Are you looking to incorporate 3D scanning technology services into your business?

In the competitive industries of engineering and manufacturing, precision, speed, and efficiency are no longer optional — they’re essential. Companies that adopt cutting-edge tools early often set the standard in their industries. One of the most impactful of those tools is 3D scanning technology.

Whether you’re designing complex components, reverse engineering legacy equipment, or ensuring quality control at scale, 3D scanning is no longer a niche solution — it’s a core part of how modern businesses innovate, compete, and grow.

What Is 3D Scanning Technology — And Why It Matters

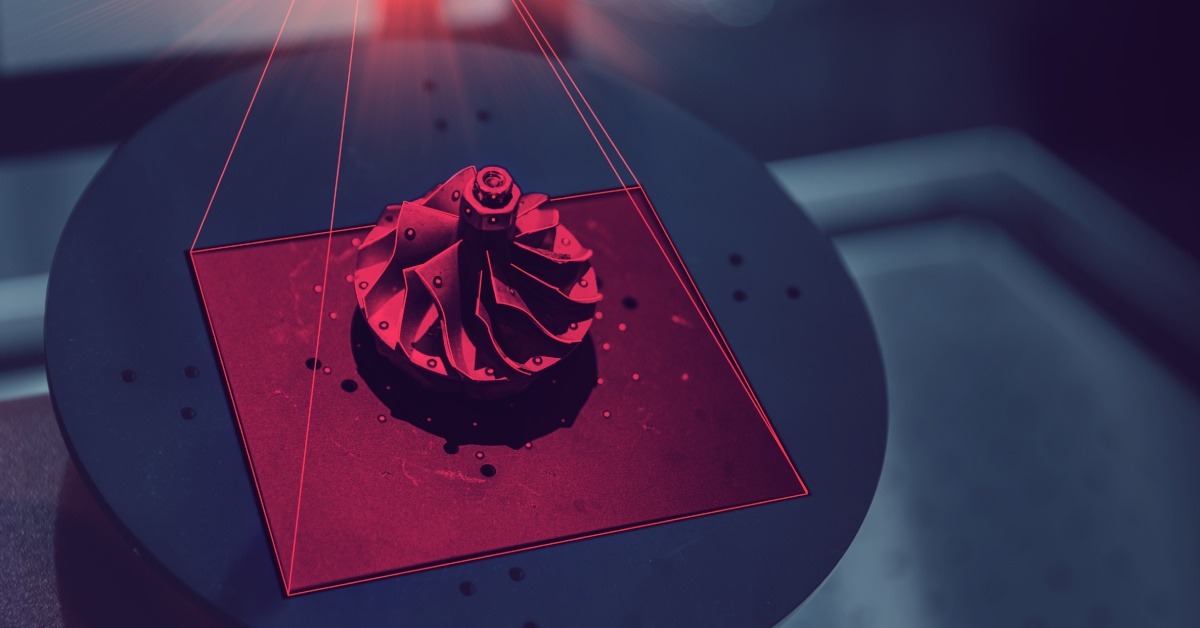

At its core, 3D scanning technology is a non-contact method for capturing the exact shape, size, and geometry of a physical object with micron-level accuracy. Using laser or structured light systems, scanners collect millions of data points in seconds, creating a “point cloud” — a digital 3D map that replicates your part, product, or environment with extraordinary detail.

What makes this technology so transformative for businesses is not just the data itself, but what you can do with it. From that point cloud, engineers generate highly detailed 3D models that integrate directly into CAD environments, enabling faster design iterations, more accurate simulations, and smarter decision-making throughout the product lifecycle.

How Businesses Use 3D Scanning To Their Advantage

The value of 3D scanning goes far beyond data capture. It creates opportunities for companies to solve complex challenges, improve workflows, and unlock new revenue streams. Here’s how different types of businesses are using it today:

