3D laser scanning has become an indispensable tool for capturing precise geometric data, reverse engineering complex components, and accelerating digital workflows. Whether you’re digitizing legacy parts, verifying tooling, or preparing models for downstream CAD and manufacturing, understanding the cost structure of 3D scanning is critical for effective project planning.

This guide breaks down the main factors that influence scanning costs, provides an overview of typical project scopes, and explains how to maximize ROI when outsourcing professional scanning services.

Why 3D Laser Scanning Is a Smart Investment

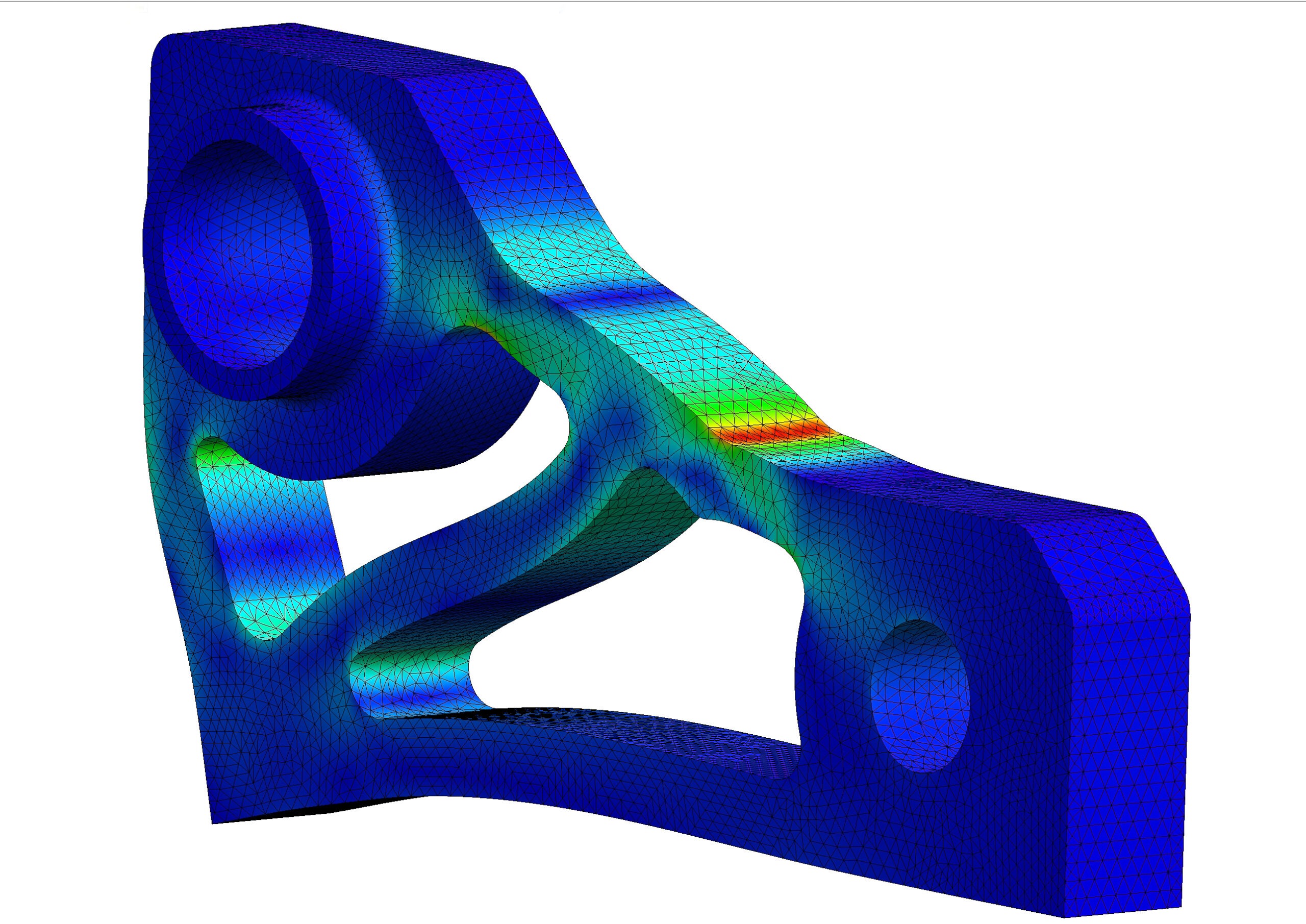

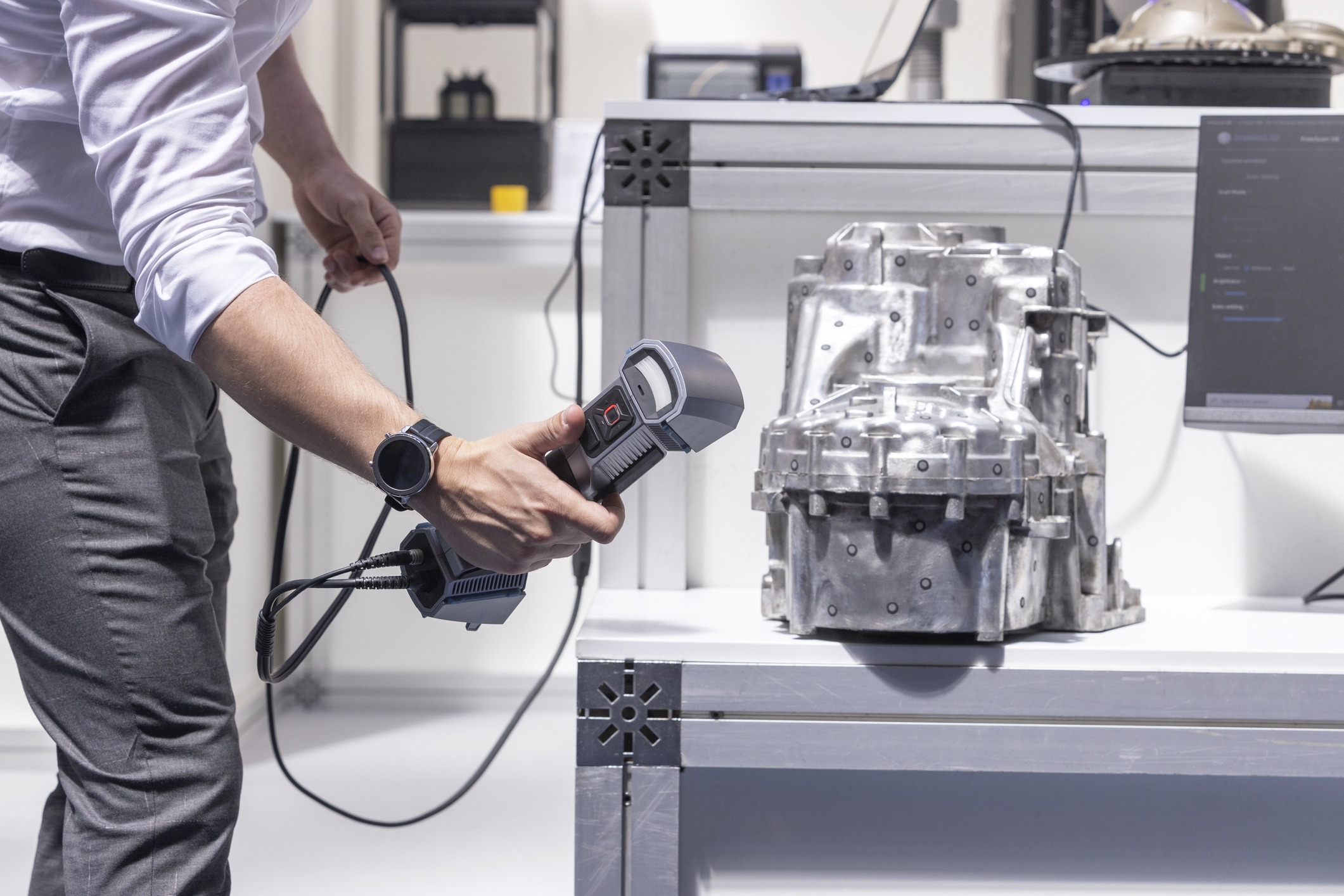

Unlike manual measurement methods or traditional CMM approaches, 3D laser scanning captures millions of data points in seconds — creating a highly accurate digital representation of your part or assembly. That level of precision enables downstream workflows such as reverse engineering, design validation, inspection, or additive manufacturing to proceed more efficiently and with fewer errors.

