If you work in manufacturing or product design, your company has likely made use of 3D scanning for its efficiency and usefulness. However, you may be wondering how fast 3D product scanning is, and the kind of turnaround you can expect.

The answer depends upon the type of scanner you use, the object being scanned, and more. Here’s some information on how fast 3D scanners can work, and how long you can expect to wait before getting your scan data results!

What Is 3D Scanning?

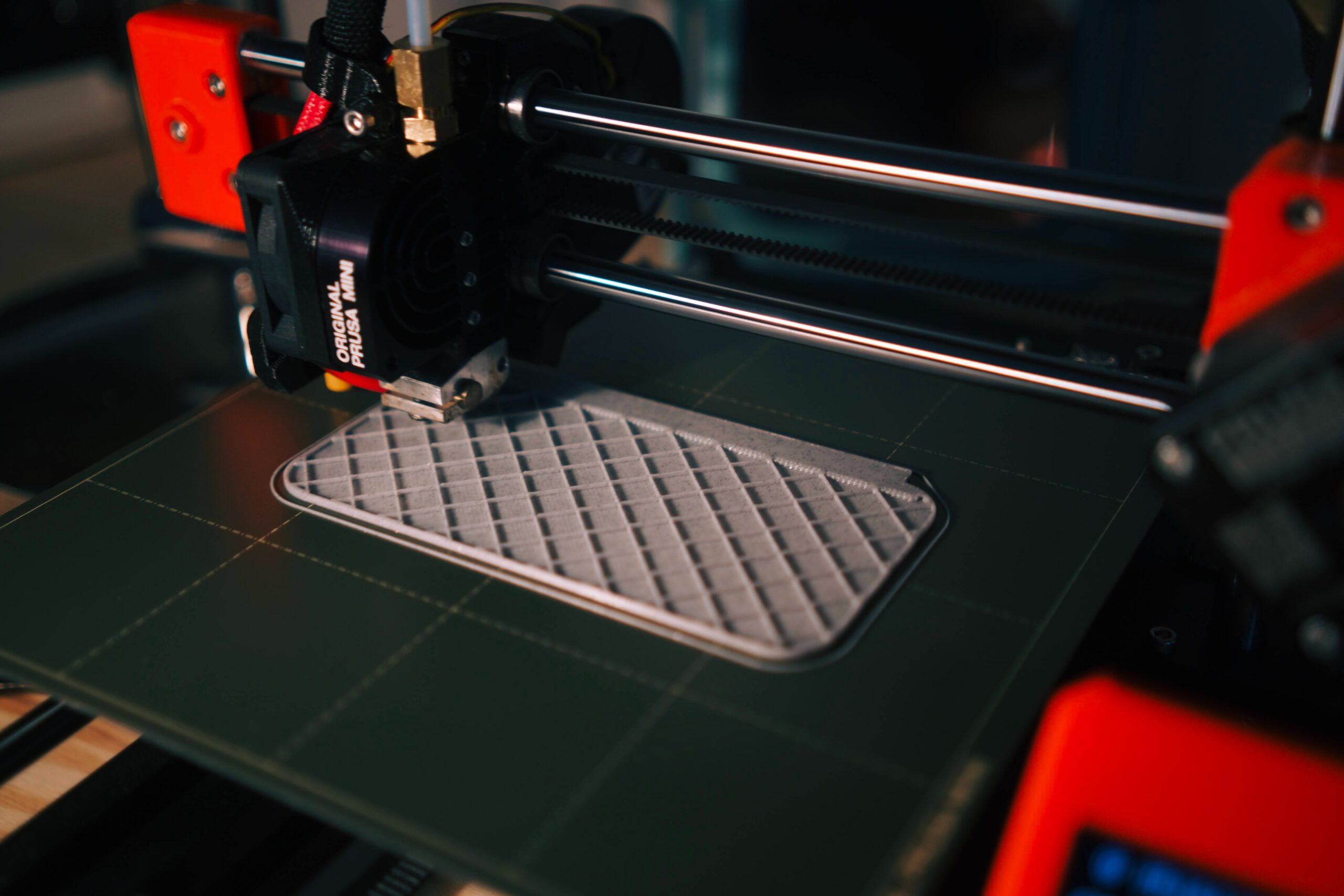

3D scanning, much like traditional scanning, takes images of a given object. However, 3D scanning takes many images from multiple angles and creates millions of data points that form the shape of the original object.

We use both lasers and structured light to capture the data about these objects. Thorough 3D scanning often takes multiple passes to include all the details, depending on the size and complexity of the object.

Even after an item is scanned, it often takes scanning companies time to compress data, render it into a CAD model, and accommodate other requests.

How Long Does 3D Scanning Take?

