Reverse engineering has become an essential part of today’s engineering workflows. Whether you’re restoring a legacy component, redesigning tooling, developing aftermarket upgrades, or creating manufacturing-ready CAD files from physical parts, having an accurate 3D representation is critical. Naturally, the question arises: “What is the best scanner for reverse engineering?”

It’s a fair question — but the real answer is more nuanced than simply choosing a device. Reverse engineering depends on far more than just hardware. Accuracy requirements, software capability, engineering expertise, CAD modeling skill, and environmental factors all determine the final quality of the reconstruction. This guide breaks down what makes a scanner suitable for engineering-level reverse engineering, compares the major technologies, and explains when it makes more sense to use professional reverse engineering services instead of purchasing costly equipment.

What Reverse Engineering Really Requires

Reverse engineering isn’t simply scanning an object and pressing “convert to CAD.” Engineers must extract both the literal geometry and the functional design intent — the features, symmetry, constraints, thicknesses, and surfaces that define how a part actually works.

To achieve this, the scanning process must be extremely accurate. Engineering-grade reverse engineering typically demands tolerances between 0.025 mm and 0.1 mm, depending on part size and application. The equipment must also be capable of producing dense data, stable results, and reliable repeatability, even on challenging materials like carbon fiber, cast metal, rubber, glossy surfaces, or deep pockets.

Finally, the workflow must integrate smoothly with CAD platforms such as SolidWorks, NX, CATIA, or Inventor. A “good” scanner should not simply capture data — it should support a complete engineering workflow from physical part to manufacturable CAD.

What Makes a Scanner Good for Reverse Engineering?

Several engineering factors determine whether a scanner is appropriate for reverse engineering:

-

Accuracy: The most important metric. Reverse engineering demands metrology-grade performance, not consumer-level scanning.

-

Speed: Engineers often need full part captures in minutes, not hours. High-end scanners collect millions of points per second.

-

Surface capability: A good scanner handles dark plastics, shiny metals, and curved surfaces without losing data.

-

Software compatibility: Professionals rely on tools like VXModel, Geomagic Design X, and PolyWorks — scanners must export clean, usable data.

-

Stability and repeatability: Engineering workflows require consistent measurement, even when the part is scanned multiple times or in different environments.

These are the benchmarks that separate hobby-grade scanners from those used in aerospace, manufacturing, and motorsports.

Scanner Categories and Their Engineering Uses

Not all 3D scanners are intended for the same purpose. Here’s how the primary categories compare when used for reverse engineering.

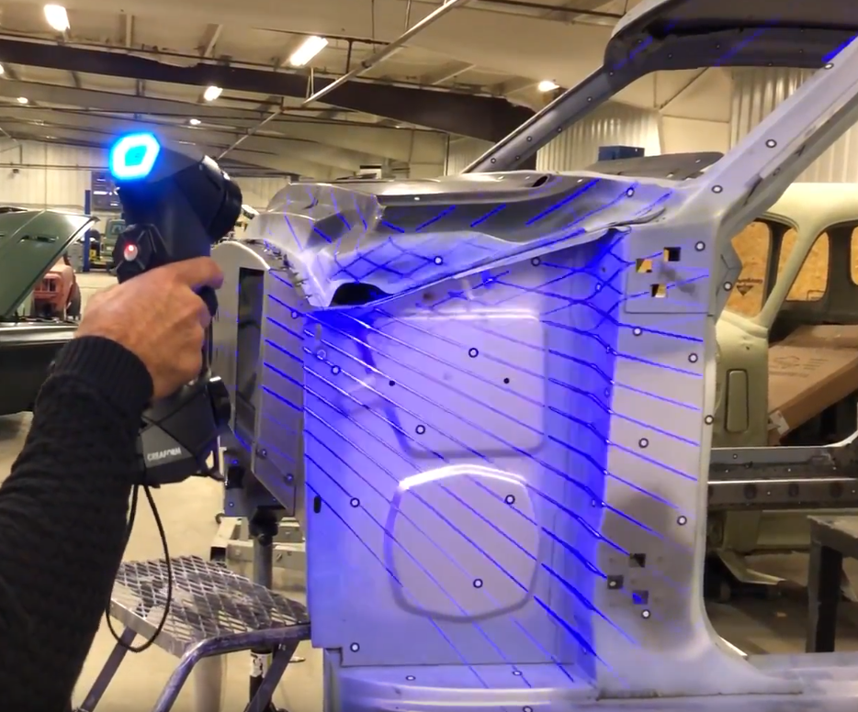

Metrology-Grade Handheld Laser Scanners (The Gold Standard)

For true engineering precision, metrology-level handheld laser scanners remain the industry benchmark. Devices like the Creaform HandySCAN BLACK Elite can achieve ±0.025 mm accuracy, making them suitable for everything from turbine components to automotive housings to race car aero parts. These scanners excel on complex surfaces, maintain strong volumetric accuracy, and are portable enough to use in-field or on-site.

They are fast, reliable, and extremely capable — which is why almost every professional reverse engineering firm uses them daily.

Structured Light Scanners

Structured light scanners project patterns instead of lasers. They can be effective for medium-sized parts and organic shapes but generally fall short when engineers need tight tolerances, work with reflective material, or require high stability. They are more affordable, but less versatile and less precise.

