In modern engineering, 3D CAD modeling services are a critical part of turning ideas into functional, manufacturable solutions. Whether you’re developing new products, reverse-engineering legacy components, or preparing parts for production, 3D CAD models provide the foundation for precision, iteration, and innovation.

For companies without in-house CAD specialists, outsourcing this work is often the most efficient and cost-effective solution. By partnering with a dedicated engineering team, you gain access to specialized tools, industry expertise, and scalable resources — without the overhead of building and training an internal department.

What Is 3D CAD Modeling?

CAD, Computer-Aided Design, is the process of creating, modifying, analyzing, and optimizing product designs using advanced software. 3D CAD modeling extends beyond basic drafting, enabling engineers to build highly detailed, fully parametric digital representations of components, assemblies, and systems.

These digital models form the backbone of modern manufacturing workflows. They allow teams to:

- Virtually prototype and test designs before physical production

- Perform interference and tolerance checks during the design phase

- Optimize part geometry for strength, weight, or manufacturability

- Export models directly to CAM, additive manufacturing, or inspection tools

At Tangent Solutions, our engineering team leverages industry-standard platforms such as SOLIDWORKS to deliver precise, production-ready models tailored to your exact specifications.

Why Companies Outsource 3D CAD Modeling

Building a CAD department internally is time- and resource-intensive. It requires expensive software licenses, specialized hardware, and highly trained engineers. Outsourcing removes those barriers while giving you direct access to a team that works with CAD data daily across multiple industries.

Some of the most common reasons companies choose to outsource include:

1. Increased Accuracy and Design Confidence

3D CAD modeling minimizes human error by automating calculations, dimensioning, and interference detection. Parametric modeling allows you to visualize assemblies in detail and make rapid adjustments before committing to manufacturing.

2. Greater Design Efficiency

Digital workflows significantly shorten design cycles. Engineers can easily modify existing models, explore alternative design paths, and generate new iterations without starting from scratch — increasing productivity while accelerating time-to-market.

3. Cost Optimization

Outsourcing CAD work reduces overhead by eliminating the need for full-time staff, training, and expensive software infrastructure. It also reduces the number of physical prototypes needed, saving both time and material costs.

4. Access to Specialized Expertise

Our team has extensive experience across industries including aerospace, automotive, marine, industrial equipment, and consumer products. That depth of knowledge ensures that your designs are optimized for real-world performance and manufacturability.

Applications of 3D CAD Modeling Services

The versatility of 3D CAD makes it a powerful tool throughout the product lifecycle. Here are some of the most impactful use cases:

Product Development

Our engineers create fully parametric 3D models to support early-stage concept design and product visualization. Complex geometries, assemblies, and mechanical systems can be tested digitally before physical prototypes are produced.

Rapid Prototyping

3D CAD models serve as the digital blueprint for rapid prototyping — whether you’re 3D printing components for functional testing or preparing parts for short-run production. Advanced modeling techniques such as hollow structures or lattice infills can further reduce material usage and production time.

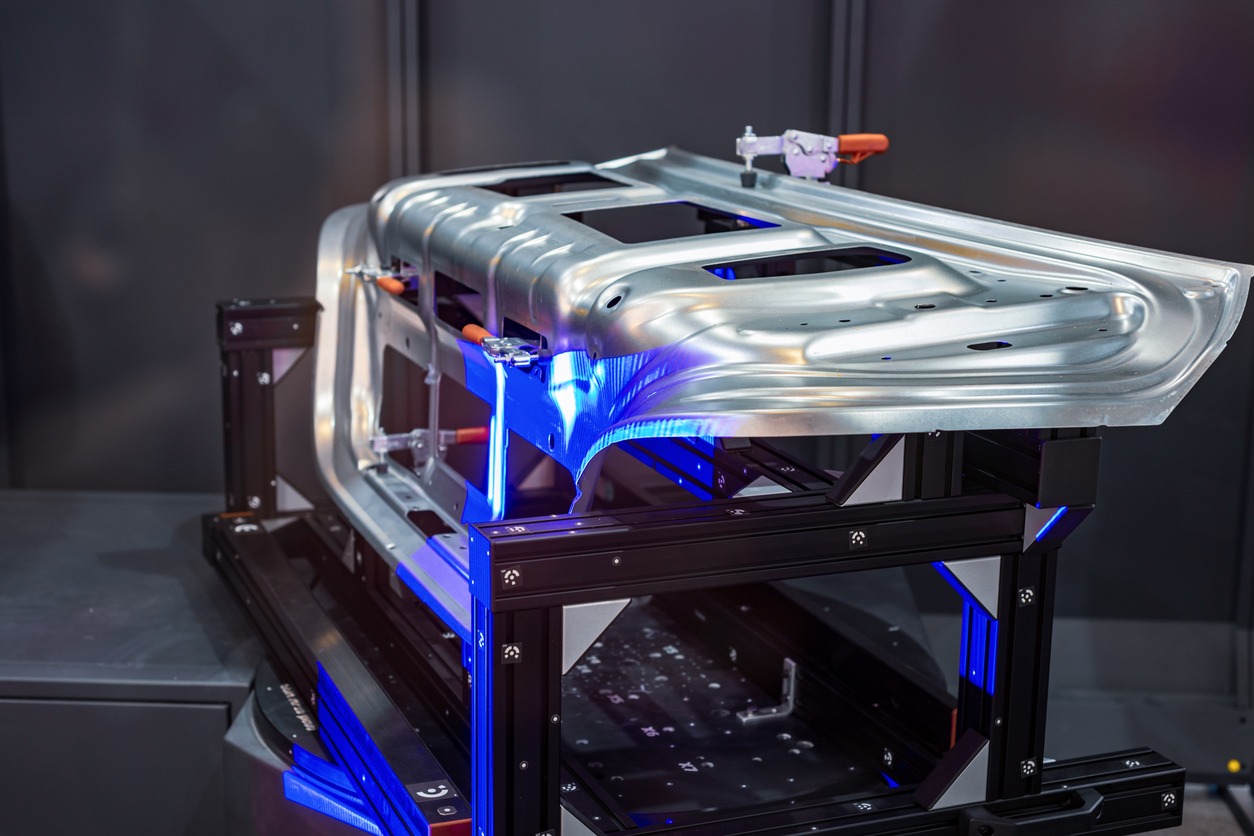

Reverse Engineering

When physical parts exist without CAD data, we combine high-accuracy 3D scanning with advanced modeling to recreate fully functional digital twins. These models can be modified, optimized, or integrated into new designs with ease.

Manufacturing Documentation

From 3D assemblies to 2D fabrication drawings, CAD models form the basis of accurate documentation for machining, laser cutting, mold making, or additive manufacturing. Parametric associations ensure that any change to a model automatically updates the associated drawings.

Types of 3D CAD Models

Different projects require different modeling approaches. Our team is proficient in all major types:

- Wireframe Models – A skeletal representation useful in conceptual stages.

- Solid Models – Fully defined 3D volumes suitable for manufacturing workflows.

- Parametric Models – Feature-driven models that enable global design changes, ideal for complex assemblies and iterative development.

Partner With a Trusted CAD Engineering Team

Working with an experienced engineering partner ensures that every 3D model is accurate, manufacturable, and tailored to your project’s objectives. At Tangent Solutions, we act as an extension of your team — providing the precision, scalability, and expertise required to meet demanding engineering standards.

Explore our 3D CAD design services to learn how we support product development, reverse engineering, and manufacturing across multiple industries.

Ready to discuss your project? Call us at 949-345-0611 or schedule a free estimate to speak directly with one of our engineers.