Converting a 3D CAD drawing to 2D format is a valuable skill for engineers and designers. This process allows you to extract the essential information from a 3D model and represent it in a 2D format, often in the form of technical drawings.

In this guide, we’ll explore the steps and techniques involved in this transformation, enabling you to create clear and precise 2D drawings that accurately convey your design’s critical details.

Whether you’re working on mechanical parts, architectural plans, or any other project, this skill can streamline communication and enhance the documentation of your designs.

From Conceptual 3D CAD Drawings to 2D Format

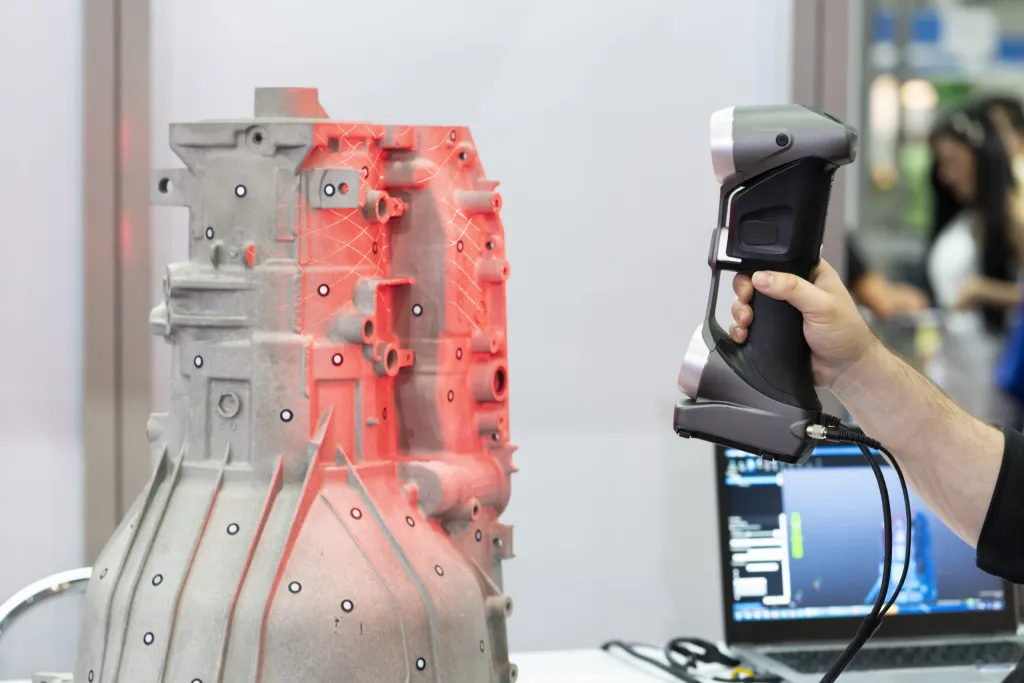

Computer-Aided Design files, CAD, are created using specialized software that allow designers to create detailed digital representations of objects, products, or systems. Services that include CAD design or reverse engineering, will result in universal CAD files.

This software allows the export of the 3D file in common, universal formats like STEP, IGES, and XT.

With this universality, CAD files can be shared from company to consumer, engineers, or manufacturers.

