The utilization of 3D laser scanning extends beyond product design, playing a pivotal role in several applications. One of the largest 3D scanning applications is for engineering purposes.

In engineering, 3D scanning serves as a transformative tool for capturing precise and detailed geometric data of physical objects.

This technology facilitates the digitization of real-world structures, components, or prototypes, allowing engineers to create accurate three-dimensional models.

Engineers leverage 3D scanning applications for various purposes, such as reverse engineering existing components for design improvements, quality control to ensure manufacturing precision, and prototyping to accelerate product development cycles.

The ability to rapidly and accurately capture the intricate details of complex geometries empowers engineers to streamline design processes, troubleshoot issues, and enhance overall efficiency in a wide range of engineering 3D scanning applications, spanning from aerospace and automotive to civil and mechanical engineering.

3D Scanning Applications in Engineering

As we explore many of the 3D scanning applications, engineering specifically has a unique demand for this technology.

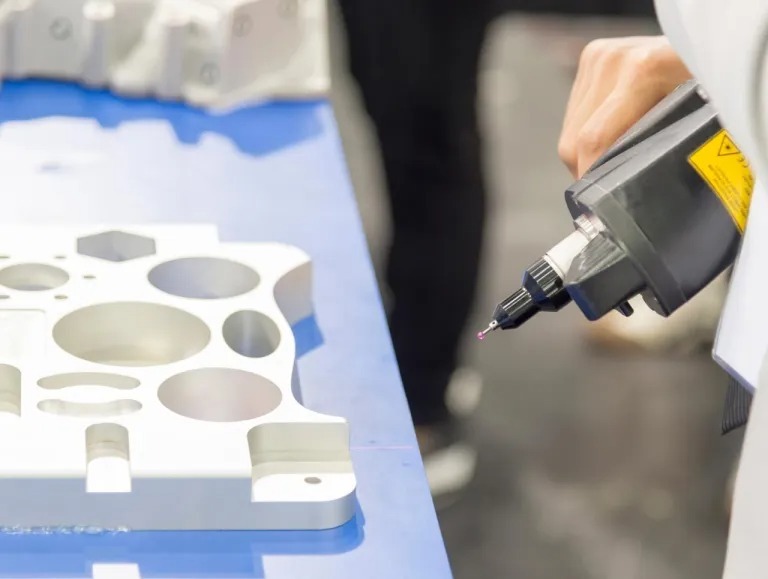

3D laser scanning in reverse engineering plays its crucial role in quality control, providing detailed measurements in the form of CAD files. These files are essential for manufacturing.

After reverse engineering is completed, CAD files become invaluable documentation for future use, forming the foundation for iterative design processes and comprehensive 2D prints.

Product Development:

3D laser scanning is a cornerstone in product development. By scanning prototypes and existing projects, designers can meticulously analyze prospective ideas, enabling crucial adjustments and improvements.

3D laser scanning not only provides detailed scans but also the opportunity to process the data into CAD files.

CAD files are needed for manufacturing including machining, laser cutting, injection molding, and other processes. Having a 3D parasolid allows for the computing systems to know exactly how to produce the file.

Reverse Engineering:

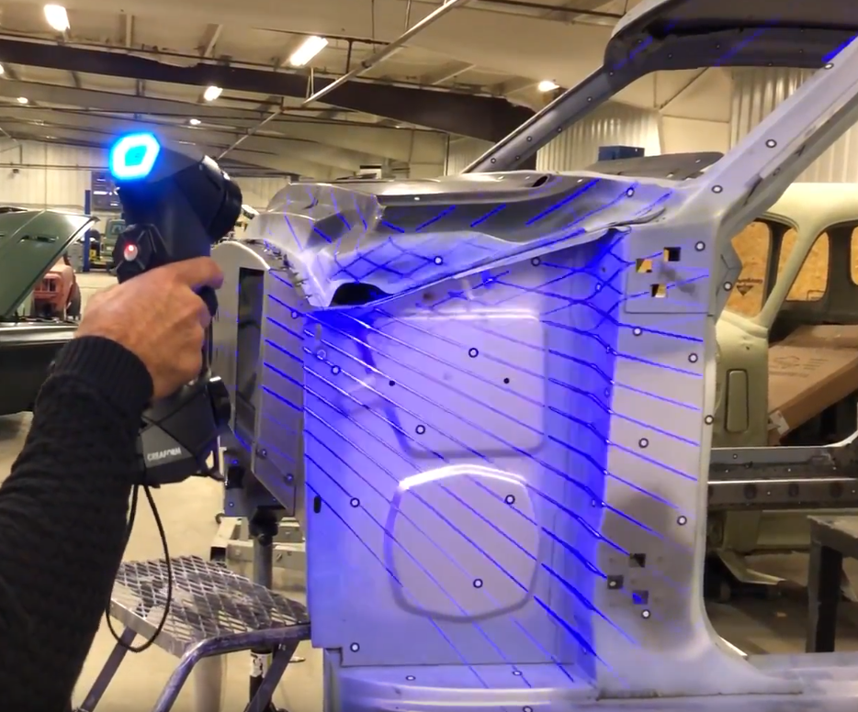

In many industries, reverse engineering is essential for recreating existing components, tools, or products.

