3D laser scanning is an innovative technology used to accelerate the creation of engineering CAD files. The files created are ultra-precise, accurate, and speeds up the reverse engineering process, ten-fold.

It seems easy to use, just scan and create a file, right?

Not necessarily.

Investing into the purchase of a 3D laser scanner, plus the software, yearly subscription, and training of employees, leaves most companies outsourcing the service to convert 3D scan to CAD files.

The utilization of 3D scanning technology has become increasingly prominent across various industries, with manufacturing being a key beneficiary. From engineering to the creation of prototypes, 3D scanning services play a pivotal role in transforming physical objects into digital 3D models.

If you are seeking an all-inclusive solution for 3D scanning and CAD modeling, it is crucial to select a reputable company that specializes in 3D scan to CAD services.

In this extensive guide, we will explore the vital aspects to consider when choosing the ideal 3D scan to CAD service provider.

The Fundamentals of 3D Scan to CAD Conversion

Before diving into the selection process, it is important to understand the fundamentals of 3D scanning and how it connects to Computer-Aided Design; CAD, as we continue on.

A 3D scan captures an object’s size and shape by creating a mesh model composed of numerous triangles. These triangles represent the change in shape, distance, and record the measurement down to the thousandth of a millimeter.

However, this mesh model, while visually representing the object, is not suitable for engineering and design purposes. To make it usable for CAD software, the mesh needs to be converted to a working 3D model.

This 3D Scan to CAD file conversion is also referred to as reverse engineering.

What is a CAD File?

A CAD file is a digital representation of a physical object or system created using specialized software. CAD files are used by architects, engineers, designers, and various professionals to design, draft, and model everything from buildings and machinery to intricate products.

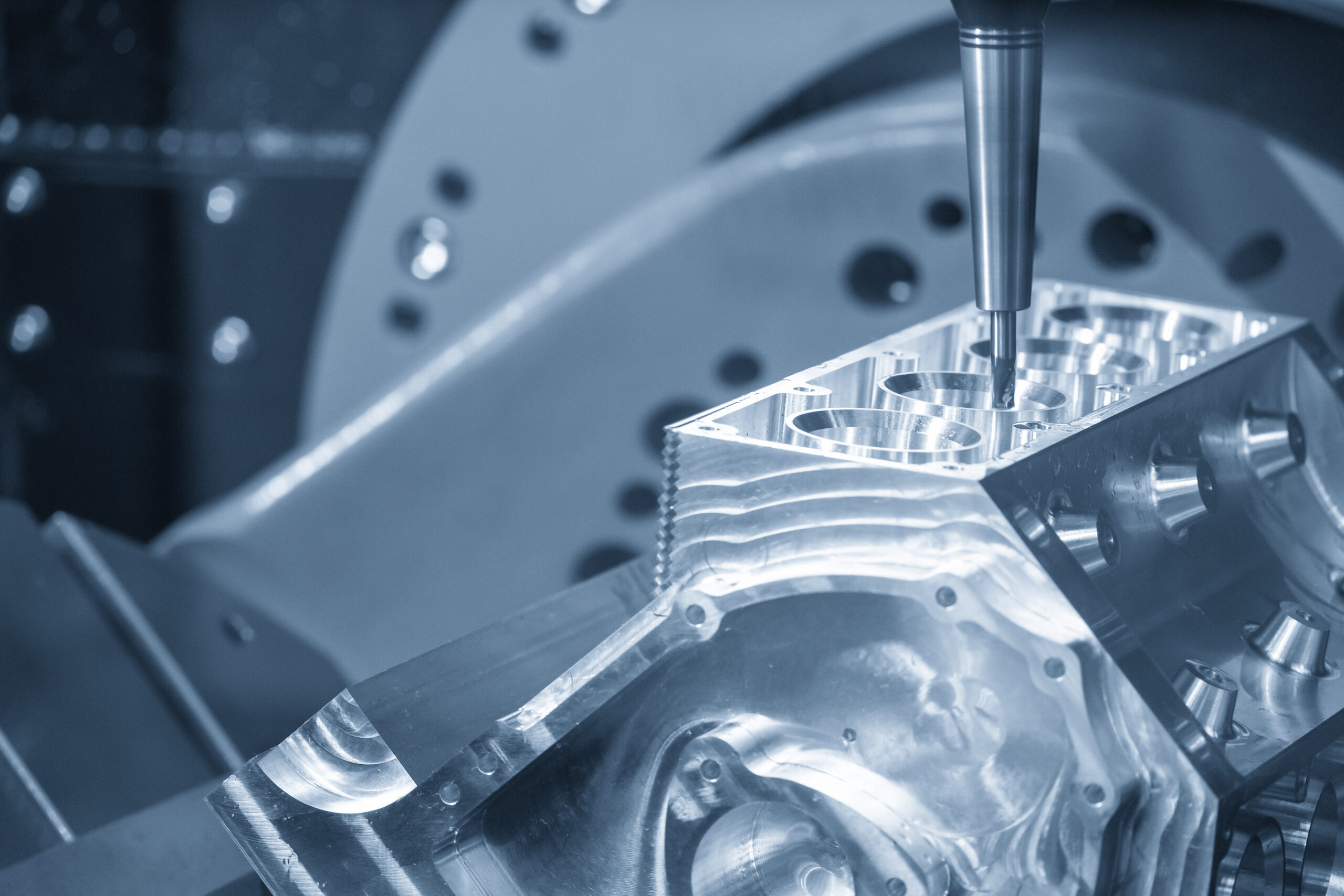

3D laser scanning can be performed on physical parts of any size or material.