While the upfront cost of scanning may vary based on scope and complexity, the savings from reduced design iterations, minimized rework, and shorter development cycles often far outweigh the initial investment.

Key Cost Drivers for 3D Laser Scanning

Because every project is unique, there is no universal price for 3D scanning. However, most cost estimates are determined by a combination of the following factors:

1. Part Size and Geometry

Larger components require more scanning time, greater data processing, and larger datasets. Similarly, parts with intricate features — such as threads, cavities, or organic surfaces — require more passes and increased processing time.

2. Surface Finish and Material Type

Highly reflective, transparent, or dark surfaces may require surface preparation (such as applying a temporary scanning spray) to improve data quality. These steps can add time and cost to the project.

3. Accuracy and Resolution Requirements

Higher resolution scans — especially those intended for dimensional inspection or tight-tolerance engineering applications — take longer to capture and process. Projects with ±0.02 mm tolerance requirements will typically cost more than basic form-fitting scans.

4. Project Location and Logistics

In-house scanning (where you ship the part to the service provider) is generally more cost-effective than on-site scanning, which involves travel, setup time, and potentially specialized equipment.

5. Data Processing and Deliverables

The level of post-processing and file output directly impacts total cost. Deliverables can range from raw STL meshes to fully parametric CAD models, reverse-engineered assemblies, and 2D technical drawings. More advanced deliverables require more engineering time and expertise.

Typical Project Scopes

While actual project costs vary widely based on scope, here’s how many organizations categorize their scanning needs:

-

Component-Level Scanning: Small to mid-sized parts digitized for design reference, inspection, or reproduction.

