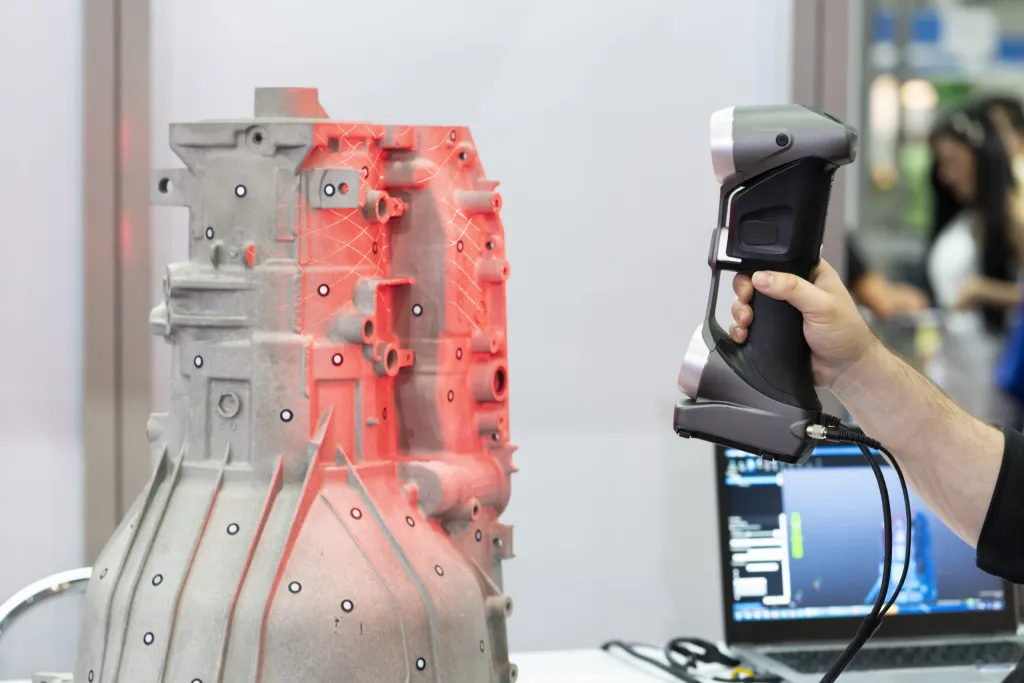

By digitizing part designs through processes like 3D scanning, manufacturers and service providers can accelerate prototyping and reduce lead times. The ability to produce parts on demand keeps operations running smoothly, ensuring that time-sensitive projects stay on track.

2. Solving Supply Chain Issues

With today’s global supply chain facing challenges ranging from component shortages to increased transportation costs, the automotive world has felt the squeeze. Reverse engineering offers a practical solution for those needing automotive parts by reducing dependence on traditional supply chains and enabling manufacturers to recreate critical pieces more directly.

Overcoming Part Obsolescence

One of the most common issues in automotive restoration and manufacturing is part obsolescence. Many vehicles, particularly older models or specialty designs, require components that are no longer in production. Original parts may have been discontinued years or even decades ago, leaving a gap that’s nearly impossible to fill.

Reverse engineering bridges this gap by enabling manufacturers and restorers to recreate parts that are functionally and visually identical to the originals. This is especially important for classic and luxury cars, where maintaining authenticity is paramount.

Reliable Access to Critical Components

Relying on limited suppliers can create bottlenecks in production, especially when those suppliers face disruptions of their own. Reverse engineering eliminates this reliance by digitizing designs and giving manufacturers the ability to develop components in-house or through trusted 3D reverse engineering services. This level of reliability ensures that critical parts are always accessible, helping to stabilize production schedules and mitigate risks associated with supply chain vulnerabilities.

3. Driving Innovation and Customization

Innovation is at the heart of reverse engineering, allowing businesses to not only replicate parts but also introduce enhancements and customizations. Whether you’re looking to improve performance, meet evolving consumer demands, or create entirely new products, reverse engineering serves as a powerful tool for advancing automotive design.

Enhanced Designs

One of the key benefits of reverse engineering is the ability to enhance existing components. Instead of merely replicating an original part, engineers can study its design and identify areas for improvement. For instance, they can re-engineer components to increase strength, reduce weight, or improve material performance. This is particularly relevant in industries like motorsports, where even slight improvements can make a significant difference in performance.

Reverse engineering also allows manufacturers to integrate cutting-edge technologies into traditional designs. They can incorporate modern materials, such as lightweight composites or advanced alloys, into recreated components, delivering superior results without deviating from the original form or function.

Bespoke Solutions

No two projects are the same, and reverse engineering enables the creation of fully customized components tailored to specific needs. This is especially valuable in niche sectors of the automotive market, such as high-performance racing or luxury restorations. Whether developing bespoke parts for a one-off prototype or tailoring components to meet unique specifications, reverse engineering provides the flexibility to create solutions that go beyond standard offerings.

For example, racing teams frequently reverse-engineer parts to fine-tune aerodynamics, enhance engine performance, or improve durability under demanding conditions. Meanwhile, restorers of classic vehicles can create components that match the original aesthetic while introducing subtle updates for improved reliability and safety.

4. Improving Vehicle Performance

For those looking to extract every ounce of capability from their vehicles, reverse engineering opens the door to significant performance enhancements. By studying and modifying existing components, manufacturers and car enthusiasts alike can achieve new levels of efficiency, durability, and functionality.

Performance Optimization

Reverse engineering allows for the fine-tuning of parts to improve how a vehicle functions. Whether it’s tweaking an engine component for better combustion or redesigning a suspension part for smoother handling, the ability to reimagine a vehicle’s inner workings can have noticeable benefits.

These enhancements often address real-world challenges, such as wear and tear, thermal resistance, or energy efficiency. All of this leads to drivers enjoying vehicles that operate better under all conditions.

Competitive Edge in Racing and Manufacturing

For professional and competitive environments, reverse engineering is an invaluable tool. High-stakes settings like motorsport rely on high-performance components that can withstand the extreme conditions of racing while delivering maximum efficiency. Reverse engineering ensures that these parts are optimized for peak performance, allowing teams to maintain a competitive edge.

Similarly, manufacturers looking to differentiate their products in the market can leverage reverse engineering to create innovative solutions that appeal to customers. From proprietary designs to improved functionality, investing in the engineering process can pay dividends in positioning a brand as a leader in quality and performance.

5. A Practical and Scalable Solution

The versatility of reverse engineering makes it suitable for use across a wide range of projects and industries. Whether creating a single high-precision component or scaling up for mass production, the process adapts to the needs of the user. Technologies like 3D scanning and advanced prototyping enable seamless integration into existing workflows, ensuring that reverse engineering remains both practical and scalable. The result? Solutions that fulfill immediate needs while offering long-term benefits across automotive operations.

Reverse engineering isn’t just a stopgap for when things go wrong; it’s an opportunity to rethink how you make parts and how vehicles perform. By investing in this approach, automotive professionals can tackle challenges with confidence while opening the door to creativity and innovation.