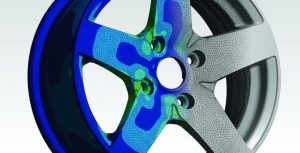

These files provide precise, detailed information about dimensions, shapes, materials, and more, enabling users to visualize, analyze, and refine their designs before production.

Having a digital CAD file ultimately saves time and resources while ensuring accuracy and quality in various industries. If changes are needed, it’s a quick change in CAD software.

How to Convert a 3D Scan to CAD Files

Refining the initial 3D scan mesh involves converting the raw data into a more structured and accurate format that CAD software can readily work with.

This refinement process is often time-consuming and requires specific skills.

Many 3D scanning companies offer mesh refinement as part of their services, taking off the stress of converting the data. This is a valuable time and effort-saving solution for those not well-versed in this aspect.

Once the mesh is refined, it can be imported into CAD software, enabling engineers and designers to work on it. Files are saved in universal format, commonly STEP, IGES, and XT, so that any designer or manufacturer can open the file.

This transition from raw 3D scans to a CAD-compatible format is a crucial step in the process, and it is where a 3D scan to CAD service truly shines.

To learn more about the 3D scan to CAD conversion, read this article.

Key Considerations for Choosing a 3D Scan to CAD Service

Now, let’s delve into the essential factors to consider when selecting the right 3D scan to CAD service provider. Your choice will significantly impact the quality and efficiency of your projects.

Mesh Refinement Expertise

Not all 3D scanning service providers are equally skilled at refining 3D scans.

A critical factor in choosing a service is their ability to take raw scans and turn them into high-quality CAD-ready models. A process called reverse engineering.

Ask to see a copy of work they have submitted before. Many will have a sample folder to review with a variety of CAD files depending upon quality, precision, and results needed for a specific client.

Look for companies with a proven track record in mesh refinement, as this ensures that the data you receive is accurate and suitable for your intended applications.

CAD Proficiency

If you’re in the market for a service to convert 3D scan to CAD models and perform continued CAD design work, it is imperative to ensure that the company has CAD experts on their team.

CAD designers with extensive experience can add tremendous value to your projects. They can not only transform 3D scans into CAD models but also identify and address potential design flaws. This ultimately saves you both time and money.

For example, our company has a team of design engineers who all stem from manufacturing. This ensures the designs we deliver are actually manufacturable and also know what can help a design’s profitability.

Engineering Knowledge

While CAD design expertise is essential, engineering knowledge is equally critical, especially if you aim to bring your products to life.

An ideal 3D scan to CAD service provider should have engineers who can collaborate with you to improve or test functionality, among other essential services.

This additional layer of support ensures that your projects remain grounded in reality and can progress smoothly from the digital realm to the physical world.

The Tangent Solutions Advantage

At Tangent Solutions, we offer a comprehensive 3D scan to CAD service backed by a team of dedicated engineering professionals

Our commitment to delivering exceptional results and providing a seamless journey for our clients sets us apart in the industry.

Core Strengths in Our 3D Scan to CAD Service

Mesh Refinement

We possess the expertise and technology required to refine raw 3D scans, transforming them into CAD-compatible models. This critical step is pivotal in ensuring the accuracy and usability of your 3D scan data.

CAD Proficiency

Our team includes skilled CAD designers who can collaborate with you from project inception to completion.

Whether it’s reverse engineering, identifying design issues, or optimizing designs, our experts are well-equipped to meet your needs.

Engineering Knowledge

To support you in product development, we have engineers on our team that are fully educated on multiple manufacturing processes.

What is your design intent? Anyone can draw in CAD but it takes real engineering experience to understand the end goal of a design.

These insights and skills are invaluable in refining functionality, enhancing product design, and addressing engineering challenges.

We offer flexible access to engineering services, whether on a project-specific basis or through a retainer arrangement.

Conclusion

Choosing the right 3D scan to CAD service is paramount for the success of your projects. With a reliable service provider, you can streamline the transition from 3D scan to CAD models and leverage engineering knowledge.

Tangent Solutions is a trusted partner for all your 3D scanning, reverse engineering, and design needs. Our experienced team is committed to delivering exceptional results, ensuring your projects meet the highest standards of accuracy and quality.

If you are ready to explore the full potential of 3D scan to CAD services, don’t hesitate to get in touch with us today.

We look forward to offering you a comprehensive solution that will drive your projects to success.