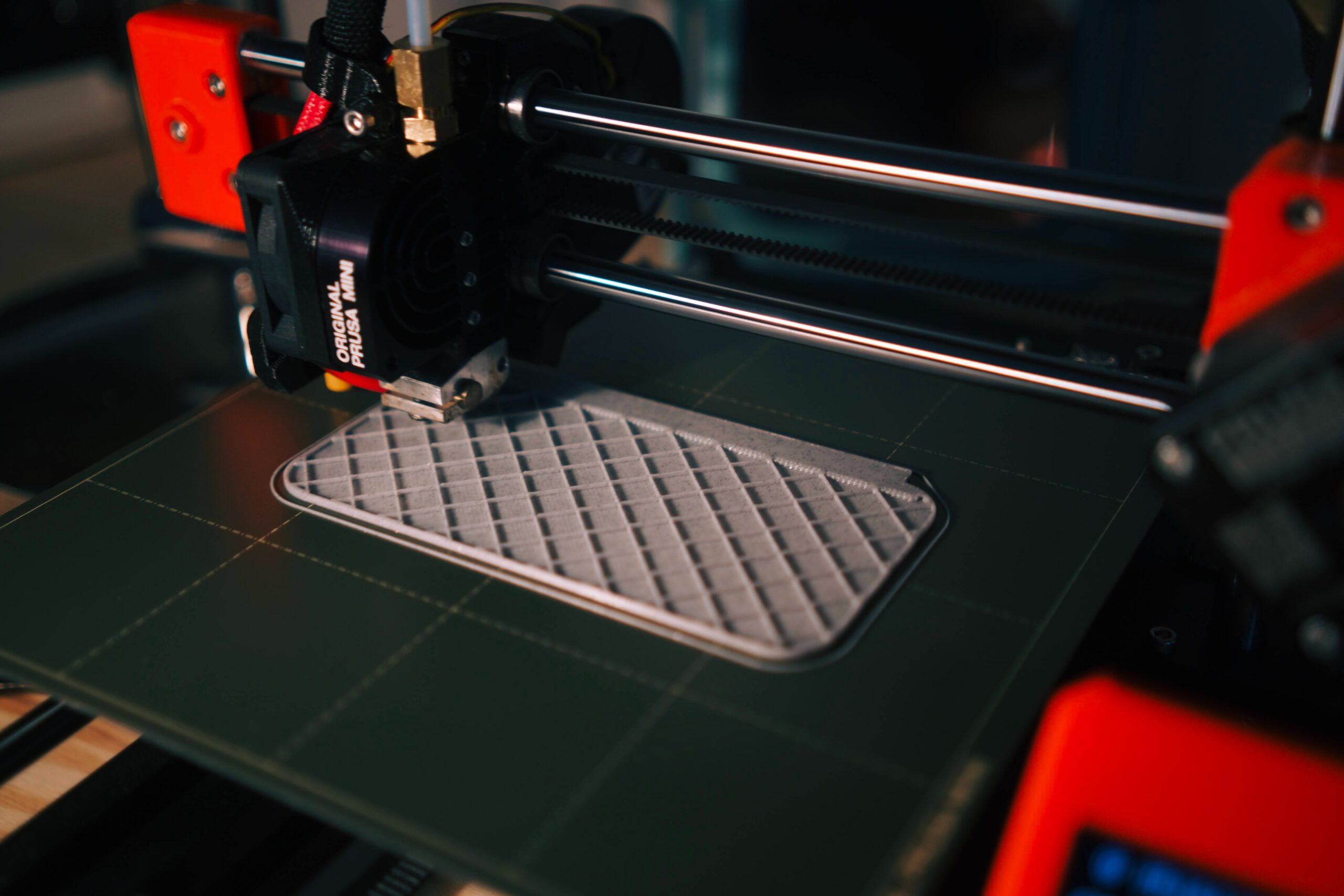

The manufacturing industry, for example, imports CAD files into Computer-Aided Manufacturing, CAM, software to create toolpaths and guide the specific manufacturing process.

Why Are 2D Prints Important?

2D drawings maintain their significance alongside CAD files for several key reasons.

Firstly, they offer clarity and simplicity, providing an easily understandable representation of designs for diverse audiences, including non-technical stakeholders.

Additionally, 2D drawings adhere to industry standards, ensuring consistency and effective communication among professionals.

They also fulfill legal and contractual requirements in various fields and serve as crucial records for documentation and record-keeping.

2D drawings facilitate communication, collaboration, annotation, and markups, making them accessible and cost-effective, even in less technologically advanced environments.

Their role in problem-solving and visualization remains vital, helping in the analysis of complex geometries and spatial relationships.

While CAD provides powerful tools for design, 2D drawings are indispensable due to their compatibility with standards, accessibility, and role in legal compliance and record-keeping.