Manufacturing & Industrial Companies

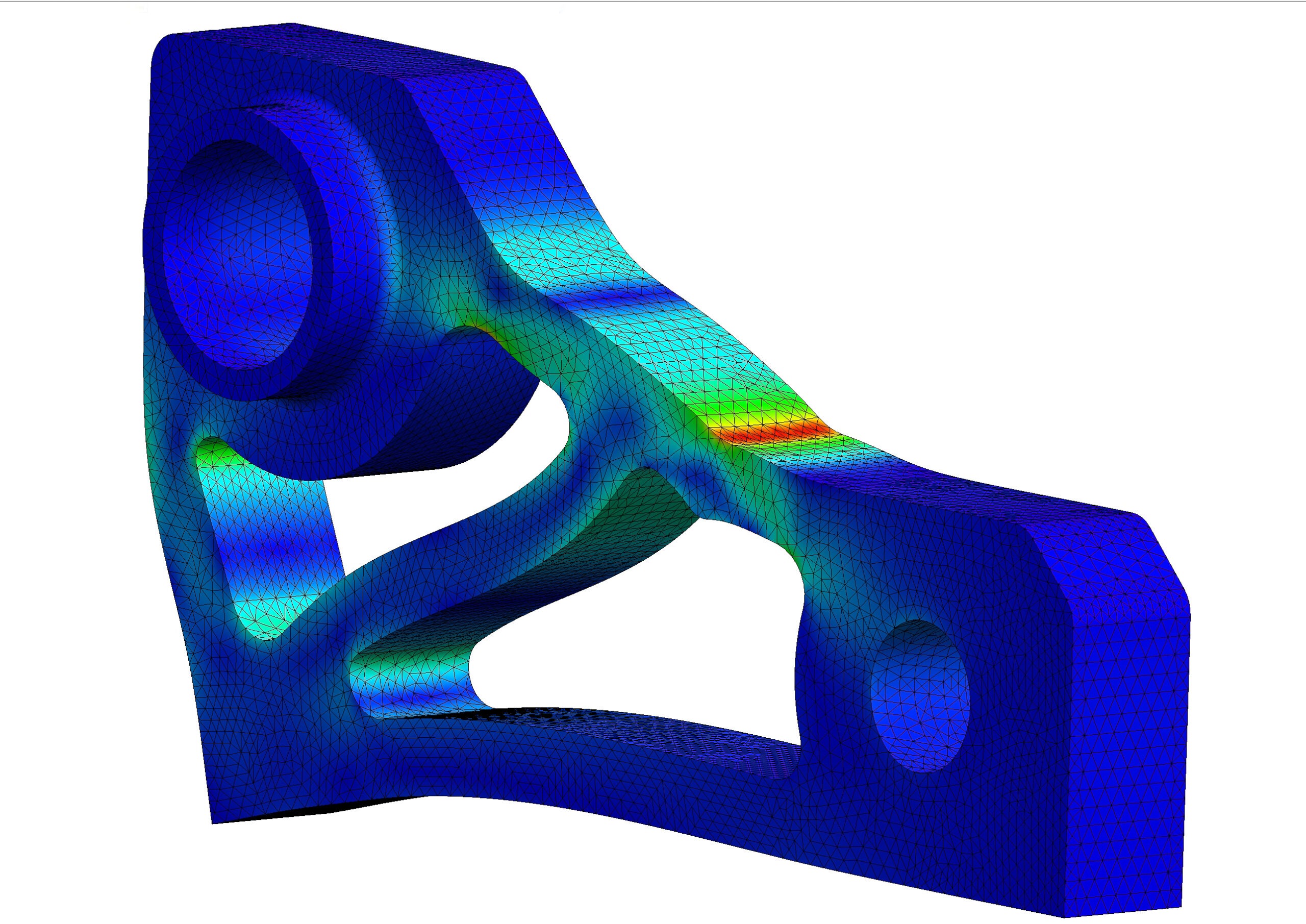

For manufacturers, precision is everything. 3D scanning allows you to digitize existing parts, tooling, or prototypes — dramatically speeding up product development and enabling rapid design improvements. It’s also invaluable for quality control, letting you compare finished parts to original CAD models to verify tolerances and catch deviations early.

Engineering & Product Development Firms

Product design teams use scanning to iterate faster and reduce costly errors. By capturing real-world components and environments, you can simulate how new parts will integrate before they’re ever manufactured. Reverse engineering legacy parts without existing CAD data is another key use case — a game-changer for aerospace, automotive, and heavy industry.

Construction & Architecture Firms

In the construction and architectural sectors, 3D scanning captures highly accurate “as-built” conditions, ensuring that new designs align perfectly with existing structures. This reduces project delays, prevents costly clashes, and supports digital twin initiatives — virtual models of buildings and infrastructure that inform future projects.

