Modern product development moves fast — and companies that can rapidly capture, convert, and deploy 3D data gain a major advantage. But building and maintaining an in-house scanning operation isn’t always practical. Between costly equipment, operator training, calibration, and software, the overhead often outweighs the benefits.

That’s why many engineering and manufacturing teams now choose to outsource 3D scanning to specialized partners. By doing so, they gain instant access to metrology-grade hardware, expert technicians, and CAD-ready deliverables — all without the expense or delay of managing the process internally.

At Tangent Solutions, we help product teams, manufacturers, and R&D groups get the scan data they need to move forward — faster, more accurately, and with less overhead.

Why It Makes Sense to Outsource 3D Scanning

3D scanning is one of the most valuable tools in modern product development. It enables precise digitization of physical components, speeds up reverse engineering, and streamlines inspection workflows. However, owning the technology in-house is often expensive and inefficient — especially for teams that don’t scan every day.

When you outsource 3D scanning, you:

- Eliminate equipment and training costs – No capital investment or specialized staffing required.

- Accelerate turnaround times – Get scan data and CAD models in days, not weeks.

- Access advanced technology – Use high-precision, metrology-grade scanners without owning them.

- Scale on demand – Easily adjust capacity for project spikes or one-off jobs.

- Focus internal resources – Let your engineering team stay focused on design, validation, and production.

Outsourcing isn’t just a cost-saving move — it’s a way to improve data quality, shorten development cycles, and deliver better results to your customers.

What to Look for in a 3D Scanning Partner

Selecting the right service provider is critical to ensuring the quality, usability, and security of your scan data. Here are the five most important factors to evaluate before you outsource 3D scanning:

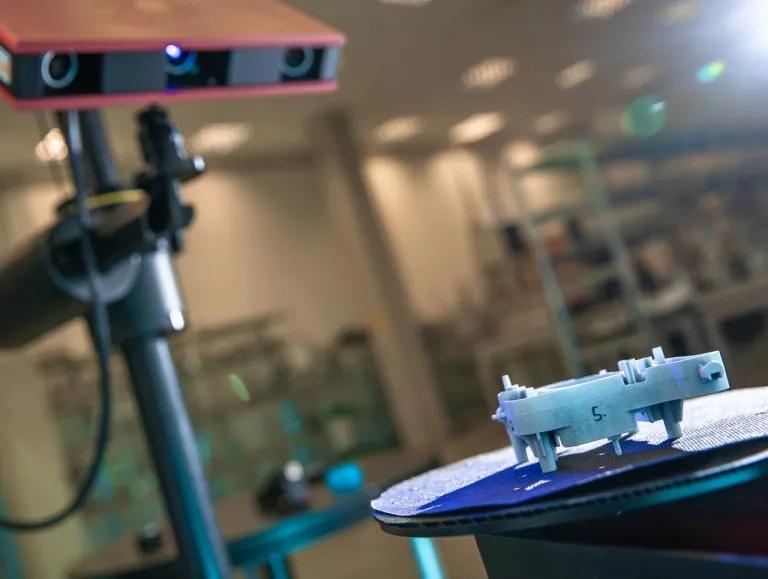

1. Metrology-Grade Equipment

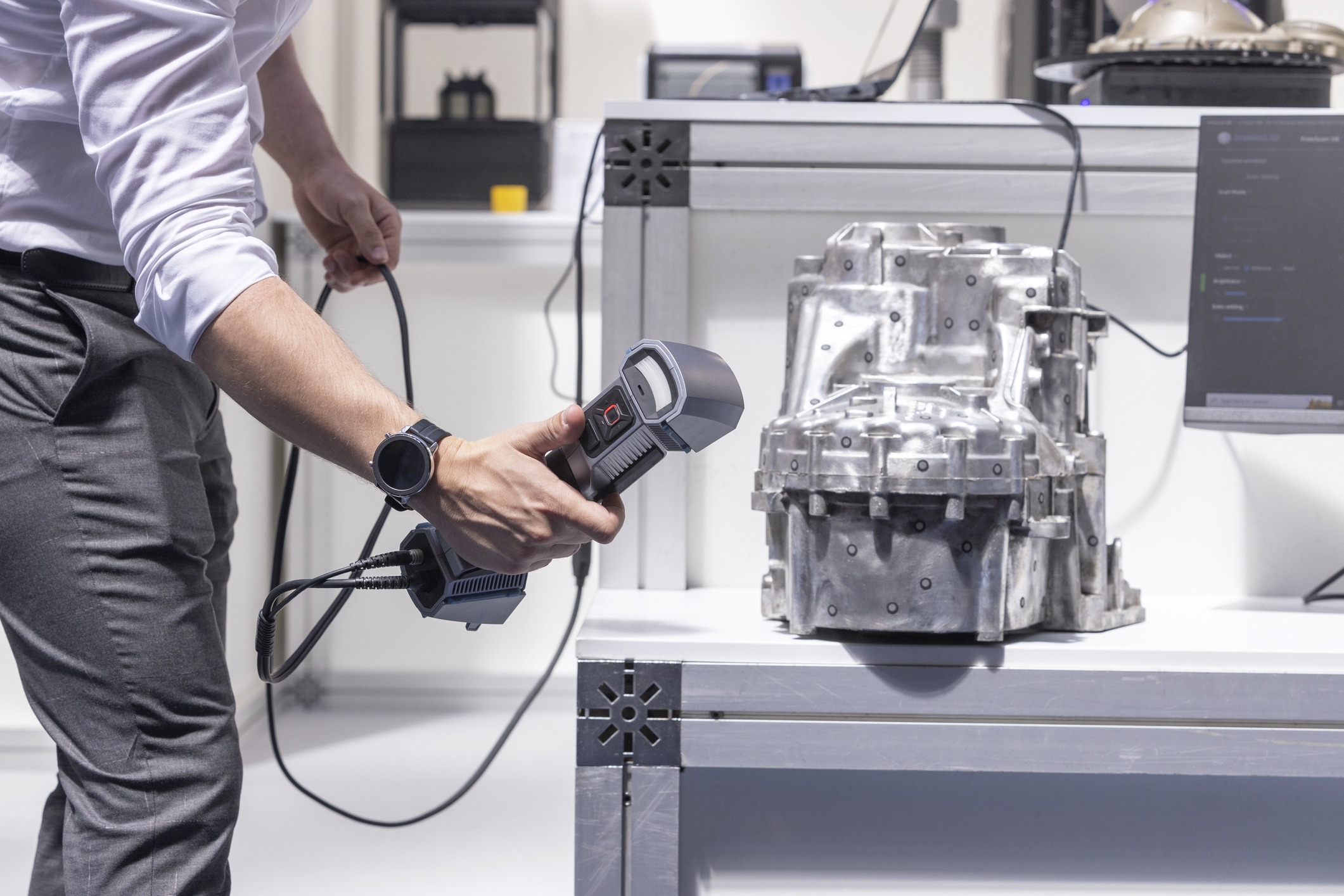

Precision starts with the right hardware. Look for a partner using professional-grade laser or structured-light scanners with tolerances in the ±0.02 mm range — essential for manufacturing, aerospace, and high-tolerance applications.

2. Relevant Industry Experience

Each part type — from castings and injection molds to turbine blades and stamped sheet metal — comes with unique scanning challenges. Choose a provider that has experience with parts similar to yours and understands downstream requirements like CNC machining or quality inspection.

