As companies across aerospace, manufacturing, automotive, and product design adopt more advanced digital tools, 3D scanning services have become an essential part of modern engineering workflows. Whether you’re reverse-engineering a legacy part, inspecting components for quality control, or capturing complex geometry for CAD modeling, professional scanning can save significant time and reduce costly errors.

But how much do 3D scanning services cost — and what should you expect to pay? In this guide, we’ll break down typical pricing, explain the factors that influence cost, and help you estimate your project’s budget with confidence.

Average Cost Of 3D Scanning Services

The price of 3D scanning services depends heavily on project size, complexity, and deliverables. However, most professional scanning projects fall into these ranges:

- Small objects or components: $150 – $500

- Medium-sized parts or assemblies: $500 – $2,000

- Large objects (vehicles, machinery, architectural): $2,000 – $10,000+

For ongoing or multi-part projects, many companies choose day-rate pricing, typically ranging from $1,200 – $3,500/day for metrology-grade scanning and CAD deliverables.

Key Factors That Impact 3D Scanning Cost

1. Size & Complexity Of The Project

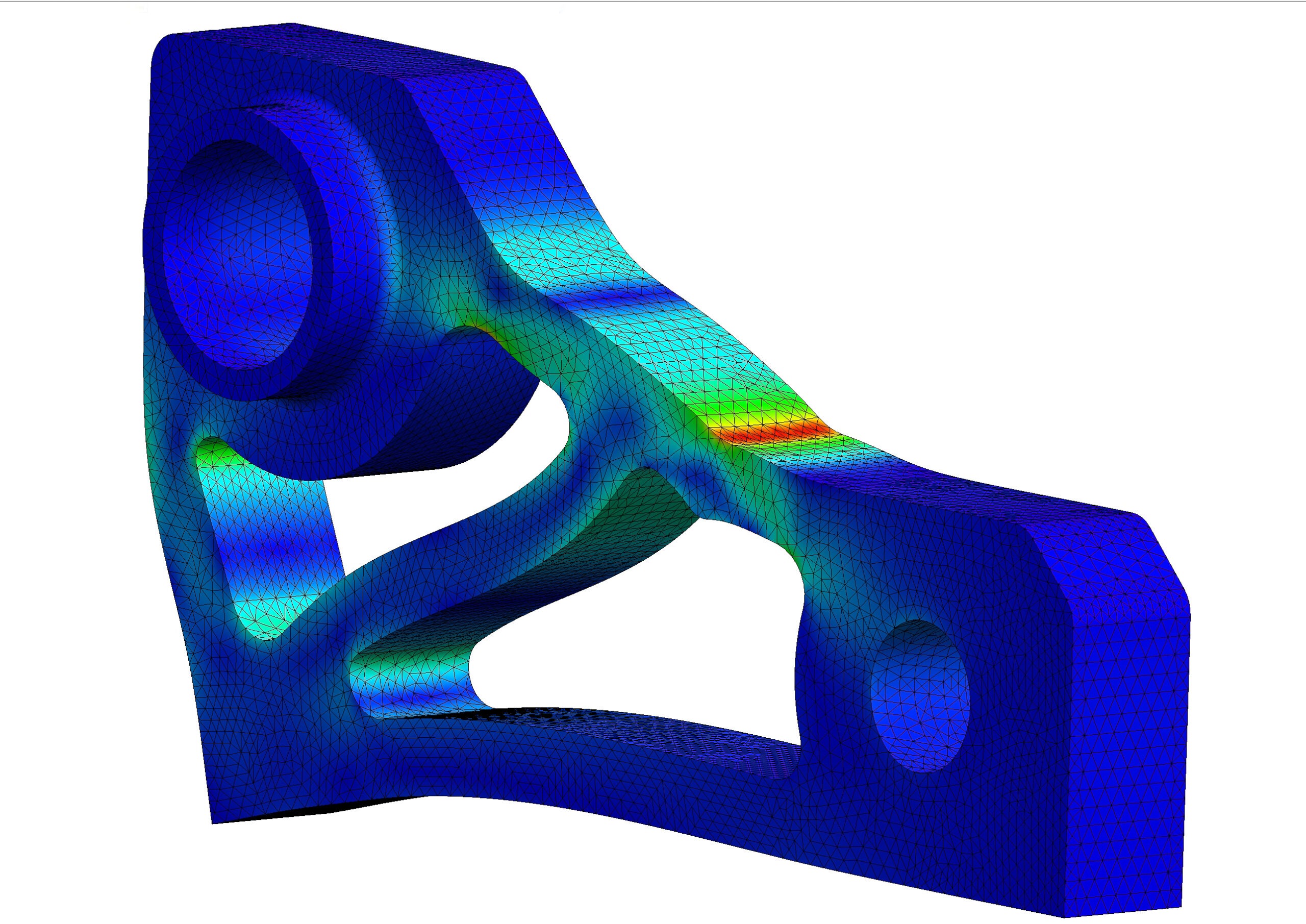

Larger objects or assemblies require more scanning time, more targets, and more complex post-processing. For example, scanning a turbine blade may take hours, while a full aircraft fuselage can require several days.

2. Accuracy & Resolution Requirements

Metrology-grade scanning (±0.020 mm) costs more than standard scanning. Industries like aerospace and medical devices often require higher tolerances, which affect both scan time and file preparation.

3. Deliverable Types (Mesh vs. CAD)

Raw mesh files (STL, OBJ) are less expensive, but most manufacturing workflows require reverse-engineered CAD models (STEP, IGES, XT), which increase cost due to engineering labor.

4. On-Site vs. In-House Scanning

Bringing scanning equipment to your facility adds travel time, setup, and environmental control — but often saves you logistics costs on large or immovable parts.

5. Turnaround Time

Expedited or rush scanning services typically include premium charges due to resource allocation and prioritization.

Real-World Applications (And ROI)

Businesses across multiple industries are investing in 3D scanning because the ROI often outweighs the initial cost:

- Manufacturers reduce rework by catching tolerance errors early.

- Design engineers accelerate development by converting physical parts into editable CAD data.

- Construction and architecture firms scan existing conditions to prevent costly on-site conflicts.

- Aerospace and defense contractors digitize legacy parts with no existing CAD data.

These efficiencies often save weeks of development time and tens of thousands of dollars in downstream production costs.

Why Outsourcing Scanning Is More Cost-Effective Than Buying

While entry-level scanners are available for a few thousand dollars, metrology-grade systems can exceed $100,000 — not including software, calibration, and staff training. Outsourcing to a team like Tangent Solutions lets you access cutting-edge equipment, expert engineers, and precise data without capital expense or risk.

Get A Custom Quote For Your Project

Every project is unique — and so is its pricing. Whether you need a single component digitized or full-scale scanning for an entire production line, our engineering team can deliver CAD-ready data on time and on budget.

Contact us today for a free project estimate or learn more about our 3D scanning services to see how we can support your next engineering challenge.

Frequently Asked Questions About 3D Scanning Costs

The most affordable option is to work with a professional scanning service on a per-part basis rather than purchasing equipment. This eliminates hardware, software, and training costs while ensuring accurate results.

Yes. Many clients only need one or two components scanned, and pricing for single-part projects often starts around $150 – $300 depending on size and detail requirements.

Simple scans can take under an hour, while complex projects may require multiple days, especially when detailed CAD modeling is needed. Turnaround time is typically 3 – 10 business days.

Yes — reputable service providers like Tangent Solutions deliver all scan data and CAD files, and you retain full ownership for future use.