Modern product development teams face increasing pressure to deliver innovative solutions faster and more accurately than ever before. Traditional design methods, while reliable, often create bottlenecks that slow down the entire development cycle and increase costs. Advanced manufacturing technologies are reshaping how companies approach product creation, with 3D scanning emerging as a game-changing tool that addresses these challenges head-on.

No matter what type of development you’re doing, there’s a good chance this technology can provide a solution that previously seemed impossible or prohibitively expensive. The following nine applications demonstrate how integrating 3D scanning into your product development process can deliver measurable improvements in efficiency, cost reduction, and product quality.

1. Rapid Prototyping Acceleration

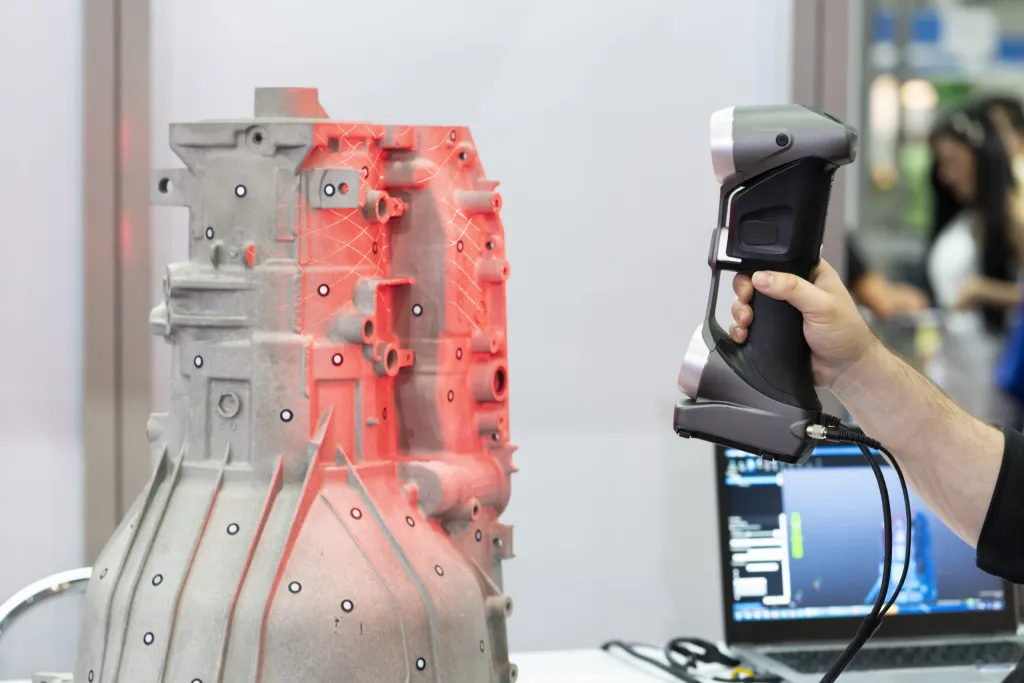

3D scanning revolutionizes the prototyping phase by enabling accelerated design iterations that significantly reduce development timelines. When you scan existing physical objects, the technology captures precise dimensions and creates detailed digital models within hours rather than days or weeks. This rapid digitization allows your design teams to quickly iterate on concepts, test multiple variations, and refine prototypes without the traditional constraints of manual measurement and modeling.

The reverse engineering capabilities of 3D scanning prove particularly valuable when working with legacy products or competitive analysis. Reverse engineering services can scan existing components to create accurate CAD models that serve as starting points for improvements or modifications. This approach eliminates the time-consuming process of recreating designs from scratch, providing a solid foundation for innovation.

2. Enhanced Accuracy and Precision

Precision drives successful product development, and 3D scanning delivers detailed measurements that surpass those of traditional measurement methods. Modern scanning technology captures intricate details and complex geometries with micron-level accuracy, ensuring that your digital models reflect the true characteristics of physical objects. This precision reduces errors in the design phase, which helps provide more confidence in your development decisions.

Fit and tolerance analysis becomes significantly more reliable when you incorporate 3D scanning into your workflows. The technology analyzes how components interact with each other, identifying potential interference issues or gaps before creating physical prototypes. This early detection capability prevents costly redesigns and manufacturing delays that can derail project timelines.