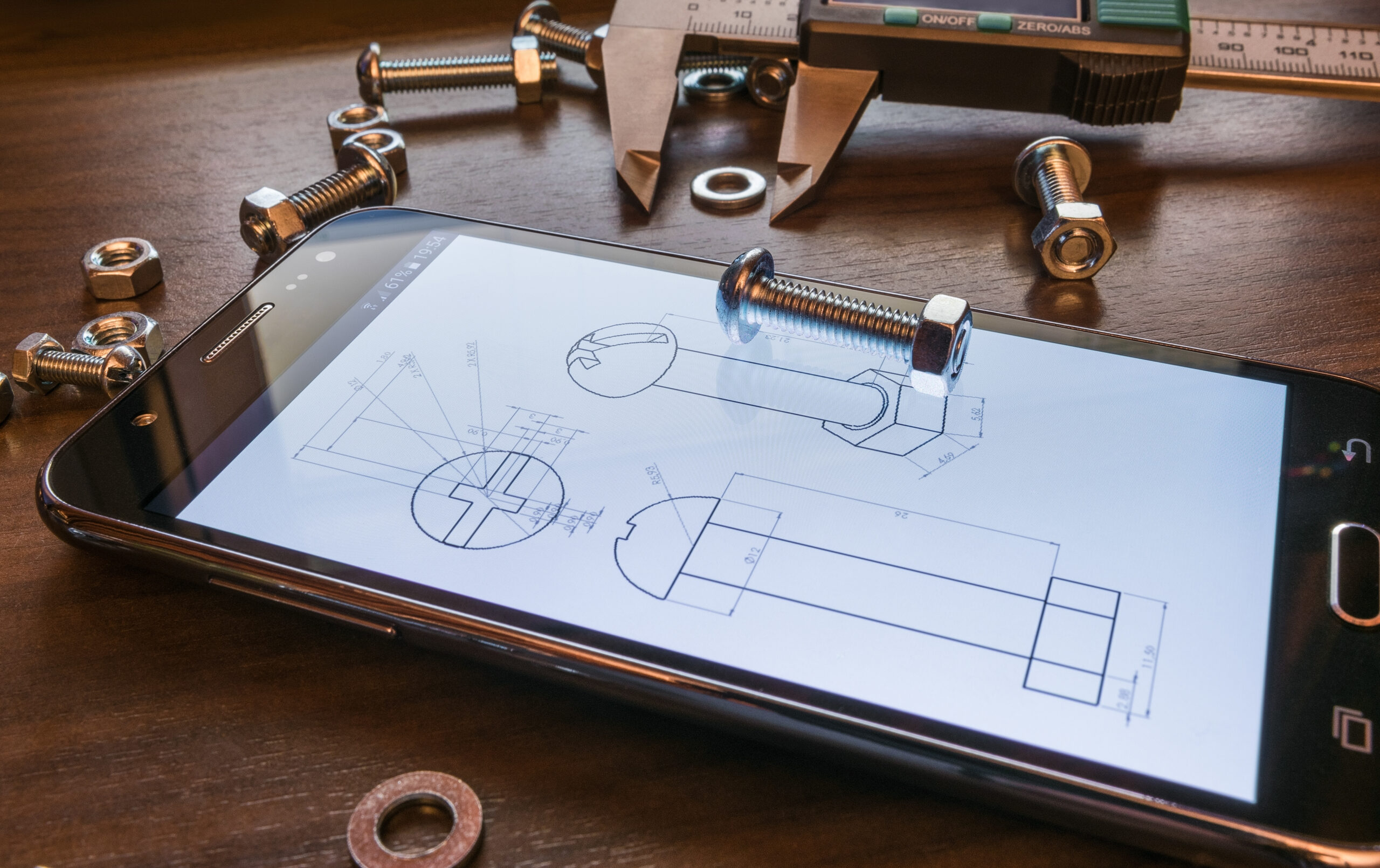

3. Complete Data Workflow

Scanning is only one piece of the puzzle. Ensure your provider can deliver clean, optimized meshes, and if required, fully parametric CAD models compatible with your preferred software environment.

Learn more about our 3D scanning services and deliverable options.

4. Turnaround Time and Scalability

Ask about standard lead times, rush capabilities, and project volume capacity. A good partner can scale quickly without sacrificing quality — ideal for urgent R&D projects or production timelines.

5. Security and Confidentiality

Your designs are valuable. Verify that your provider has clear IP protection policies and secure data handling protocols in place.

Why Engineering Teams Choose Tangent Solutions

Tangent Solutions is a trusted partner to manufacturers, OEMs, and product design teams across North America. We specialize in high-accuracy 3D scanning services for reverse engineering, inspection, and product development — delivering CAD-ready data that integrates seamlessly with your engineering workflows.

Our capabilities include:

- Metrology-grade scanning with ±0.02 mm accuracy using Creaform HandySCAN BLACK Elite.

- Post-processing & mesh optimization for downstream CAD and manufacturing use.

- Reverse engineering and 2D/3D deliverables (STEP, IGES, STL, OBJ, and more).

- Rapid project turnaround with flexible scaling for one-off or ongoing projects.

- Confidentiality protocols to protect your proprietary data. We do not sell or share files.

We act as an extension of your engineering team — delivering reliable, production-ready data without the internal burden.

Our Streamlined Process: From Scan to CAD-Ready Model

When you outsource 3D scanning to Tangent Solutions, the process is straightforward and predictable:

- Submit your part or request a quote – Provide basic part details, tolerances, and intended use.

- Precision scanning – We capture your part using high-resolution laser technology.

- Data processing – Scan data is aligned, cleaned, and optimized.

- CAD modeling / reverse engineering – If required, we deliver fully parametric models.

- Review & delivery – Final files are sent in your preferred format, ready for manufacturing or design.

Here is a sample folder of our most common file deliverables.

This streamlined approach minimizes downtime, ensures accuracy, and keeps your projects moving forward.

Ready to Outsource 3D Scanning? Let’s Talk.

Whether you’re digitizing legacy parts, reverse-engineering tooling, or preparing for production, outsourcing your 3D scanning is one of the fastest and most cost-effective ways to strengthen your product development pipeline.

Call Tangent Solutions today at 949-345-0611 or schedule a free estimate to speak with an engineer about your project.