Across manufacturing, aerospace, automotive, motorsports, consumer products, and industrial engineering, one technology has become critical to accurate design, quality control, and reverse engineering: 3D scanning. As more companies work to modernize their workflows, reduce measurement time, and eliminate design guesswork, many find themselves asking whether they should invest in their own scanner or instead hire a 3D scanning company.

At first glance, buying a scanner may seem appealing, especially with the growing availability of handheld devices. But professional-grade scanning is far more than pointing a device at a part and generating a mesh. The true value lies in the accuracy, the experience of the operator, the calibration of the equipment, the software ecosystem, and the final data quality that determines whether a scan is usable for engineering purposes.

This guide explains what 3D scanning actually involves, the cost and complexity behind an in-house setup, the advantages of hiring a scanning provider, and how outsourcing can dramatically improve speed, accuracy, and overall engineering quality.

Understanding What 3D Scanning Actually Is

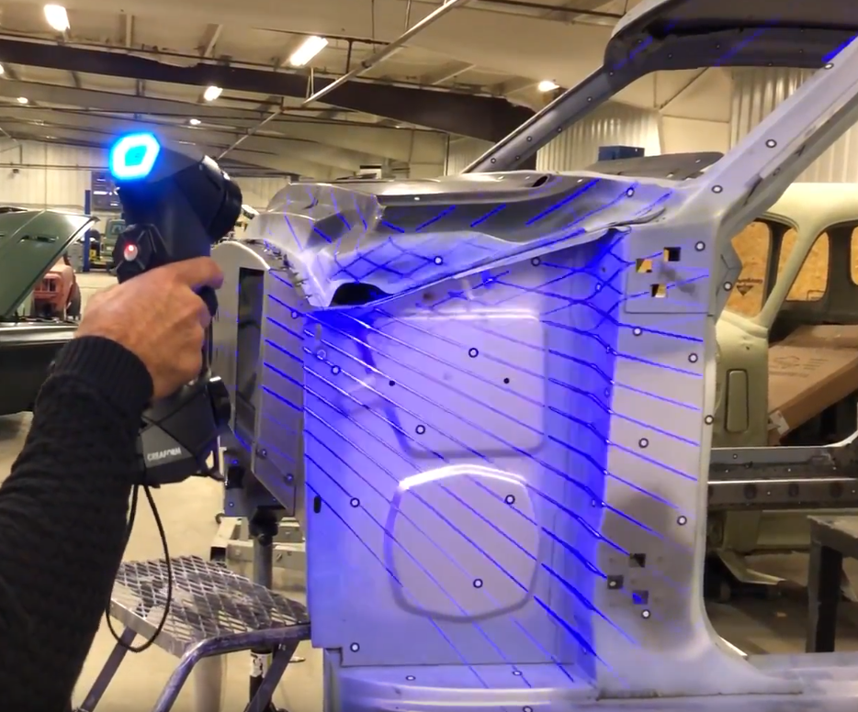

3D scanning is the process of capturing the physical geometry of an object or environment with extreme precision. Professional scanners project laser lines or structured light patterns over surfaces and record millions of data points per second. The result is a high-resolution point cloud or mesh that represents the shape, curvature, features, and contours of the original object.

For engineering applications, these scans must meet tight tolerances. Manufacturing engineers rely on high-accuracy scans for reverse engineering, tool validation, fixture design, part inspection, and digital archiving. Aerospace and motorsports engineers use scanning to evaluate fitment, redesign components, and verify compliance with strict dimensional requirements.

Because 3D scanning digitally captures full surfaces instead of just a few measurement points, engineers gain visibility into complex shapes that are impossible to measure manually. This dramatically speeds up design iterations and eliminates errors that occur when assumptions are made about geometry.

Why Companies Consider Buying Their Own Scanner

It is common for engineering teams to initially explore purchasing a scanner when they realize how much faster scanning is compared to manual measurement. The idea of having scanning equipment in-house sounds convenient. Being able to scan prototypes, test parts, worn components, or competitor products at a moment’s notice seems like it would accelerate development.

And it will—if the scanner is the right type, the operator is trained properly, the software is integrated, and the engineering team has the skills to convert the scan data into usable CAD. But these prerequisites carry substantial cost and complexity.

Before committing to buying a scanner, companies need to understand everything that is required behind the scenes to produce accurate, engineering-ready results.

The Hidden Costs of In-House 3D Scanning

Purchasing a scanner is rarely a simple equipment decision. Reverse engineering and scan-based workflows rely on several layers of hardware, software, and expertise. Each of these carries a cost, and when taken together, the investment becomes significant.

First, the scanner itself is expensive. A metrology-grade scanner suitable for engineering applications often costs between $60,000 and $120,000. Lower-cost scanners do exist, but they lack the precision, stability, and volumetric accuracy required for manufacturing, aerospace, motorsports, and defense work.

Next, there is the software. Reverse engineering tools such as VXModel, Geomagic Design X, or PolyWorks come with annual licensing fees that can reach into the tens of thousands. These programs are powerful but require hands-on experience and technical understanding to use effectively.

Then there is training. Scanning is easy to start—but difficult to master. The operator must understand how to handle reflective surfaces, deep pockets, complex curvature, alignment strategies, part fixturing, calibration, drift control, and noise reduction. A poorly trained operator can easily produce inaccurate scans, even with a high-end scanner.

