3D laser scanning is one of the most accurate and efficient ways to gather ultra-precise data for engineering, product development, and manufacturing projects. But one of the most common questions companies ask before starting is: how much does a 3D scan cost?

If you’re considering integrating 3D scanning services into your workflow, understanding the cost structure — and what factors influence pricing — is key to planning your project effectively.

This guide breaks down everything you need to know, from project size and detail requirements to deliverables, turnaround time, and provider expertise.

What Is 3D Laser Scanning?

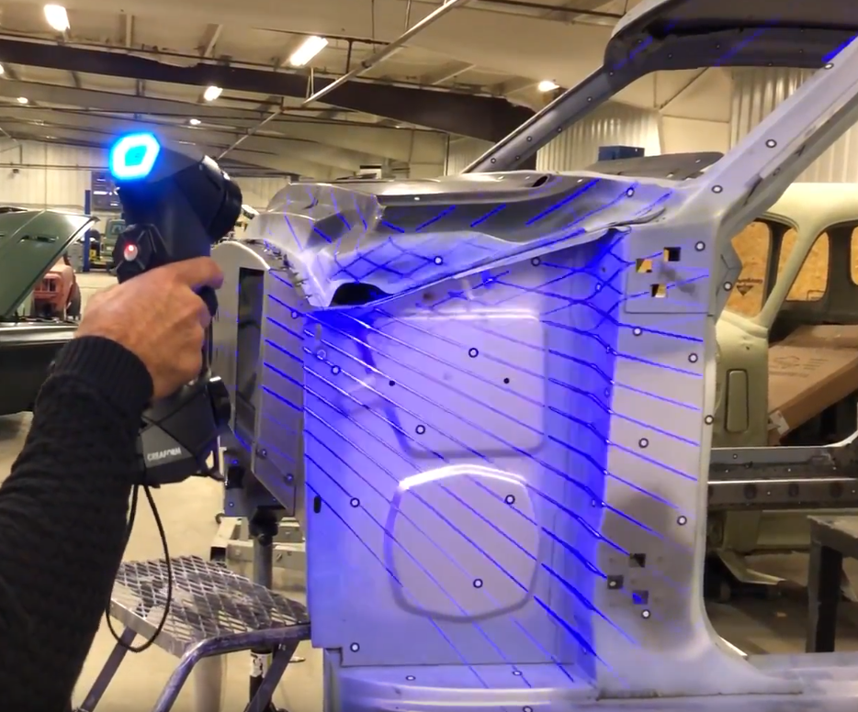

3D laser scanning is the process of capturing the shape, size, and geometry of real-world objects with high precision to create a digital 3D representation. Using laser beams to collect millions of data points, the scanner records a detailed “point cloud” that defines the object’s surfaces and features with remarkable accuracy — often down to 0.020 mm.

Once captured, this data can be processed into CAD models through mesh-to-CAD conversion — a critical step for downstream applications such as design, manufacturing, inspection, and quality control.

Industries That Rely on 3D Laser Scanning

3D scanning has transformed workflows across multiple sectors:

-

Manufacturing: Digitizing components for tooling, mold creation, and rapid prototyping.

-

Quality Control: Comparing production parts to original CAD models to identify dimensional deviations.

-

Reverse Engineering: Reconstructing legacy parts, replacing obsolete components, and modifying existing designs.

-

Architecture & Construction: Capturing as-built conditions, performing clash detection, and planning renovations.

Factors That Influence 3D Scanning Costs

Since every project is unique, 3D scanning pricing can vary widely. The most common cost drivers include:

1. Size and Complexity of the Project

Larger objects require more scanning time, data processing, and equipment. Complex geometries may involve multiple scanning angles, specialized setups, and additional labor.

2. Level of Detail Required

High-resolution scans with tight tolerances (e.g., aerospace components) require more scanning passes and processing, increasing cost. Simpler scans with larger margin-of-error tolerances are faster and less expensive.

3. Deliverables and File Types

Basic mesh files (e.g., STL, OBJ) are generally less expensive than fully parametric CAD deliverables (e.g., STEP, IGES, XT). Reverse engineering and advanced post-processing also add to project cost.

4. Quantity of Objects

Scanning multiple parts can reduce the cost per item but increases total project time. Disassembly requirements and part handling logistics can also affect pricing.

5. Additional Services

Mesh cleanup, alignment, CAD conversion, quality inspection, and reporting are often priced separately. These value-added services are essential for most engineering workflows but will affect the final quote.

6. Geographic Location and Logistics

On-site scanning often incurs additional costs for travel, setup, and equipment transport. However, it’s often more efficient for large or immovable objects such as vehicles, structures, or machinery.

7. Turnaround Time

Rush projects requiring expedited data capture and processing are typically billed at a premium due to scheduling and resource allocation.

8. Provider Expertise and Reputation

Reputable engineering service providers with metrology-grade equipment and experienced technicians may charge more — but often deliver higher accuracy, cleaner data, and fewer downstream issues.

Why Choose a Professional Partner

Working with a professional 3D scanning provider ensures more than just accurate data. You also gain access to advanced workflows, engineering expertise, and reliable deliverables that integrate seamlessly into CAD, inspection, and manufacturing processes.

Partnering with a trusted team from the beginning helps you avoid costly design errors, reduce development time, and accelerate time-to-market.

Work With Tangent Solutions

At Tangent Solutions, we specialize in metrology-grade 3D scanning for complex engineering, manufacturing, and product development projects. Our team delivers precise, CAD-ready data on your timeline — whether you need in-house scanning or rapid deployment on-site anywhere in the U.S.

Explore our 3D scanning services to learn more about capabilities, deliverables, and project workflows.

Frequently Asked Questions About 3D Scanning Costs

Costs vary significantly based on project scope, but most professional 3D scanning projects are priced by time or complexity — often using half-day or full-day service rates. Additional factors like resolution requirements, deliverables, and logistics also affect pricing.

Yes. While upfront costs vary, 3D scanning frequently reduces total project costs by minimizing design iterations, speeding up product development, and improving downstream manufacturing accuracy.

Yes — if you need fully parametric CAD models, reverse engineering is required to convert raw scan data into CAD. This adds engineering time but is often necessary for manufacturing, design modification, or simulation.

Absolutely. Tangent Solutions provides mobile scanning services for large, immovable, or field-based projects. Our technicians bring metrology-grade equipment to your location — requiring only access to power — and can scan anything from industrial equipment to vehicles and marine vessels.

The most accurate way is to discuss your project goals, accuracy requirements, and deliverable needs with a provider. Supplying reference drawings, CAD files, or part details helps us generate a precise estimate.