3D laser scanning is one of the best ways to gather ultra-precise data for an engineering project.

However, how much does 3D scanning cost? Is it an affordable service?

If you’re considering utilizing 3D scanning services for your project, you are wondering the price of 3D scanning costs and what factors go into the various prices for this service.

In today’s rapidly evolving technological landscape, 3D laser scanning has gained immense popularity across various industries. It offers a versatile and accurate method of capturing three-dimensional data, revolutionizing fields such as engineering, architecture, manufacturing, and quality applications.

In this article, we will delve into the factors that impact 3D scanning costs, including the size of the project, level of detail required, types of files needed, the quantity of objects to be scanned, and additional services or requirements.

What is 3D Laser Scanning?

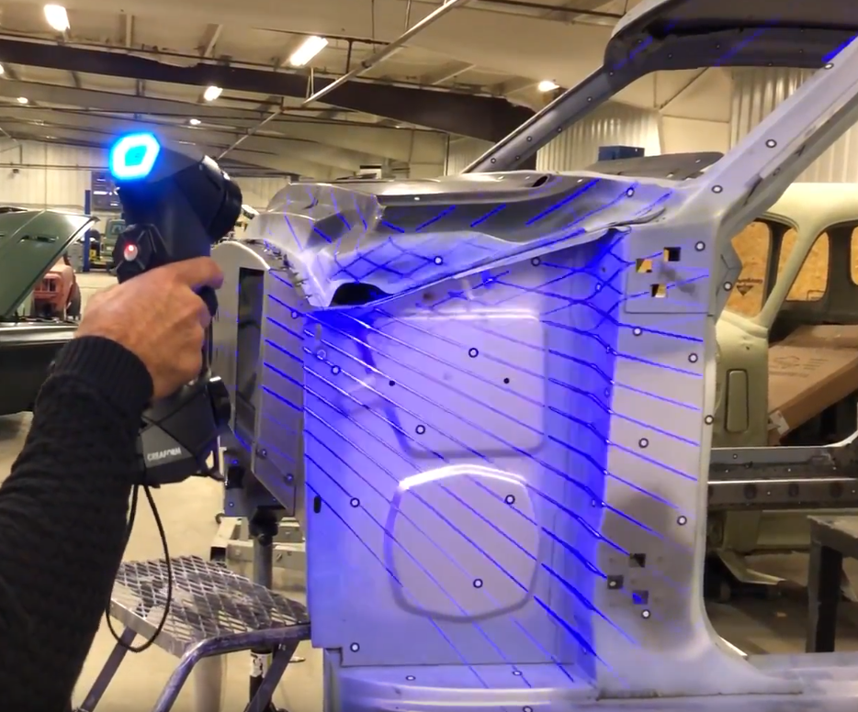

3D laser scanning is the process of capturing the shape, size, and geometry of real-world objects with immense amounts of detail, to create a digital 3D representation.

At its core, 3D laser scanning employs laser beams emitted from the scanner device to bounce off the surfaces of objects or environments being scanned. These lasers are meticulously controlled and directed, allowing them to sweep across the object’s surface and record millions of data points within seconds.

The distance and angles at which the laser beams strike the object are measured with extreme precision, resulting in a point cloud—a vast collection of individual data points that precisely define the object’s external and internal geometry.

The data created during 3D laser scanning can be turned into CAD models, the process of mesh to CAD conversion, which are essential for manufacturing and quality control applications. The latest 3D laser scanners can collect data up to 0.020mm in resolution.

Industries Using 3D Laser Scanning

3D laser scanning is a cutting-edge technology that revolutionizes the way we capture and replicate real-world objects and environments. It involves the use of highly advanced laser scanning equipment to meticulously record the shape, size, and intricate geometry of physical objects and spaces with an extraordinary level of precision.

This process results in the creation of highly detailed and accurate digital 3D representations, offering numerous applications across various industries.

