3D laser scanning is a cutting-edge technology that has revolutionized industries like construction, engineering, architecture, and manufacturing. It allows for highly accurate and detailed digital representations of real-world objects and environments.

If you are considering using it for a project, how much does 3D laser scanning cost?

It’s crucial to understand the cost breakdown and what to expect in terms of pricing. In this comprehensive guide, we’ll delve into the factors that influence 3D laser scanning cost, helping you make informed decisions for your specific needs.

Understanding the Basics of 3D Laser Scanning

Before we break down the costs, let’s briefly review what 3D laser scanning entails.

What is 3D Laser Scanning?

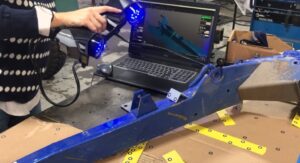

3D laser scanning is a method that employs laser beams to meticulously record the three-dimensional structure and characteristics of objects, producing a digital representation in 3D files.

This point cloud can then be used to generate accurate 3D models, both for conceptual and manufacturing purposes, of the scanned object. This is commonly delivered in STL, OBJ, STEP, or IGES formats.

Common Applications of 3D Laser Scanning

3D laser scanning is commonly used for applications such as creating 3D models for product development, data verification, quality control in manufacturing, and much more.

Here are industries and the way 3D laser scanning is used within:

Architectural Documentation:

3D laser scanning is invaluable for architectural documentation, enabling the accurate capture of as-built conditions, which serves as a fundamental step in renovation or restoration projects.

This technology aids architects and preservationists in preserving the original design and historical significance of buildings.

Engineering:

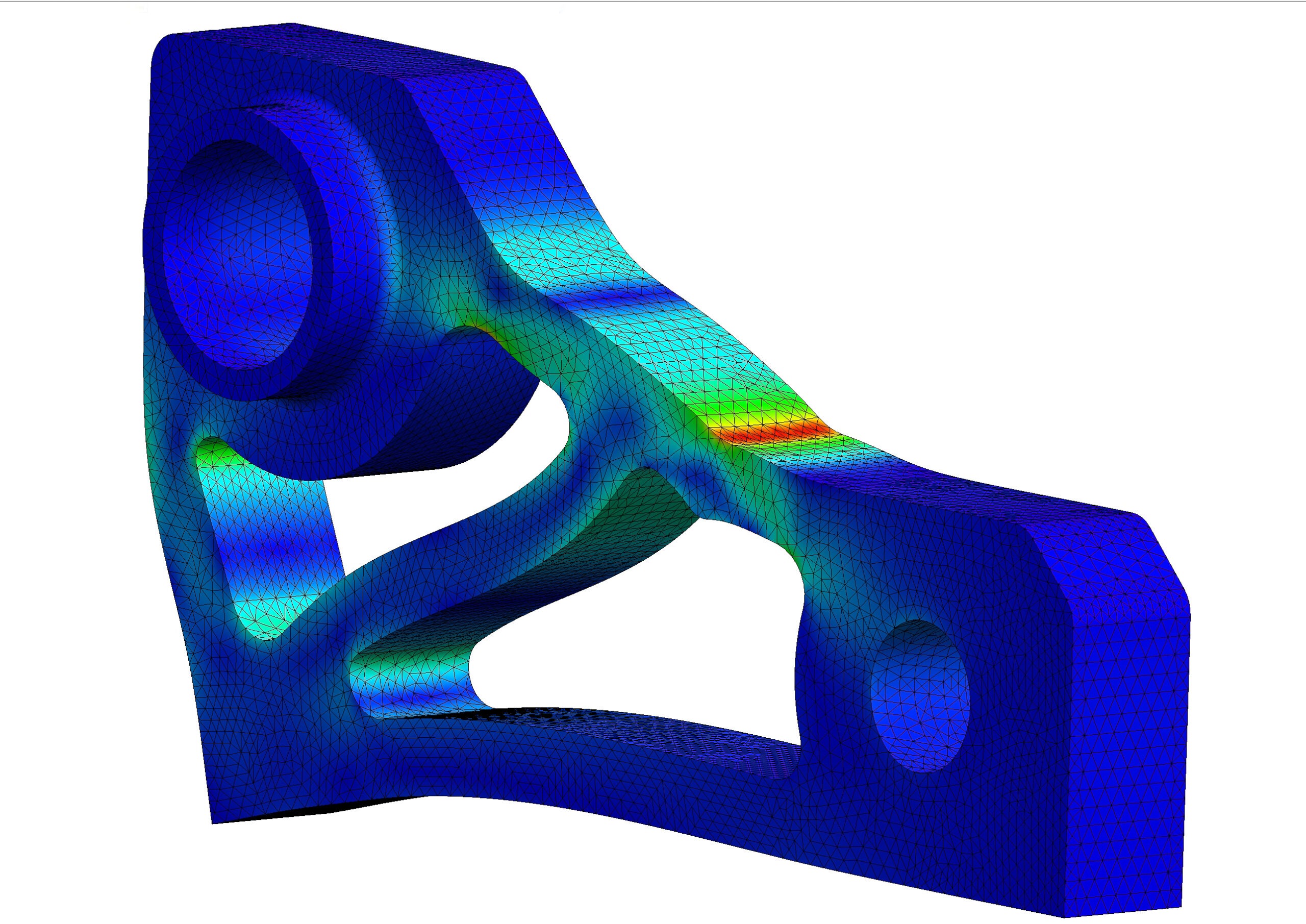

In the realm of engineering, 3D laser scanning plays a pivotal role in creating highly precise models of a project in order to replicate and manufacture.

