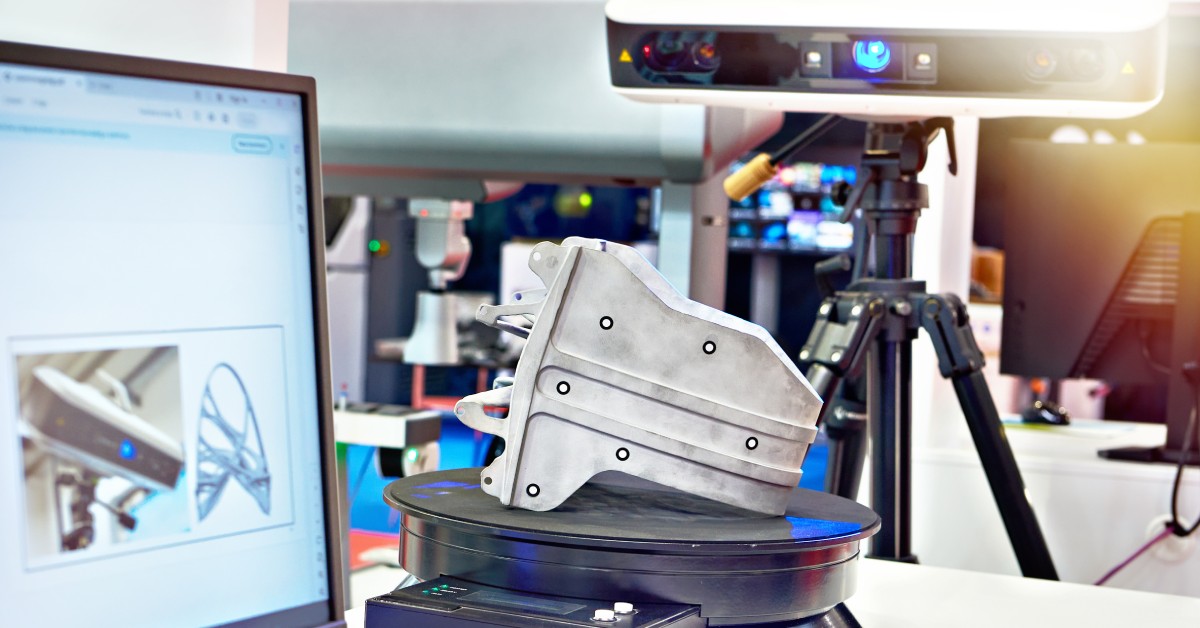

3D laser scanning is a revolutionary technology that captures the shape of physical objects using laser light. By creating a “point cloud” of data from the surface of an object, this process generates a precise digital 3D model.

Because of this, 3D laser scanning has the capability to transform how we design, inspect, and innovate across numerous sectors, from ensuring the structural integrity of a skyscraper to preserving priceless historical artifacts. To appreciate its current impact, it’s helpful to understand its journey from a theoretical concept to the powerful tool it is today. Here’s a deep look at the history of 3D laser scanning and how it’s evolved over time.

The Origins of 3D Laser Scanning

The foundation of 3D laser scanning lies in the invention of the laser itself. While the theoretical groundwork was laid by physicists in the mid-20th century, it was Theodore Maiman’s successful demonstration of the first functioning laser in 1960 that marked a turning point. This breakthrough opened up a new world of possibilities for measurement and mapping.

During the 1960s and 1970s, scientists and engineers began exploring the laser’s potential for precise distance measurement. Early adopters, like NASA, were instrumental in pioneering these applications. They used laser-based systems for space exploration tasks, such as mapping the moon’s surface during the Apollo missions. These initial uses, while not 3D scanning as we know it today, were crucial first steps, proving that we could use focused light to collect highly accurate spatial data.

The Birth of 3D Laser Scanning

The 1980s saw the emergence of the first true 3D laser scanners. These early devices were a significant leap forward, designed to collect data point-by-point to build a three-dimensional representation of an object. Users would direct a laser beam at an object, allowing a sensor to measure the distance and angle to create a single coordinate in 3D space. By repeating this process thousands of times, a complete digital model could be slowly pieced together.