Long-Range Terrestrial Scanners

These tripod-based systems are designed for buildings, vehicles, rooms, and industrial environments — not mechanical parts. They work well for architectural documentation, as-builts, and facility scans but lack the accuracy needed for small or mid-sized reverse engineering applications.

Consumer / Budget Scanners

Low-cost scanners (such as smartphone LiDAR, Revopoint, or hobby-level devices) simply do not meet engineering tolerances. They are perfectly adequate for visualization or rough concept modeling, but not suitable for design, manufacturing, or precision engineering.

So What Is the Best Scanner for Reverse Engineering?

From a technical standpoint, the most capable and reliable devices for reverse engineering are metrology-grade handheld laser scanners, particularly those from the Creaform HandySCAN series or comparable professional systems. They provide the accuracy, portability, and surface performance needed for high-precision engineering work.

However — and this is important — owning the “best scanner” does not guarantee accurate reverse engineering results.

Reverse engineering is far more than scanning. The scanner is just the beginning.

Why Most Companies Should NOT Buy a 3D Scanner

Even though high-end scanners are incredibly powerful, purchasing one is often not the smartest move for most businesses — especially those that only need reverse engineering a few times a year.

Here’s why:

The Equipment Cost Is Extremely High

A high-end scanner suitable for engineering-level accuracy costs $60,000 to $120,000+ on its own. Once you add required accessories, calibration tools, tripods, targets, and workstations, the investment grows even larger.

Software Costs Add Thousands per Year

Reverse engineering relies heavily on specialized software such as Geomagic Design X, VXModel, or PolyWorks. These tools often cost $8,000 to $20,000 per year, and require significant training to use effectively.

Staff Training Takes Months (And You Risk Losing Them)

Even if you buy the equipment, a scanner is only as valuable as the person using it. Proper training includes:

-

Scan acquisition

-

Mesh cleanup

-

Feature extraction

-

Surface reconstruction

-

Assembly alignment

-

CAD skill

-

Design intent interpretation

Companies frequently invest months upskilling a technician — only to lose that individual later. The expertise walks out the door, while the scanner stays behind underused.

Reverse Engineering Is Mostly CAD, Not Scanning

Scanning is fast. CAD modeling is the real heavy lifting. Converting a mesh into a fully parametric, editable, manufacturable CAD model requires highly experienced engineers — often far more advanced than a typical in-house CAD designer.

Buying a scanner does not solve the engineering challenge.

Many Companies Only Need Scanning Occasionally

If your reverse engineering needs come up only a few times per year — for a failed tool, legacy part, or fitment study — the investment simply doesn’t justify the equipment cost, software licenses, and internal labor.

Why Hiring a Reverse Engineering Provider Makes More Sense

This is why many manufacturers, aerospace teams, automotive shops, and engineering departments turn to professional service providers instead of absorbing the cost and responsibility internally.

Partnering with an expert team like Tangent Solutions gives you access to:

-

Metrology-grade 3D scanning equipment

-

Certified scanning technicians

-

Senior CAD engineers specializing in reverse engineering

-

Scan-to-CAD workflows

-

Manufacturing-ready deliverables

-

Fast turnaround without internal staffing issues

You eliminate the cost of equipment, the time spent training staff, the risk of losing employees, and the complexity of maintaining a scanning program — while still receiving high-accuracy engineering results.

If your company would rather avoid a six-figure investment, outsourcing the work is by far the smarter choice. Our reverse engineering services provide everything needed for a complete digital reconstruction, from scanning to CAD modeling to inspection reports.

Industries That Benefit From Professional Reverse Engineering

A wide range of engineering-driven industries rely on reverse engineering to stay competitive:

Manufacturing

Companies recreate tooling, validate molds, inspect production runs, repair components, and keep critical legacy parts in service.

Aerospace

Aging aircraft frequently require replacement components with no existing CAD. Scanning helps rebuild accurate models while maintaining tight aerospace tolerances.

Motorsports & Automotive

Teams use reverse engineering for aero design, fitment studies, welding assemblies, bracket fabrication, and performance upgrades — often needing same-week results.

Defense

Military platforms rely heavily on reverse engineering to modernize components, integrate equipment, and support mission-critical repairs.

Industrial Engineering

Machinery, automation components, and large assemblies benefit from high-accuracy digital reconstruction during repair cycles and redesigns.

The need for accuracy unites all these industries — and professional providers deliver it without the burden of internal equipment ownership.

Choosing the Best Solution for Your Company

At the end of the day, the “best scanner for reverse engineering” depends on your resources and needs. If you require daily scanning, have a dedicated engineering team, and are ready to invest heavily in equipment and training, purchasing a scanner may make sense.

But for most companies, the more cost-effective, low-risk, and efficient option is to partner with a reverse engineering provider who already has:

-

The best equipment

-

The right software

-

The engineering expertise

-

The workflow

-

The experience

This approach eliminates the financial and operational burden while giving you accurate, fast, and dependable results every time.

Work With Tangent Solutions

Tangent Solutions provides professional reverse engineering services using metrology-grade scanners and experienced CAD engineers who specialize in complex reconstruction. Whether you need a small precision part digitized, a full assembly modeled, or ongoing engineering support, we deliver accurate digital files ready for manufacturing.

If you’re considering purchasing an expensive 3D scanner — contact us first. We can help you evaluate your needs and determine whether outsourcing makes more sense for your business. Most of the time, it does.