3D scanning reverse engineering processes facilitate the delivery of highly precise measurements, including all features. The acquired CAD model can be adjusted and modified, allowing for the creation of entirely new products or enhancements to existing ones.

When creating working prototypes, the created CAD file is ready for as many design iterations as needed.

Quality Control:

Once a product design is complete, a thorough quality check becomes paramount before market release.

3D scanning provides detailed and accurate measurements, allowing for the examination of prototypes or small trial batches to ensure consistency and adherence to standards.

The resulting CAD files serve as valuable documentation for future use along with a 2D print to follow.

10 Industries for 3D Scanning Applications

3D scanning is employed across a diverse range of engineering industries, enhancing various processes and applications. Some specific engineering industries where 3D scanning finds extensive use include:

-

Aerospace Engineering:

In aerospace, 3D scanning is used for precision measurements, quality control, and reverse engineering of components, ensuring the accuracy and safety of aircraft structures.

-

Automotive Engineering:

Automotive engineers utilize 3D scanning for design, prototyping, and quality control of components, as well as for reverse engineering existing parts for improvements or modifications.

-

Civil Engineering:

In civil engineering, 3D scanning aids in surveying, topographical mapping, and monitoring structural integrity. It is also used for creating accurate as-built documentation.

Civil engineers would employ a long range 3D scanner. Specifically one that fits on a tripod. These allow for larger areas to be scanned but do not have the same precision as a laser scanner.

-

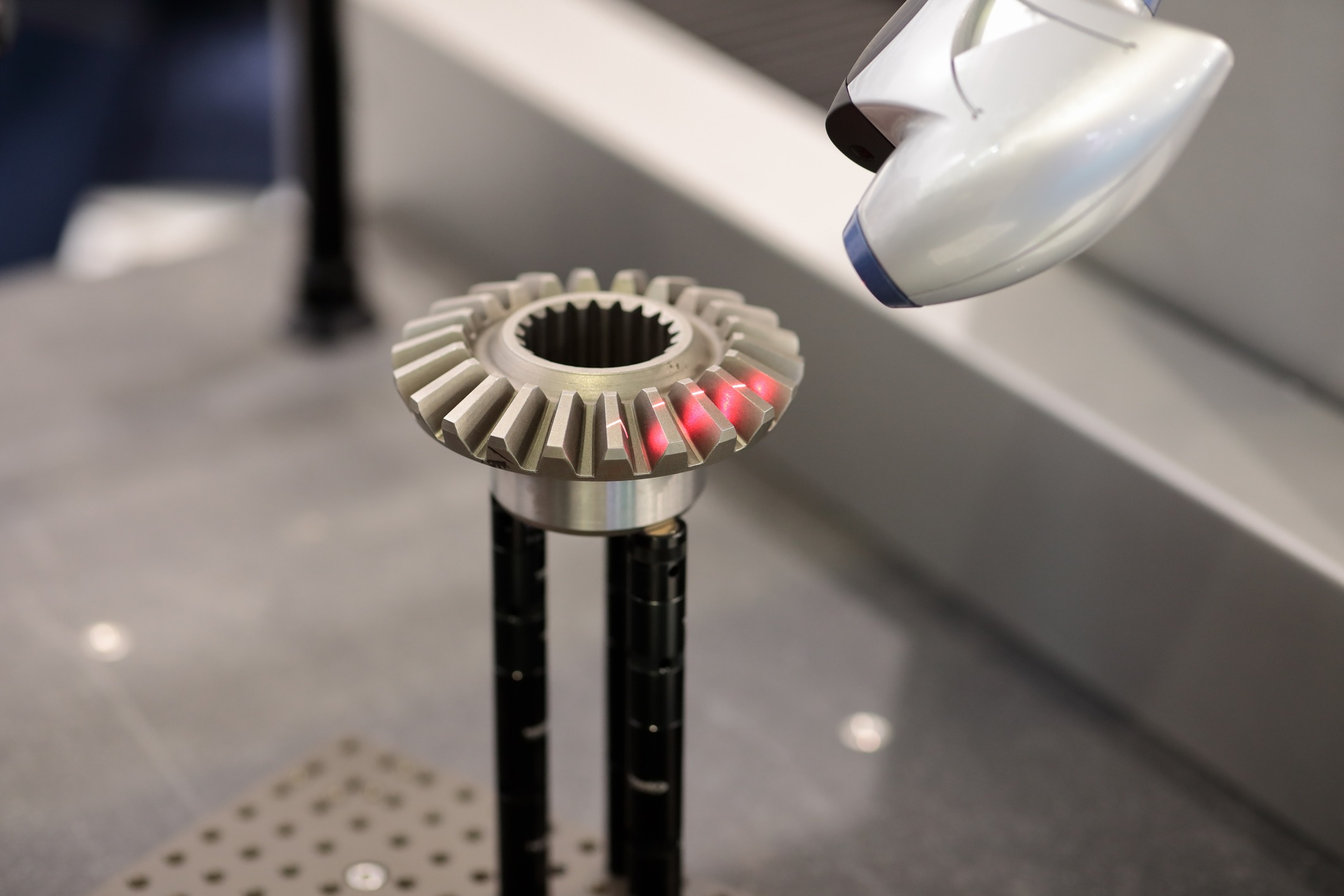

Mechanical Engineering:

3D scanning is integral to mechanical engineering for designing and validating prototypes, analyzing components for stress and strain, and optimizing the performance of machinery.