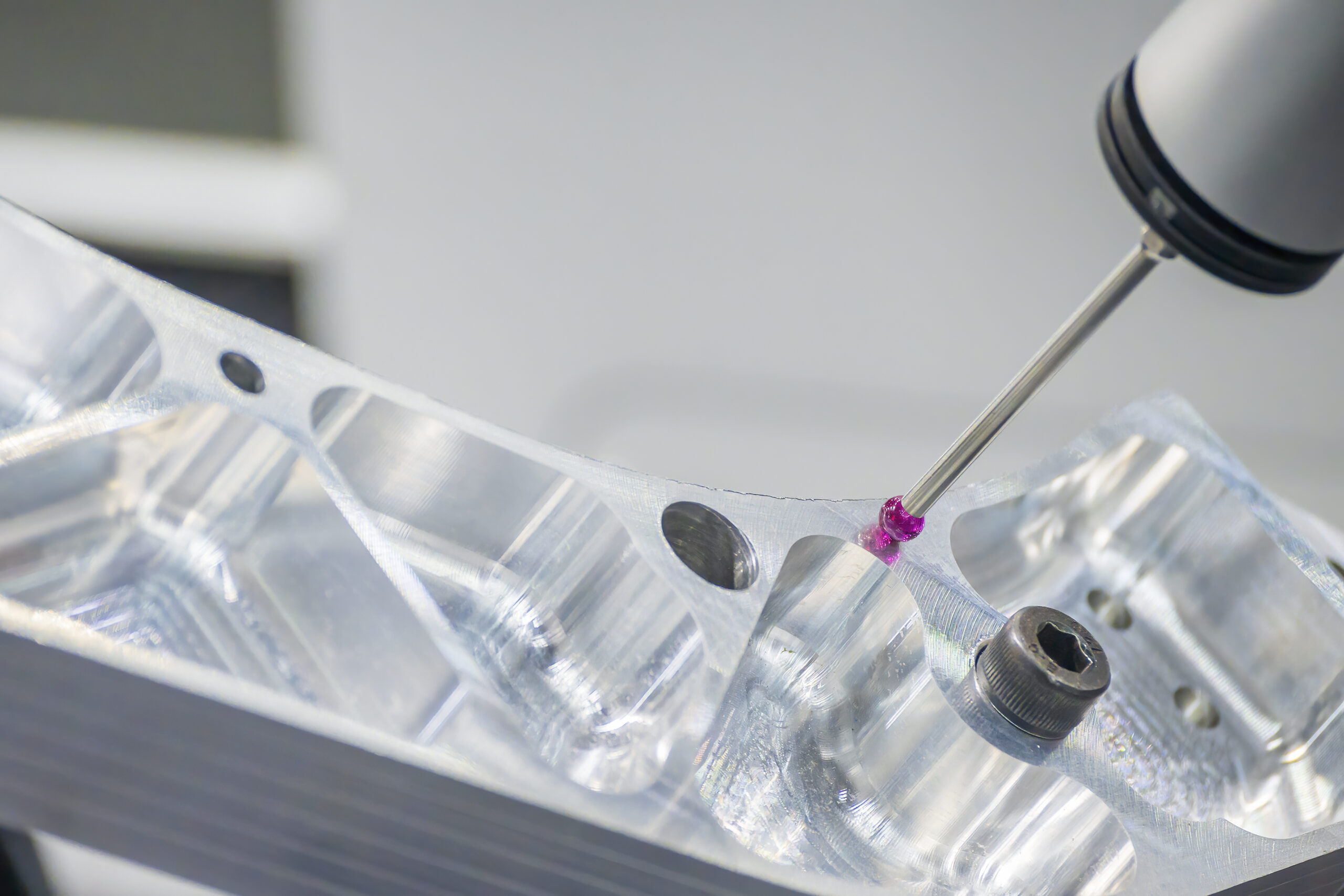

Every project is different, so scanning time can vary quite a bit. In general, the scanning itself takes somewhere between half an hour to several hours.

The final count depends upon the size of the item, how many details it has, and the item’s shape. A larger, more complex item will take more time to scan simply due to the surface area and level of detail.

The first scan usually lays the groundwork for the basic shape and size. Additional scans will add detail and increase the accuracy of the final outcome.

We’re ready to scan most items on the day they arrive at our facility, and we can send the data promptly and return your prototype without delay. Before we send the data, we always clean it up so that you can create a polished rendering when you’re ready to use it.

What Data Processing Options Are Available?

We can send you the raw mesh data, clean up the mesh before sending it, or even render it on your behalf. Fully rendered data is ready to use in CAD software. We can send the data in any file type, according to your preference.

Our team can also compress data. 3D scans are very large, and rendering them can be a slow process due to the file size.

When we deliver rendered data, you save time and receive crisp files with the details you need. We’ll make sure the results are perfectly shaped, without any jagged edges or holes.

3D models are incredibly useful for engineering purposes and as a way to introduce new products before you’re able to make a prototype. It’s a way to provide detailed information and visuals on your product before you take the next step in creating it.

The team at Tangent Solutions provides 3D scanning and several related services, including rendering, reverse engineering, and rapid prototyping. We help companies realize their visions and get the benefits of 3D scanning without needing to purchase the equipment themselves.