Finally, there is staff retention. Many companies invest heavily in training employees to become proficient at scanning and mesh processing, only to lose them later. When that happens, the company is left with expensive equipment but no one who knows how to use it to its full potential.

All of this leads many companies to a more practical conclusion: it is often far more efficient to hire a 3D scanning company rather than attempt to build a scanning department from the ground up.

Why Hiring a 3D Scanning Company Makes More Sense

Professional scanning providers eliminate the cost and complexity of owning metrology equipment while delivering results that meet engineering and manufacturing tolerances. For many teams, outsourcing is not just easier—it is the only way to achieve the precision required for high-performance applications.

When you work with an experienced scanning provider, you gain access to high-end equipment without purchasing it. Professional scanners deliver accuracy in the 0.025 mm range, capture clean data across challenging surfaces, and maintain stable tracking even on large assemblies. These are capabilities that lower-cost devices simply cannot match.

Another major advantage of hiring a scanning provider is the expertise of the operator. Skilled scanning technicians understand how to prepare surfaces, manage reflections, align passes, minimize drift, and optimize scan coverage. They know how to interpret engineering requirements and adjust scanning strategy accordingly.

Just as important is what happens after scanning. Raw scan data is rarely usable as-is. A professional company handles the entire data-processing workflow, from noise cleanup to mesh optimization to alignment and scaling. The final deliverables come in forms that your engineering team can use immediately.

Tangent Solutions provides comprehensive 3D scanning services that include raw mesh delivery, cleaned mesh models, high-resolution point clouds, inspection reports, and scan-to-CAD packages. This gives engineering teams everything they need in a format that integrates directly into downstream design and manufacturing workflows.

How Professional 3D Scanning Improves Engineering Workflows

Outsourcing 3D scanning creates a noticeable improvement in engineering productivity and overall product quality. Instead of relying on manual measurements, partial drawings, or outdated CAD files, engineers receive detailed surface geometry captured with a high level of accuracy.

This is especially valuable during product development. Engineers can rapidly test iterations, compare designs to prototypes, and verify fitment before tooling or machining. When redesigning a part, having the original geometry captured precisely allows CAD engineers to focus on the functional improvements instead of reconstructing basic shapes.

Industries such as aerospace and motorsports benefit greatly from this accuracy. These fields require parts to fit seamlessly within tight tolerances. Even small deviations can affect performance, safety, or structural integrity. High-resolution scans eliminate ambiguity and reduce the chance of costly rework.

Manufacturing operations also gain advantages from professional scanning. Tooling, fixtures, and molds wear over time. Scanning these components allows companies to recreate or modify them without restarting the design process. Quality control teams can also compare production parts to nominal geometry to ensure consistency.

By choosing to hire a 3D scanning company, organizations gain immediate access to these capabilities without investing in equipment or training.

Examples of How Companies Use 3D Scanning Providers

Across industries, companies use professional scanning in different ways depending on their needs.

Aerospace manufacturers use scanning to verify complex surfaces, evaluate composite structures, and develop replacement components for legacy aircraft. Automotive and motorsports teams rely on scanning for aerodynamic components, chassis modifications, roll cage fitment, and high-precision part development. Manufacturers use it to validate tooling, inspect worn components, and reverse engineer discontinued parts.

Consumer product companies leverage scanning to accelerate prototype development, verify ergonomic shapes, and maintain consistent design language across product families. Industrial teams scan machinery and equipment to modernize components or create digital twins for maintenance planning.

Even companies that perform engineering in-house often prefer to outsource scanning because it ensures accuracy from the start of the project.

What You Get When You Hire a Professional Scanning Provider

When you hire a professional 3D scanning company, you gain access to equipment, expertise, and workflows that have been refined over hundreds or thousands of projects. Companies like Tangent Solutions deliver scan data that is accurate, clean, and ready to use.

A complete scanning service typically includes:

-

Same-day scanning for most parts

-

High-resolution raw mesh or point cloud

-

Cleaned and aligned mesh files

-

Scaled and validated data

-

Optional scan-to-CAD modeling

-

Engineering-ready deliverables

If needed, the provider can also produce fully parametric CAD models, mating features, assemblies, drawings, and manufacturing documentation.

Because these services are delivered by trained experts using high-end scanners, the results are reliable and consistent. Your engineering team can immediately begin working with the data rather than spending time cleaning it or questioning its accuracy.

When You Should Hire a 3D Scanning Company Instead of Buying a Scanner

Hiring a scanning firm is the best option when:

-

You only need scanning a few times per year.

-

You do not want to invest in expensive hardware and software.

-

You want metrology-grade accuracy.

-

You lack the internal staff or training.

-

Your parts involve complex surfaces or high tolerances.

-

You need scan-to-CAD, inspection, or reverse engineering support.

In all of these cases, outsourcing provides better results at a fraction of the cost.

Work With Tangent Solutions

If your company is evaluating whether to buy equipment or hire a scanning provider, consider the full picture. Owning a scanner requires significant investment, training, and maintenance. Hiring professionals, on the other hand, gives you immediate access to accurate scans, experienced technicians, and engineering-ready data.

Tangent Solutions offers comprehensive 3D scanning services using metrology-grade scanners and certified technicians. We help companies across manufacturing, aerospace, motorsports, automotive, and industrial engineering capture accurate geometry and produce reliable data for design, reverse engineering, inspection, and production.

Whether you need a one-time scan or ongoing engineering support, we can help. Contact us today to schedule a project and experience the speed and accuracy of professional scanning.