Medical, Forensic, And Cultural Organizations

Outside traditional engineering, scanning plays a crucial role in medicine, cultural preservation, and forensic science. From custom prosthetics to artifact digitization, its ability to capture precise, non-contact data opens possibilities that were once impossible with conventional methods.

Business Benefits Of 3D Scanning Technology

Implementing 3D scanning is not just a technical upgrade — it’s a strategic investment that delivers measurable returns across multiple aspects of your business:

Accelerated Development

Reduce design and prototyping cycles by weeks or even months. With 3D models created directly from real-world data, you can validate concepts faster, iterate more effectively, and get products to market sooner.

Reduced Costs & Risk

By catching design flaws early and eliminating manual measurement errors, 3D scanning minimizes rework and costly production delays. Outsourcing scanning also removes the need for expensive equipment investments and staff training.

Improved Product Quality

High-resolution scans allow you to detect even microscopic deviations from design intent, ensuring parts meet strict tolerances. This results in more reliable products, fewer warranty claims, and stronger customer trust.

Future-Proof Capabilities

As industries increasingly move toward automation, digital twins, and smart manufacturing, 3D scanning forms the foundation for those technologies. Businesses that integrate scanning now are better positioned for future innovation.

Why Outsourcing Scanning Often Makes The Most Sense

While some companies choose to invest in in-house scanning systems, many discover that outsourcing is a smarter, more cost-effective choice. Industrial-grade scanners, software licenses, and training require substantial capital — whereas partnering with a professional service provider gives you immediate access to state-of-the-art technology and experienced engineers without the overhead.

This approach allows your team to focus on design, production, and growth — while experts handle the data capture, processing, and CAD deliverables with guaranteed precision.

Final Thoughts: Give Your Business A Competitive Edge

Whether you’re a manufacturer looking to tighten tolerances, a design firm seeking faster iteration, or an engineering company tackling complex reverse engineering projects, 3D scanning technology offers a clear path to higher accuracy, lower costs, and faster innovation.

In an industry where speed, precision, and adaptability define success, adopting 3D scanning isn’t just an upgrade — it’s a competitive advantage. Companies that embrace it today will lead their industries tomorrow.

Ready To Bring 3D Scanning Into Your Business?

In industries where precision, speed, and data-driven decisions define competitive advantage, adopting 3D scanning technology isn’t an option — it’s essential. Whether you’re a manufacturer refining part tolerances, a design firm iterating faster, or a company reverse-engineering legacy components, 3D scanning brings clarity, efficiency, and innovation to your processes.

From individual components to full assemblies and remote scanning, Tangent Solutions provides CAD-ready data you can rely on, on your terms. To see how your business can benefit, explore our 3D scanning services and schedule your free estimate today.

Frequently Asked Questions About 3D Laser Scanning Costs

3D scanning technology helps companies accelerate product development, reduce costly errors, and improve quality control. It captures highly accurate 3D data from physical objects, which can then be used to create CAD models, run simulations, and streamline manufacturing. By adopting this technology, businesses gain a competitive edge — reducing time to market, lowering costs, and improving product reliability.

3D scanning is highly valuable across many industries, but it’s especially impactful for companies in manufacturing, aerospace, automotive, product design, construction, and industrial engineering. It’s also widely used in medical device development, cultural preservation, and forensic analysis. Any business that relies on precise measurement, complex geometry, or rapid prototyping can benefit from implementing 3D scanning into its workflows.

3D scanning drastically reduces development time by allowing teams to capture real-world data and convert it directly into digital 3D models. This eliminates manual measurement errors, speeds up the design iteration process, and makes it easier to integrate existing components into new designs. It’s also a powerful tool for reverse engineering, helping teams recreate parts that lack existing CAD data.

For many businesses, outsourcing is the smarter and more cost-effective choice. High-end scanners, software, and training require significant investment — and using a professional 3D scanning service gives you access to cutting-edge equipment and experienced engineers without the overhead. Outsourcing also ensures accurate, CAD-ready results that integrate seamlessly into your design and production processes.

Yes — quality control is one of the most common and impactful uses of 3D scanning. By comparing a scanned part to its original CAD model, manufacturers can detect even microscopic deviations and confirm that components meet strict tolerances. This ensures higher product reliability, reduces rework, and minimizes the risk of costly production issues.