By using an ultra-precise 3D scanner, engineers can detect damage in parts that cannot be seen by the naked eye. -

Manufacturing Engineering:

In manufacturing, 3D scanning is applied for quality control, inspection of machined parts, and ensuring precise tolerances in the production of components for various industries.

CAD file creation from 3D scanning reverse engineering means the files created are extremely accurate. This delivers more profitability and less manufacturing time.

-

Architectural Engineering:

Architectural engineers utilize 3D scanning for creating accurate as-built models, site documentation, and monitoring construction progress, enhancing efficiency in architectural design and construction.

Architects will use the same type of scanner as civil engineers to create meshes of large areas.

- Biomedical Engineering:

How is 3D scanning important to biomedical industries? Detailed, anatomically correct allows for the creation of personalized medical devices, and facilitating advancements in prosthetics and implants. -

Electrical Engineering:

In electrical engineering, 3D scanning aids in the design and placement of components on circuit boards, ensuring optimal layouts and enhancing the efficiency of electronic systems.

These items are usually tiny in size, down to the millimeter yet easily detected by a 3D scanner.

-

Energy and Power Engineering:

3D scanning is applied in energy and power industries for inspecting and maintaining infrastructure, such as power plants and pipelines, as well as optimizing the design of energy-efficient systems.

-

Environmental Engineering:

Environmental engineers use 3D scanning for mapping and monitoring environmental features, such as terrain, water bodies, and vegetation, contributing to effective environmental planning and management.

These are just a few examples of engineering industries. The versatility of 3D scanning applications allows it to be applied in numerous other engineering disciplines, contributing to improved efficiency, accuracy, and innovation across the engineering spectrum.

The Future in 3D Scanning Applications

This comprehensive article explored the multifaceted applications of 3D scanning in the realm of engineering, transcending traditional boundaries and revolutionizing various industries.

Beginning with an overview of 3D scanning’s pivotal role in engineering, we delved into specific applications across diverse engineering disciplines.

From aerospace and automotive to civil, mechanical, and manufacturing engineering, 3D scanning proves instrumental in precision measurements, quality control, and reverse engineering, significantly enhancing efficiency in design and production processes.

The future of 3D scanning holds exciting prospects as it expands into diverse industries. In augmented and virtual reality, 3D scanning enhances realism, while in robotics, it aids in object recognition for improved automation.

Smart cities benefit from detailed digital twins created through 3D scanning, and the technology contributes to cultural heritage preservation. In fashion and retail, personalized designs and virtual try-ons may become more prevalent. Healthcare sees advancements in customized medical devices, while the entertainment industry utilizes 3D scanning for lifelike creations.

Education benefits from interactive lessons, and environmental monitoring gains precision in studying landscapes. Customized manufacturing and on-demand production may thrive through 3D scanning.

The technology’s adaptability and precision position it as a transformative force across various sectors, promising innovation and efficiency in the future.

Concluding Ideas of 3D Scanning Applications

In conclusion, this comprehensive exploration has shed light on the remarkable versatility and transformative impact of 3D scanning applications in the field of engineering and beyond.

From its fundamental role in precision measurements and quality control to its invaluable contributions in reverse engineering and product development, 3D scanning emerges as a cornerstone technology propelling efficiency across diverse engineering disciplines.

The article highlights its significance in aerospace, automotive, civil, mechanical, and manufacturing engineering, showcasing how this technology empowers professionals to streamline processes and innovate with unprecedented accuracy.

Moreover, as we gaze into the future, the article anticipates 3D scanning’s evolution into new frontiers. Its integration into augmented and virtual reality, robotics, smart cities, and personalized manufacturing signifies a paradigm shift in how we perceive and interact with the world.

From cultural heritage preservation to advancements in healthcare, education, and environmental monitoring, 3D scanning stands poised as a transformative force, promising innovation, efficiency, and precision across a myriad of industries.

In essence, the adaptability and precision of 3D scanning not only revolutionize engineering applications but also pave the way for a future where this technology becomes an indispensable tool in the hands of innovators, creators, and problem solvers across the vast landscape of human endeavor.

The journey of 3D scanning applications is one of boundless possibilities, where the fusion of technology and imagination continues to shape a future defined by accuracy, innovation, and efficiency.