These detailed 3D models facilitate design planning and quality assurance, ultimately enhancing project efficiency and reducing errors.

Manufacturing:

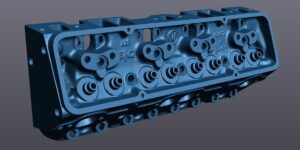

3D laser scanning serves a multitude of purposes in the manufacturing industry.

3D laser scanning serves a multitude of purposes in the manufacturing industry.

It is an indispensable tool for quality control, enabling manufacturers to inspect products with meticulous accuracy.

Moreover, it supports reverse engineering efforts, allowing companies to recreate and enhance existing components or products. Part inspection, essential for maintaining quality standards, is also streamlined through this technology.

Cultural Preservation:

The preservation of our cultural heritage is greatly enhanced by 3D laser scanning. This technology excels in the meticulous documentation of historical artifacts, sculptures, and buildings.

It allows curators, conservators, and historians to create precise 3D records, aiding in the restoration and long-term preservation of these valuable cultural assets.

Forensics:

3D scanning is a crucial tool for crime scene analysis and accident reconstruction. It enables investigators to document and analyze scenes with a high degree of precision.

By capturing three-dimensional data of the scene, it assists in recreating events and understanding critical details, which can be pivotal in legal investigations.

Factors Influencing 3D Laser Scanning Cost

To break down the cost factors associated with 3D laser scanning, the cost of a 3D scanning service can vary widely depending on several key factors.

Understanding the following eight factors will help you estimate the expected 3D laser scanning cost.

-

Project Scope and Size

The size and complexity of your project are primary cost determinants. Larger and more intricate projects typically require more scanning time, data processing, and potentially specialized set up.

Although it may seem that larger projects always take longer, scanning a small object for reverse engineering can take a considerable amount of time because of the tiny intricacies.

-

Scan Resolution and Accuracy

The level of detail you require in your scans directly affects costs. Higher resolution and accuracy demand more time and may necessitate advanced scanning equipment.

Not all 3D scanners are created equal. When working with a service provider, price will be reflective of the caliber of scanner the company has in their lineup.

If precision is crucial for your project, expect to pay more for the increased data collection and processing efforts. You will not get aerospace-quality data from a $5,000 scanner.

-

Equipment and Technology

Different projects may require specific types of 3D laser scanning equipment. The cost of renting or operating this equipment varies. State-of-the-art scanners capable of capturing finer details tend to be more expensive.

-

Scan Environment

The environment in which scanning takes place can influence costs. For example, scanning outdoors might require additional measures to deal with weather conditions or to manage crowd control on a construction site.

-

Travel and Logistics

If the scanning company needs to travel to your project site, travel and logistics expenses will be factored into the overall cost. Proximity to the scanning provider can significantly impact these costs.

However, one beautiful feature of some of the most technologically advanced service providers is their ability to conduct mobile 3D scanning service. Scanners working with these teams fit into a carry-on case and are flown in the main cabin to the scan site.

-

Data Processing and Modeling

Once the scan data is collected, it needs to be processed and converted into 3D models or point clouds.

The complexity of the data and the desired output affect the time and expertise required for data processing, thereby impacting costs.

Project Timeline

Urgency can drive up costs. If you have a tight project timeline, the scanning company may need to allocate additional resources or work extended hours to meet your deadlines, which can result in higher expenses.

-

Additional Services

Some projects may require extra services such as registration (aligning multiple scans into a single model) or CAD modeling. These additional services will incur additional charges.

Typical 3D Laser Scanning Cost Ranges

Given the numerous variables involved, it’s challenging to provide an exact cost without specific project details. However, here’s a general range to give you an idea:

Small-Scale Projects:

Small projects with straightforward requirements, such as scanning a single object, may cost anywhere from $500 to $2,000.

Medium-Scale Projects:

Projects with multiple components or large, remote locations can range from $2,000 to $10,000.

Think of a wind turbine, medical agitators, buses, planes, and more.

Remember, these are just rough estimates, and the actual cost can vary significantly based on your unique project specifications.

Tips for Managing 3D Laser Scanning Costs

While 3D laser scanning can be an investment, there are ways to manage costs effectively:

-

Define Clear Objectives:

Establish precise project goals to avoid unnecessary scanning or data processing.

-

Prioritize Needs:

Focus on the essential aspects of your project to avoid overpaying for excessive detail or services. Do you need an STL only? CAD files?

Review our sample folder to verify the type of file deliverables that match your project goals.

-

Get Multiple Quotes:

Request quotes from several reputable scanning providers to compare pricing and services.

-

Plan Ahead:

Everyone wants their project done, yesterday. Avoid rush fees by planning your project well in advance and allowing for a reasonable timeline.

-

Collaborate with Experts:

Open communication is key! Work closely with the scanning company to optimize project scope and specifications for cost-efficiency.

3D Laser Scanning Cost Conclusion

3D laser scanning is a powerful technology with a wide range of applications across industries. Understanding the factors that influence 3D laser scanning costs is crucial for budgeting and project planning.

By carefully assessing your project’s scope, resolution requirements, equipment needs, and other variables, you can work with a scanning provider to tailor a solution that meets your objectives while managing costs effectively.