However, these pioneering scanners were far from perfect. They were plagued by significant technological limitations, including their massive size, exorbitant cost, and incredibly slow processing speeds. A single scan could take hours or even days to complete and process, making the technology impractical for many applications.

Despite these challenges, industries that required high precision and had substantial budgets, such as automotive and aerospace, became early champions. They used 3D scanning for quality control, reverse engineering, and prototyping, paving the way for future advancements.

The 1990s: A Decade of Innovation

The 1990s marked a period of rapid innovation in 3D laser scanning. Significant advancements in hardware led to the development of scanners that were more portable, faster, and more accurate. This era saw the rise of two primary scanning technologies still used today. One was triangulation-based scanners, which use geometry to calculate dimensions for high-accuracy, short-range applications. The other was time-of-flight scanners, which measure the time it takes for a laser pulse to travel to an object and back, ideal for large-scale scanning.

On the software side, the development of sophisticated Computer-Aided Design (CAD) programs was a game-changer. For the first time, the massive point cloud data generated by scanners could be effectively processed, cleaned, and converted into usable 3D models. This synergy between hardware and software made 3D scanning a more viable tool, leading to wider adoption. Industries such as architecture began using it for as-built documentation, while archaeologists and forensic experts found it invaluable for preserving and analyzing delicate sites and evidence without physical contact.

The 2000s: The Digital Revolution

The new millennium brought a digital revolution that catapulted 3D laser scanning into new realms. Moore’s Law held true, and the exponential growth in computing power made it possible to process vast amounts of 3D data faster than ever. This was also the decade when LiDAR (Light Detection and Ranging) technology, which had been under development for some time, became more widely known and integrated into commercial scanning systems.

The impact was felt far and wide. The entertainment industry embraced 3D scanning for creating breathtaking CGI in films and more realistic environments in video games. This allowed for a new level of visual fidelity and immersion. Simultaneously, the technology began to shrink. The emergence of handheld and drone-mounted scanners offered unprecedented mobility and flexibility, allowing operators to capture data in complex or hard-to-reach locations. This miniaturization was key to expanding 3D scanning applications beyond industrial settings.

The 2010s: Mainstream Adoption

By the 2010s, what was once a niche, expensive technology started to become mainstream. The cost of 3D laser scanners dropped significantly, making them accessible not just to large corporations but also to small businesses, researchers, and even individuals. This democratization of the technology sparked a wave of creativity and innovation.

Another major development was the integration with cloud computing. Cloud-based platforms emerged, offering scalable solutions for storing, sharing, and collaborating on massive 3D data files. Teams from different parts of the world could now work together on the same dataset seamlessly.

This decade saw 3D scanning become a cornerstone of many real-world applications. It became integral to the 3D printing workflow, enabling the creation of custom medical implants and prosthetics. It also played a vital role in cultural heritage preservation, such as the digital archiving of historical monuments at risk of destruction.

Current Trends and Future Directions

Since the history of 3D laser scanning doesn’t go back too far, it shouldn’t come as a shock that it continues to evolve at a rapid pace today. Many of these advancements are driven by advancements in artificial intelligence and machine learning.

Teams use AI algorithms to automate the data processing workflow, automatically identifying and classifying objects within a point cloud, which dramatically reduces manual effort and increases efficiency. Real-time scanning is another exciting frontier, with new systems capable of capturing and processing 3D data almost instantaneously. This opens up possibilities for live feedback during construction, manufacturing, and even surgical procedures.

Looking ahead, the potential applications for 3D laser scanning are virtually limitless. The technology is poised to play a critical role in the development of autonomous vehicles, providing the “eyes” for cars to navigate their environment safely. In robotics, it will enable machines to interact with the physical world with greater awareness and precision. From personalized manufacturing to augmented reality, 3D laser scanning is set to continue its trajectory as one of the most transformative technologies of our time.

If you want to take advantage of this technology but don’t want to invest the money needed to purchase this kind of equipment on your own, Tangent Solutions is here to help. We’re a full-service CAD design company offering a range of 3D scanning services. With our help, you’ll be able to take your business to the next level.