Mining operations have undergone a significant technological transformation over the past decade, with digital innovations reshaping how companies extract, process, and manage resources. Among these advancements, 3D scanning technology has emerged as a game-changing tool that addresses critical challenges across multiple aspects of mining operations.

This comprehensive overview examines how 3D scanning technology benefits the mining industry by delivering measurable results in safety, efficiency, cost management, resource optimization, and equipment maintenance within mining operations. That way, you can determine if your mining company should take advantage of this modern advancement.

Increased Safety in Mining Operations

Safety remains the top priority in all mining operations. While there are already plenty of safeguards in place, 3D scanning processes reduce risks associated with underground and surface mining activities even further. By enabling remote mapping of hazardous areas, this technology minimizes direct worker exposure to dangerous conditions while providing comprehensive data for safety planning.

Underground operations particularly benefit from 3D scanning’s ability to create detailed maps of tunnel systems, caverns, and unstable areas without requiring personnel to physically access these locations. Remote-operated scanners can navigate through potentially dangerous zones, collecting precise dimensional data that helps safety teams identify structural weaknesses and plan appropriate reinforcement strategies. You’ll likely need to hire an external team to handle this kind of work, but it’s better than putting your employees at risk to analyze these unsafe spaces themselves.

3D scans can also detect micro-fractures and stress points in tunnel walls and support structures. These scans reveal structural weaknesses that might not be visible during routine visual inspections, allowing maintenance teams to address potential failures before they pose risks to workers or equipment. The technology also enables real-time monitoring of ground movement and subsidence, providing early warning systems for potentially catastrophic events.

Enhanced Efficiency Through Precision Data

Accurate geospatial data forms the foundation of efficient mining operations, and 3D scanning delivers unprecedented precision in mapping and measurement capabilities. This technology streamlines mine planning by creating comprehensive digital models that integrate seamlessly with existing mine management software systems.

Digital mine models generated through 3D scanning enable engineers to optimize excavation patterns, plan equipment routes, and design processing workflows with millimeter-level accuracy. This precision reduces errors in drilling operations, ensures proper blast hole placement, and minimizes over-excavation that leads to wasted resources.

Mine expansion projects particularly benefit from this technology’s precision. When expanding existing operations, 3D scans provide the exact measurements of current infrastructure, allowing engineers to design expansions that maximize space utilization while maintaining operational continuity. This approach has demonstrated significant improvements in project timelines and resource allocation accuracy across multiple mining operations.

Cost Savings and Downtime Reduction

The financial impact of integrating 3D scanning into mining workflows extends far beyond the initial technology investment. By identifying operational inefficiencies early, this technology helps reduce material waste and optimize resource allocation throughout the extraction process.

3D scanning processes make this possible by enabling predictive maintenance strategies that significantly reduce unplanned downtime. Regular scanning of critical equipment components reveals wear patterns and potential failure points before they cause operational disruptions. This proactive approach allows maintenance teams to schedule repairs during planned downtime periods, avoiding costly emergency shutdowns.

Mining operations that utilize this technology typically notice substantial cost savings after implementing it into their regular processes, such as conveyor system monitoring. In a case like this, companies can use the data this technology creates to identify inefficiencies in material flow. When corrected, businesses will be able to increase throughput without additional equipment investment.

Better Resource Management and Sustainability

Resource optimization and environmental stewardship increasingly drive mining industry decisions, and 3D scanning technology improves things here by supporting both objectives through precise mapping and monitoring capabilities. That’s because this technology enables more sustainable mining practices by maximizing resource extraction while minimizing environmental impact.

Accurate mapping of ore deposits allows mining engineers to design extraction patterns that optimize yield while minimizing waste rock generation. 3D scanning creates detailed geological models that identify high-grade zones and help plan selective mining approaches that reduce processing requirements and environmental disturbances.