-

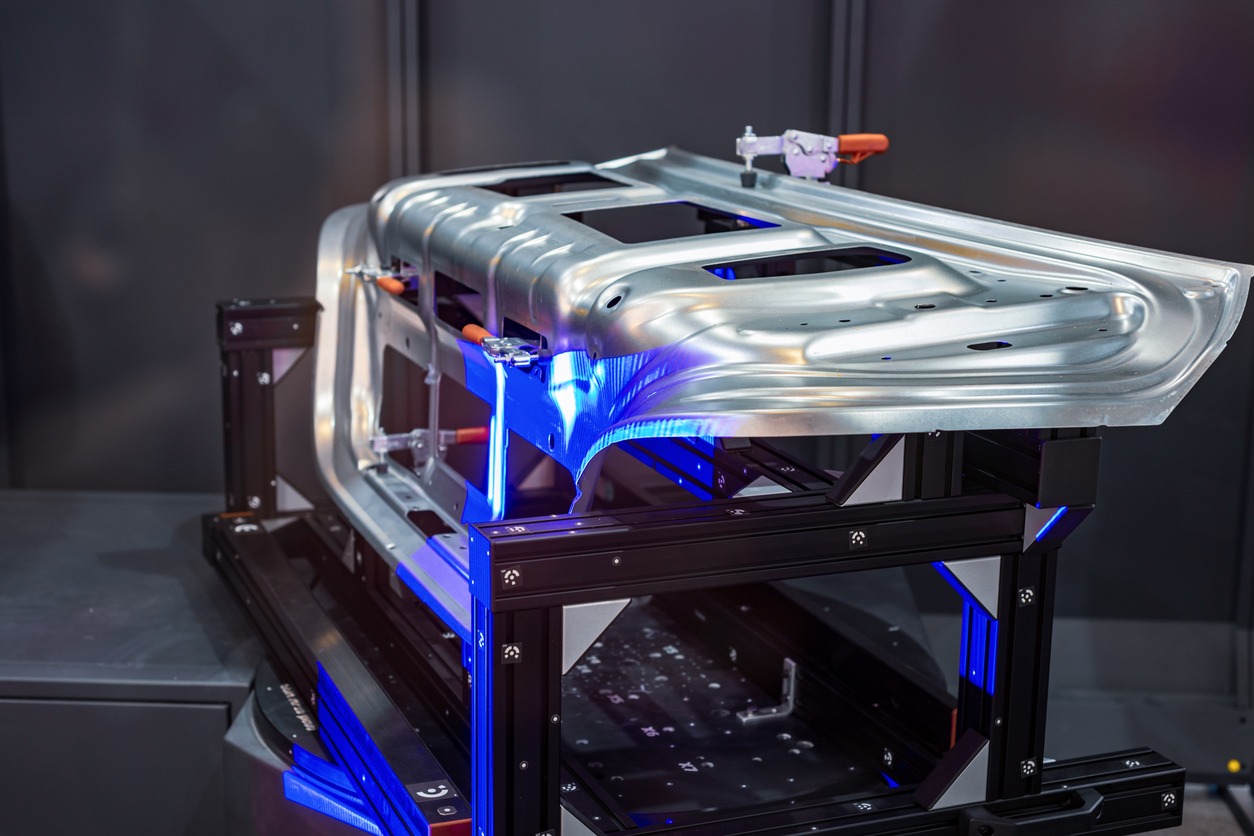

Assembly Scanning: Multiple components or sub-assemblies captured for fitment verification, integration, or reverse engineering.

-

Large-Scale or On-Site Scanning: Full vehicles, structural components, industrial tooling, or facility assets captured on location for modeling or documentation.

Each category involves different scanning techniques, time requirements, and post-processing workflows — which is why an accurate quote always begins with a thorough project review.

Maximizing Value from Your 3D Scanning Project

To make the most of your investment, it’s essential to define project objectives and deliverables clearly before scanning begins. Sharing CAD files, technical drawings, or critical dimensions in advance can help optimize the scanning plan and reduce both time and cost.

Additionally, consider whether you’ll need downstream services such as reverse engineering, CAD modeling, or 2D documentation. Bundling these services with scanning often results in better efficiency and pricing than sourcing them separately.

Work With a Trusted Engineering Partner

Accurate, high-resolution 3D data is the foundation of modern product development — and selecting the right scanning partner is critical to achieving that accuracy while keeping costs predictable. At Tangent Solutions, we combine metrology-grade equipment, proven workflows, and engineering expertise to deliver reliable results across aerospace, automotive, industrial, and consumer product applications.

To explore capabilities, deliverables, and scanning workflows in more detail, visit our page on 3D scanning services and learn how we can support your next project from initial capture to CAD-ready deliverables.

Reach out to us now to schedule a free estimate or give us a call directly, 949-345-0611

Frequently Asked Questions About 3D Laser Scanning Costs

The cost of 3D laser scanning depends on several key variables — including part size, complexity, required accuracy, and deliverable type. Smaller components with basic geometry and standard accuracy requirements are generally more cost-effective, while large, complex parts with tight tolerances or full CAD modeling require more time and engineering resources. Because every project is unique, most service providers offer tailored quotes after reviewing your part specifications and intended use.

A typical scanning project includes three main stages: data capture, post-processing, and deliverables.

Data capture involves scanning your part or assembly with metrology-grade equipment to collect millions of data points. Post-processing aligns, cleans, and optimizes that data into a usable mesh. Deliverables can range from raw STL files to fully parametric CAD models and 2D technical drawings, depending on project requirements.

Additional services like reverse engineering or on-site scanning may also influence final pricing.

Yes — for most engineering and manufacturing teams, 3D scanning delivers a strong return on investment. It reduces time spent on manual measurement, improves design accuracy, accelerates reverse engineering, and minimizes errors in downstream manufacturing. These benefits often outweigh the initial cost by shortening development timelines and reducing rework.

There are several ways to optimize cost without compromising results:

Ship parts in-house rather than requesting on-site scanning. Define deliverables clearly (e.g., raw mesh vs. full CAD model) to avoid unnecessary work. Bundle services like scanning and reverse engineering with the same provider for better pricing. Share technical details in advance, such as drawings or CAD data, to help engineers plan the most efficient scanning workflow.

Project turnaround time varies based on size and complexity. A single small component might be scanned, processed, and delivered within a few business days, while large assemblies or detailed CAD modeling projects can take one to two weeks. Providers typically offer expedited services for projects with tight timelines.