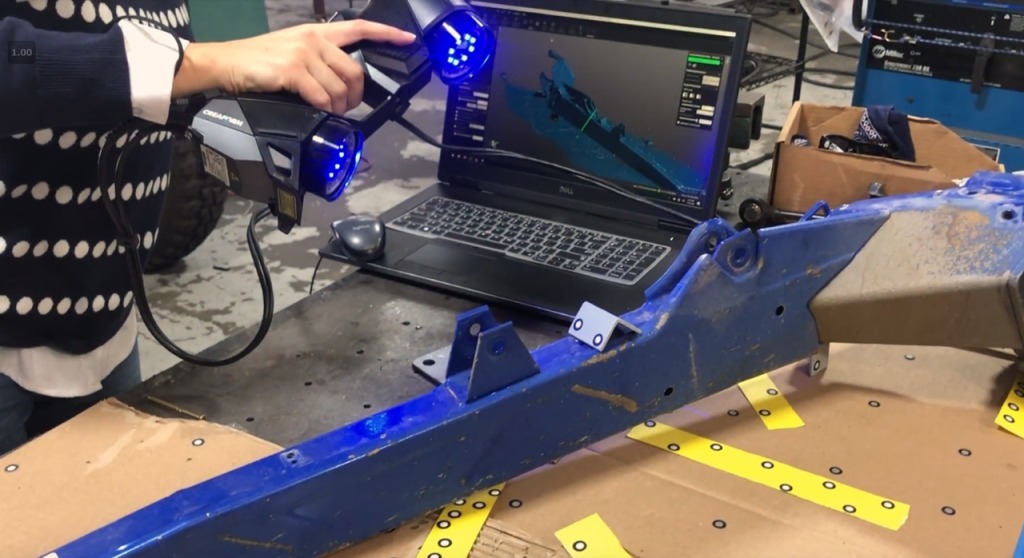

3. Streamlined Quality Control Processes

Quality control represents a critical checkpoint in product development, and 3D scanning transforms how you approach inspection and validation processes. By comparing manufactured parts against original design specifications, scanning technology provides objective, measurable data about product quality and consistency. This comparison process identifies deviations that others might have missed through visual inspections or traditional measurement methods.

Defect detection becomes more sophisticated when you implement 3D scanning protocols. The technology reveals surface irregularities, dimensional variations, and structural issues that could impact product performance or customer satisfaction. Early identification of these problems allows for corrections before mass production, preventing expensive recalls and customer complaints.

4. Customization and Personalization Capabilities

Customer demands for personalized products continue to grow across industries, and 3D scanning enables your team to deliver tailored designs efficiently. The technology captures unique dimensions of individuals or specific applications, allowing you to create custom-fit products such as medical devices, ergonomic tools, or specialized components. This customization capability opens new market opportunities and increases customer satisfaction.

On-demand modifications become feasible when you integrate scanning technology into your design process. Your designers can easily adjust existing models to meet specific customer requirements without having to start from scratch. This flexibility reduces development costs while providing customers with products that precisely match their needs.