Stockpile management represents another significant application area. Volumetric analysis through 3D scanning provides exact measurements of inventory levels, enabling better planning for processing schedules and transportation logistics. This precision eliminates the guesswork traditionally associated with stockpile estimation and supports more accurate financial reporting.

For example, a mining operation could use 3D scanning for deposit mapping and extraction planning. This technology can then help identify high-grade zones, potentially increasing yield and reducing waste. This dual benefit significantly improves the operation’s environmental footprint while enhancing profitability.

Improved Equipment Monitoring and Maintenance

Mining equipment represents substantial capital investments for companies, and 3D scanning technology can help extend equipment lifecycles through comprehensive monitoring and maintenance support. This is thanks to this technology’s ability to enable detailed condition assessments that inform maintenance decisions and support equipment optimization strategies.

Regular scanning of critical mining components reveals wear patterns that indicate when replacements or repairs become necessary. This data-driven approach to maintenance scheduling reduces both premature part replacements and unexpected failures that cause operational disruptions.

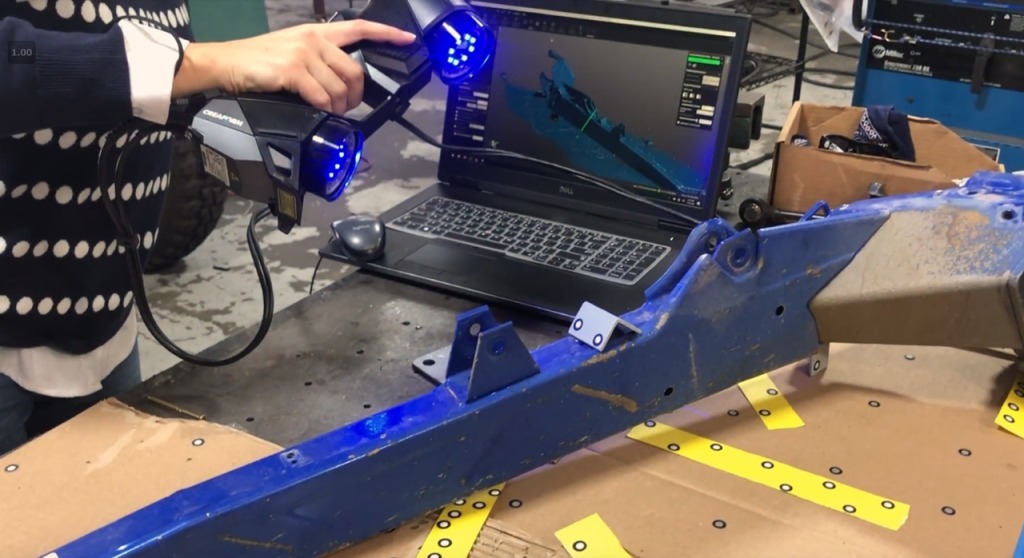

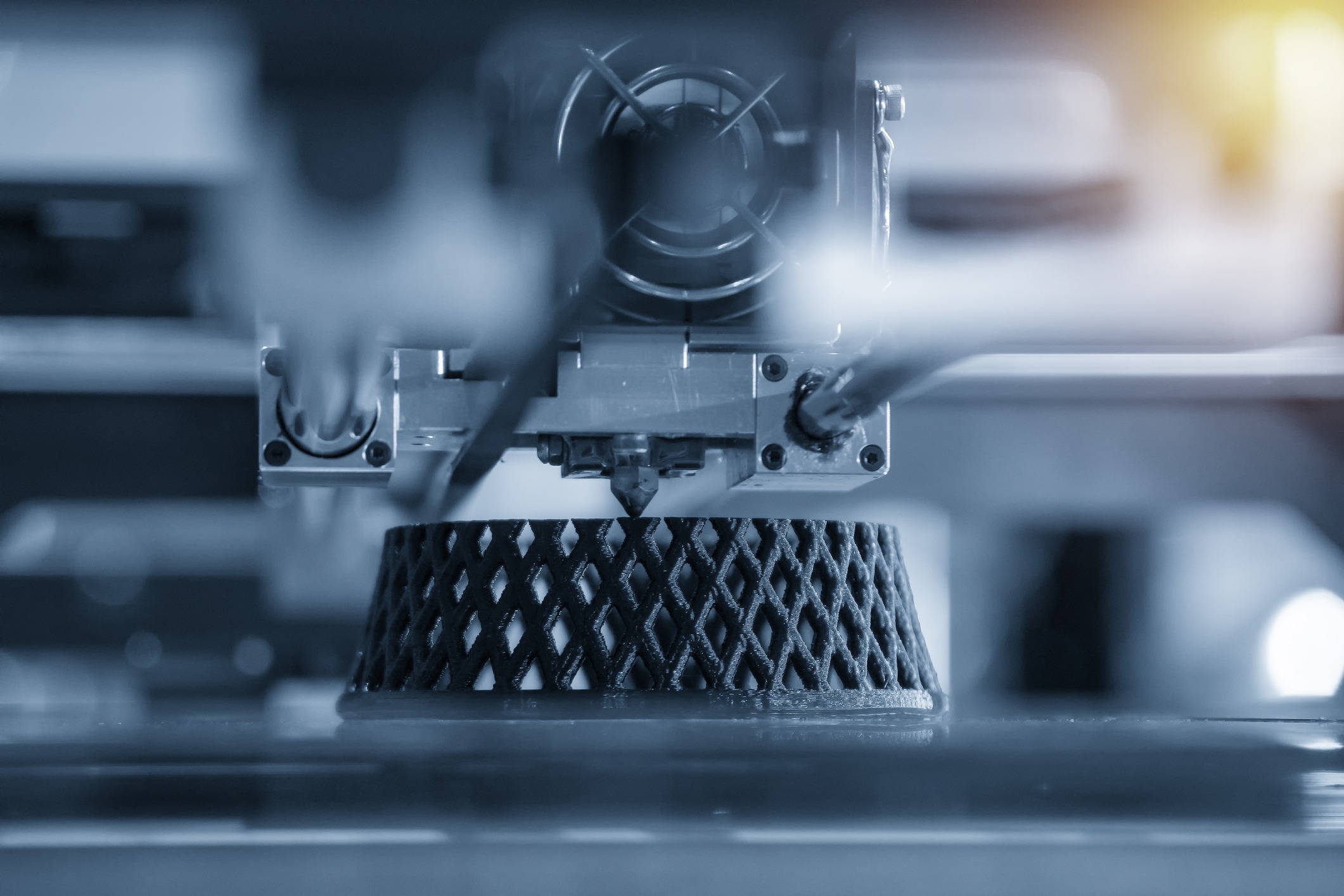

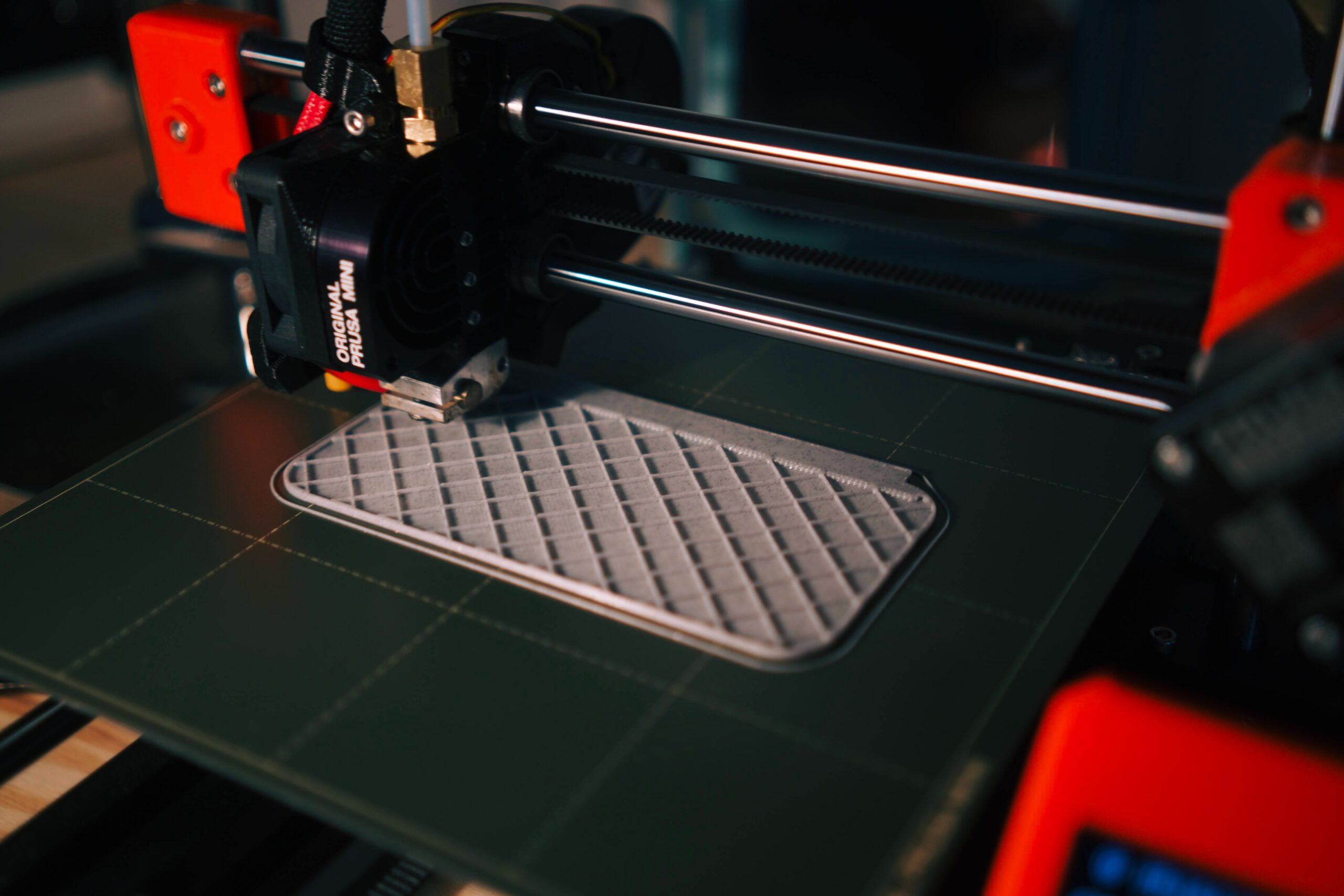

3D scanning also supports reverse engineering applications for older equipment where original parts may no longer be available. By creating precise digital models of worn components, maintenance teams can manufacture replacement parts that match original specifications, extending equipment lifespan and reducing replacement costs.

Practical applications include monitoring crusher wear patterns to optimize liner replacement scheduling, scanning conveyor structures to identify stress concentrations, and creating digital archives of critical components for future manufacturing reference. With this kind of information in hand, it’ll be much easier to make decisions about older or worn-out equipment.

How Tangent Solutions Can Help

As you can see, the use of 3D technology within the mining industry ranges from massive environmental scans to smaller equipment-based ones. Due to this fluctuation, handling everything in-house might not be a possibility, especially since these scans require specialized equipment and personnel with expertise to handle the data.

If the idea of having all of your equipment scanned for digital use sounds like something that would greatly benefit your business, then Tangent Solutions is here to help. We can scan the equipment for you, then provide 3D CAD services to turn these scans into usable data. With this kind of information in hand, you’ll be able to monitor and enhance your mining equipment like never before.