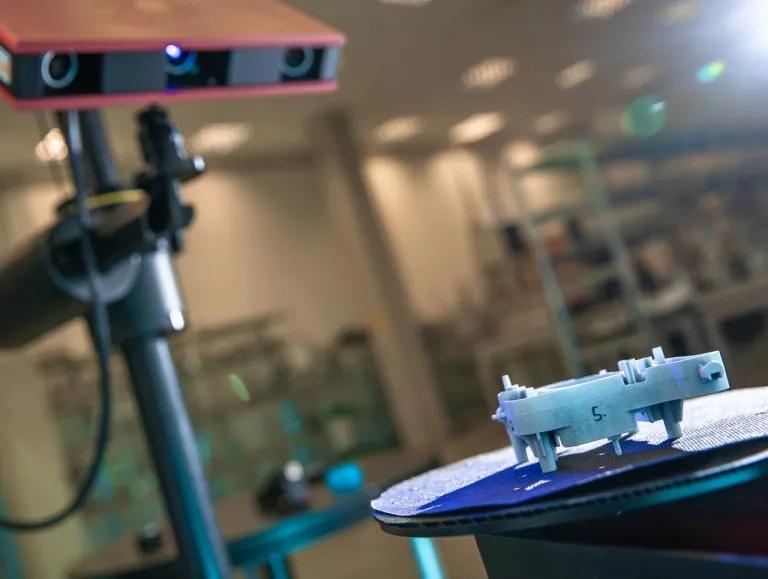

What Is 3D Laser Scanning? A Complete Engineering Guide.

3D laser scanning has become one of the most valuable tools in modern engineering. Whether you’re designing parts, validating tolerances, reverse engineering legacy components, or capturing complex geometry that would be impossible to measure manually, laser scanning delivers speed, accuracy, and repeatability that traditional measurement can’t match. But what exactly is 3D laser scanning? How […]

The Best Scanner for Reverse Engineering: An Engineering-First Guide

Reverse engineering has become an essential part of today’s engineering workflows. Whether you’re restoring a legacy component, redesigning tooling, developing aftermarket upgrades, or creating manufacturing-ready CAD files from physical parts, having an accurate 3D representation is critical. Naturally, the question arises: “What is the best scanner for reverse engineering?” It’s a fair question — but […]

How Long Does 3D Scanning Take?

Understanding The Process, Speed, And Turnaround Time If you work in manufacturing, product design, or engineering, you’ve likely seen how powerful 3D scanning can be. It’s an essential tool for capturing precise measurements, accelerating development, and converting real-world objects into digital models. But one of the most common questions we hear is: how long does […]

Why You Should Outsource CAD Design — and How It Accelerates Product Development

In the product development landscape, companies face increasing pressure to deliver faster, more accurate designs without inflating overhead. Maintaining a full in-house CAD department is costly — salaries, benefits, software, hardware, and training can quickly drain resources. That’s why many organizations now outsource CAD design to trusted engineering partners. Outsourcing allows teams to access experienced […]

Outsource 3D Scanning: How to Accelerate Product Development Without Adding Overhead

Modern product development moves fast — and companies that can rapidly capture, convert, and deploy 3D data gain a major advantage. But building and maintaining an in-house scanning operation isn’t always practical. Between costly equipment, operator training, calibration, and software, the overhead often outweighs the benefits. That’s why many engineering and manufacturing teams now choose […]

Why Your Business Should Be Using 3D Scanning Technology

Are you looking to incorporate 3D scanning technology services into your business? In the competitive industries of engineering and manufacturing, precision, speed, and efficiency are no longer optional — they’re essential. Companies that adopt cutting-edge tools early often set the standard in their industries. One of the most impactful of those tools is 3D scanning […]

How 3D Laser Scanning Converts Real-World Parts Into CAD Models

Introduction to Laser Scanning In today’s competitive world of product development, companies need to turn ideas into reality faster and more accurately. Traditional measuring methods often struggle to capture the exact shape of complex parts. This is especially true for older components that do not have documentation or CAD models. 3D laser scanning is a […]

5 Ways Product Engineering Can Accelerate Your Go-to-Market Strategy

Instead of designing, you should be working on your business. Outsourcing product engineering tasks—from initial CAD design to prototyping and production—offers numerous advantages. The possibility of creating a product line is easier than ever with globalization. Manufacturing costs have decreased, and access to overseas supplies has improved, leading to better product margins. Modern design and […]

Case Study: On-site, Large Format 3D Scanning for Bayliss Machine & Welding

Client: Bayliss Machine & WeldingLocation: Birmingham, AlabamaServices: Mobile 3D Scanning, Reverse Engineering, 2D Print Creation Overview Tangent Solutions specializes in large-format 3D scanning, reverse engineering of legacy parts, and on-demand CAD support. Our team travels across the U.S. offering fully mobile 3D scanning services —making it easy to support clients in the field, shop, or […]

Why More Companies are Using Reverse Engineering in Manufacturing

In today’s fast-paced manufacturing environment, many companies are turning to reverse engineering in manufacturing to regain control over their product data, streamline production, and shorten development timelines. Whether you’re a manufacturer who no longer has original CAD files or an engineer dealing with product variations introduced during overseas production, reverse engineering can provide an accurate […]