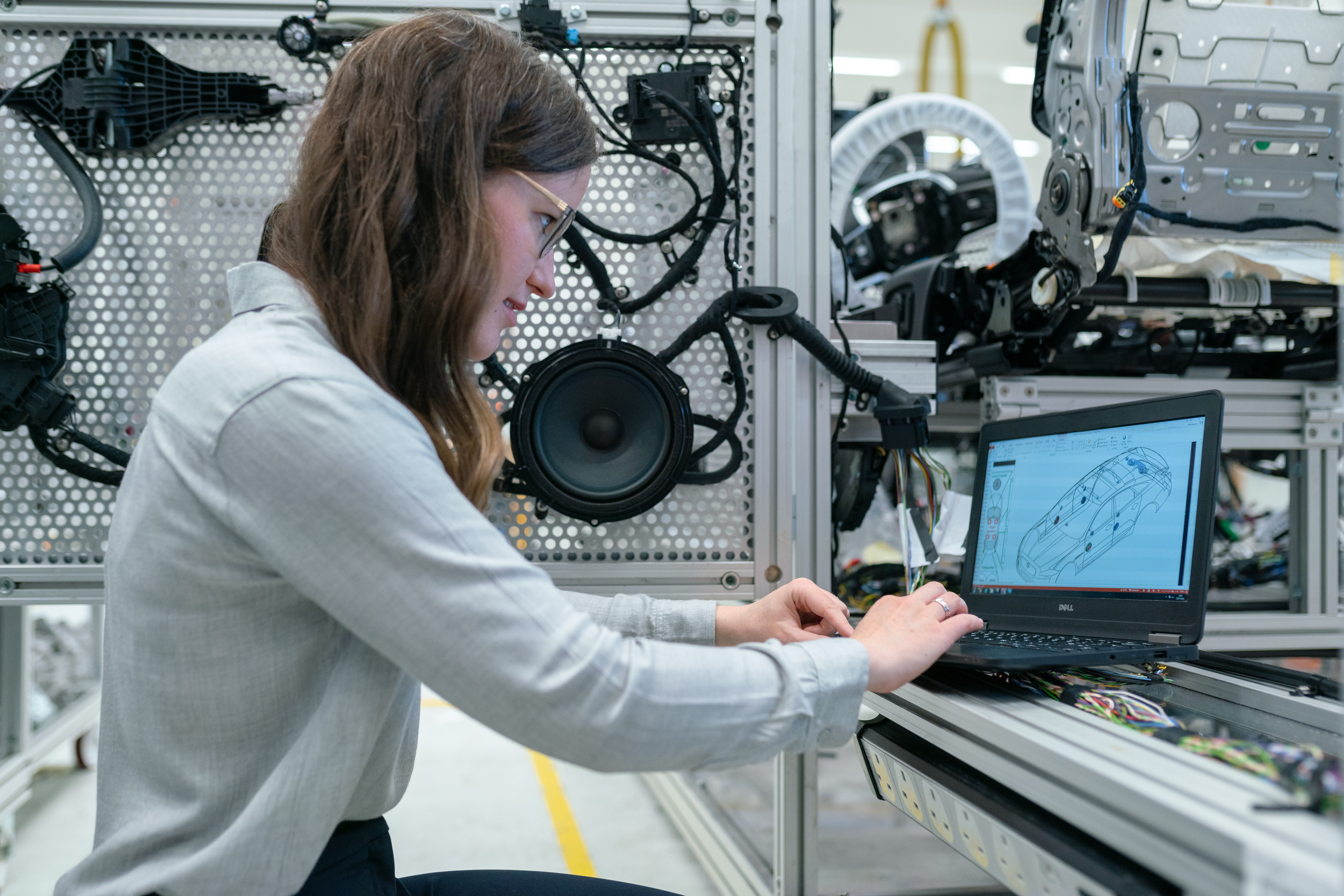

Professionals often use a combination of 2D and 3D representations to harness the strengths of each approach, ensuring effective communication and design development in projects of varying complexities.

Why Create A CAD Drawing to 2D?

Converting 3D CAD drawings to 2D technical drawings provides a supplementary references to a 3D CAD model. As mentioned beforehand, they provide a clear, simplified representation of an object or design, making them easier to understand for a broad audience.

This simplicity is important to clients, contractors, or regulatory bodies, who may not be familiar with CAD software or cannot open the formats.

2D drawings are the industry standard for many industries. Government agencies, manufacturing, and project management will not proceed with a goal without having copies.

These drawings also provide a quick reference of dimensions, views, revisions, and scale without having to open the software.

How to Create 2D Technical Prints

The creation of CAD drawing to 2D technical drawings is of paramount importance in the manufacturing realm. Uncertainty in drawings can result in costly errors, rework, and project delays.

As mentioned before, some machine shops even decline projects with inadequate drawings, marked by missing dimensions, unclear design elements, or subpar detailing.

To minimize the chances of having drawings returned for revisions, designers should focus on producing clear and professional manufacturing drawings from the outset. Here’s a comprehensive guide on best practices:

1. Establish a Comprehensive Template

Select a drawing template that matches your project’s requirements. Templates often include title blocks with fields for information like the project name, company name, and sheet number.

Choose a template that complies with industry standards or your organization’s preferences.

Title blocks should feature essential information such as company details, address, responsible personnel (designer, checker, approver), drawing title, revision references, sheet size, view alignment convention, tolerances, and primary scale.

2. Set Drawing Scale and Tolerance:

Establish the scale for your 2D prints. The scale determines the relationship between the dimensions in the 2D drawing and the real-world measurements.

Common scales include 1:1 (full scale), 1:2, 1:10, and so on. The appropriate scale depends on the size of your model and the size of the paper you’ll print on.

Tolerances should also be noted. Choose reasonable tolerances suitable for the manufacturing process of your choosing.

Most modern CNC machines, usually around ±0.005″ for distance dimensions. You can customize tolerances based on the specific part and produc

tion method, but sticking to general tolerances can help manage design expectations and control costs.

3. Arrange and Annotate Views:

Arrange the views on the drawing sheet, ensuring they are clear and organized. Use dimensioning and annotation tools to add labels, dimensions, notes, and symbols to convey important information about the model.

4. Add Section Views (if necessary):

If your model is complex and requires detailed internal views, you can create section views to reveal the interior components. Specify the cutting plane and direction to create these views.

5. Specify Material and Surface Finish

Provide comprehensive material specifications, surpassing a mere listing of the material type.

Additionally, clarify any special instructions related to surface finishing, including edge breaks and deburring, in the notes section of the drawing.

6. Generate a Bill of Materials – BOM

If you’re working with an assembly, you can create a BOM that lists all the components and their quantities. This is crucial for manufacturing and assembly instructions.

7. Check for Accuracy:

Carefully review the 2D drawing for accuracy and consistency. Ensure that dimensions are correctly applied, annotations are clear, and that the drawing complies with any relevant standards.

Conclusion

Creating 2D prints from CAD files requires attention to detail and a good understanding of the specific CAD software you’re using.

It’s crucial to follow industry standards and best practices to ensure that the 2D drawings accurately convey the design information needed for manufacturing, construction, or other purposes.