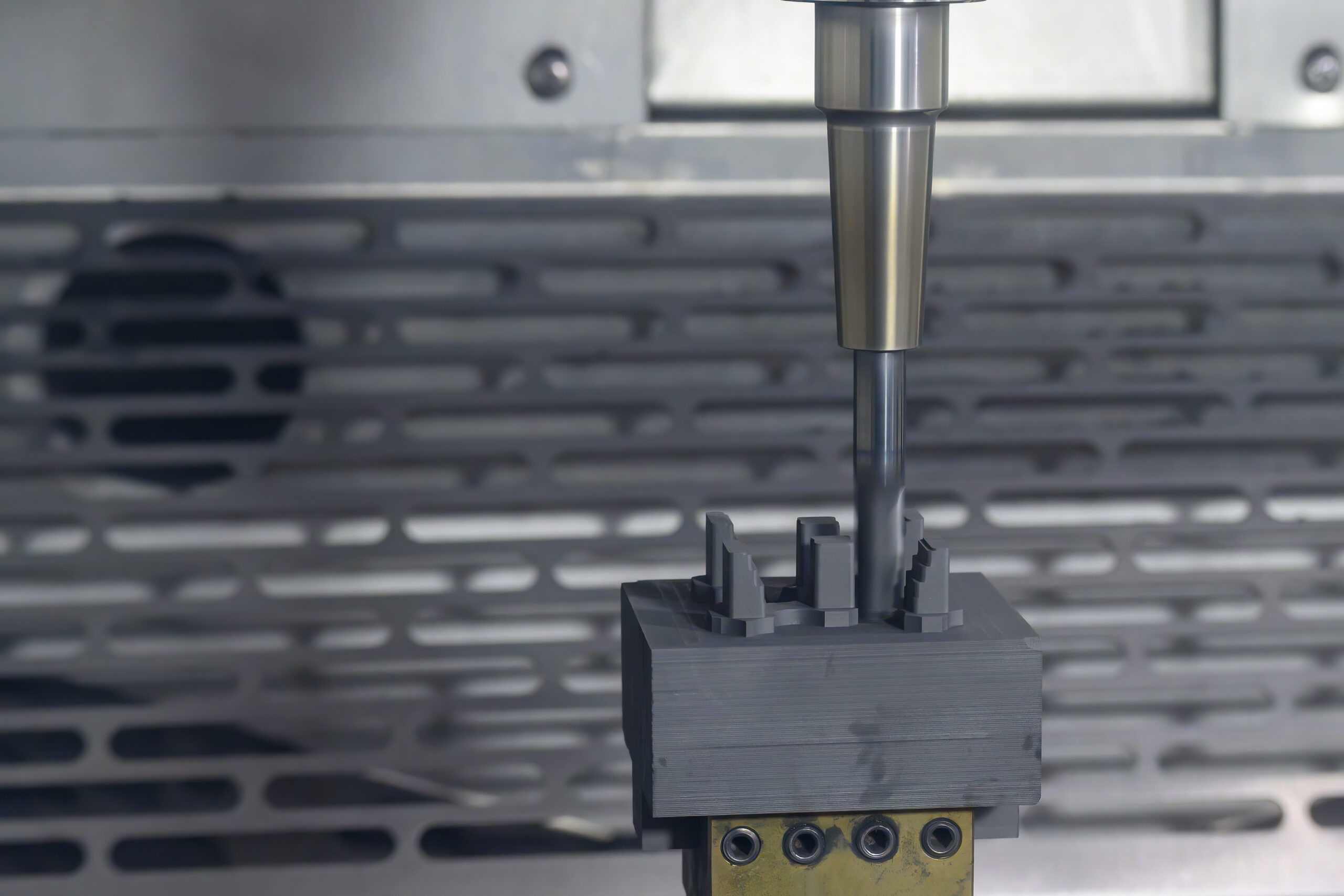

5. Cost and Time Efficiency Improvements

It’s well-known that development efficiency directly impacts your bottom line, but 3D scanning can help with this part of the product development process by reducing both time and material costs throughout the development cycle. By digitizing physical objects, the technology eliminates time-consuming manual measurements and traditional mold-making processes. Your teams can focus on design innovation rather than data collection, accelerating project completion.

Material waste reduction occurs when scanning ensures precise designs before manufacturing begins. Accurate digital models reduce the likelihood of design errors that result in scrapped materials or rework. This precision translates to direct cost savings and improved resource utilization across your development projects.

6. Enhanced Collaboration Opportunities

Global product development teams require practical collaboration tools, and 3D scanning enables digital sharing that facilitates real-time communication. Scanned models can be instantly shared with team members worldwide, allowing for immediate feedback and collaborative design decisions. This connectivity eliminates geographical barriers that traditionally slow down development processes.

Integrating with CAD software creates seamless workflows that directly connect scanning data to your existing design tools. The scanned information seamlessly integrates into your engineering programs, ensuring data integrity and minimizing transfer errors. This process ensures that all team members work with consistent and accurate information throughout development.

7. Historical Preservation and Benchmarking

Archiving designs is something not many people like doing, but it becomes effortless when you implement 3D scanning for historical preservation. The technology creates permanent digital records of physical objects that your teams can reference for future projects or reproduction. This archival capability protects valuable design assets and enhances knowledge transfer between projects and team members.

Benchmarking capabilities enable you to compare new designs with previous models, track improvements, and maintain design consistency. This comparative analysis offers insights into the evolution of design and helps identify successful design elements that should be preserved or enhanced in future iterations.

8. Support for Complex Geometries

Advanced manufacturing techniques require sophisticated design capabilities, and 3D scanning excels at capturing complex geometries that traditional measurement methods cannot handle. This technology excels at accurately representing organic shapes, intricate internal structures, and irregular surfaces, which are essential for modern product designs. This capability is particularly valuable for additive manufacturing applications, where complex geometries provide a competitive advantage.

Topology optimization becomes more effective when you start with accurate scanned data. The detailed geometric information enables a sophisticated analysis of structural efficiency, weight reduction opportunities, and performance optimization. These insights lead to products that perform better while using fewer materials.

9. Integration With AR/VR for Advanced Visualization

Virtual prototyping transforms how you evaluate designs before physical production, and 3D scanning provides the detailed models necessary for compelling AR/VR experiences. You can import scanned objects into virtual environments where your team can interact with designs, test functionality, and identify potential issues. This virtual testing reduces the need for multiple physical prototypes.

Customer feedback collection becomes more engaging when you use AR/VR integration with scanned models. Stakeholders and customers can experience virtual prototypes in realistic environments, providing valuable input early in the development process. This feedback loop ensures that final products meet market expectations while reducing development risks.