- Manufacturing:

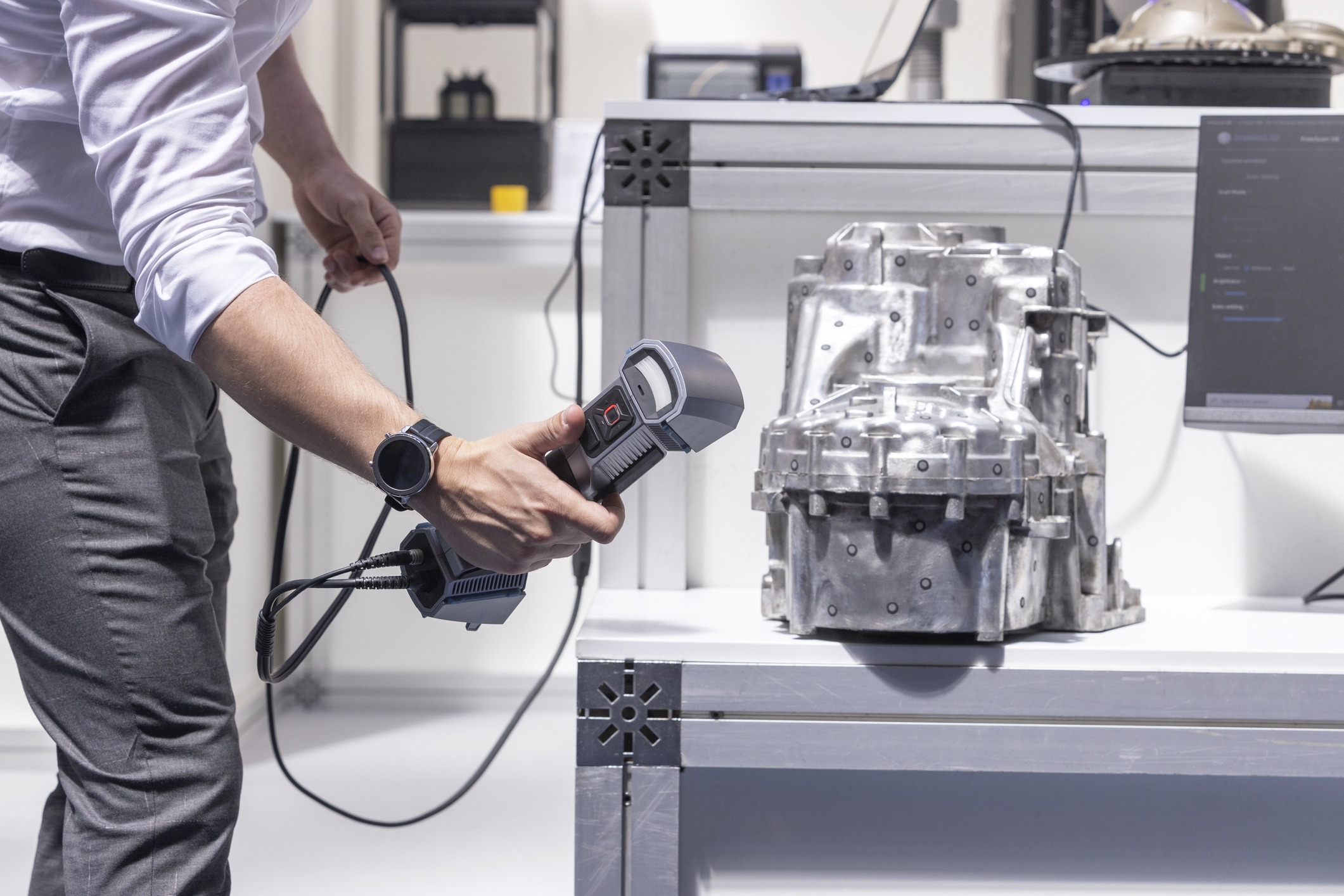

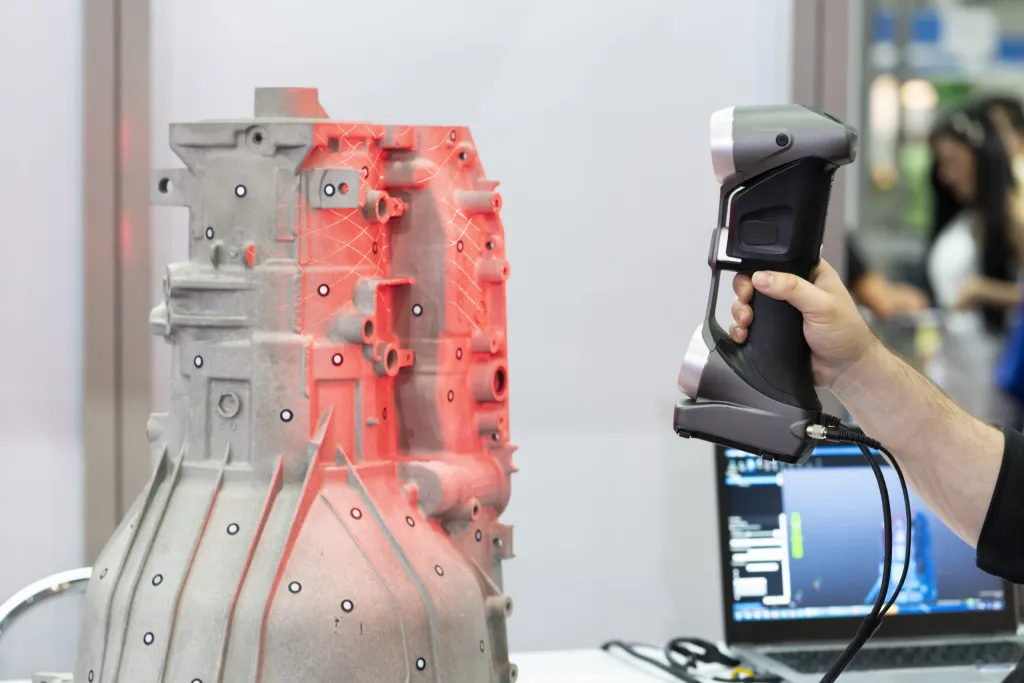

3D laser scanning plays a pivotal role in manufacturing processes. Manufacturers can scan physical prototypes or components and use the resulting 3D models as references for designing and refining products. This allows for the identification of any deviations from the intended design, enabling adjustments and improvements to be made.Additionally, these models serve as essential tools for creating molds, dies, and other manufacturing equipment, streamlining the production process and enhancing overall product quality.

This allows for the identification of any deviations from the intended design, enabling adjustments and improvements to be made.Additionally, these models serve as essential tools for creating molds, dies, and other manufacturing equipment, streamlining the production process and enhancing overall product quality. - Quality Control:

Maintaining product quality is paramount in various industries, and 3D laser scanning is instrumental in this regard. By comparing scanned objects or parts to their CAD models, manufacturers can meticulously inspect and measure them for discrepancies or defects.This technology is particularly valuable for identifying even the tiniest imperfections, ensuring that products meet strict quality standards. - Reverse Engineering:

In scenarios where CAD models are not available or need to be recreated, 3D laser scanning is a powerful tool for reverse engineering.It allows engineers to create accurate digital representations of existing physical objects, helping them understand the original design and replicate it for various purposes, such as reproducing obsolete parts or improving existing products.

- Architecture and Construction:

In architecture and construction, 3D laser scanning aids in capturing as-built conditions of existing structures or sites. Architects and engineers use the data to create precise models for renovation or retrofitting projects.It also helps in clash detection, where potential conflicts between new designs and existing structures are identified early, reducing costly errors during construction.

Factors of 3D Scanning Costs

There are several factors to consider when employing 3D scanning services.

This includes the size of the project, level of detail required, types of files needed, the quantity of objects to be scanned, additional services or requirements, geographic location, turnaround time, and the expertise and reputation of the service provider.

These factors contribute to the complexity, time, resources, and specialized equipment required for the scanning process, ultimately impacting the overall cost.

Below is an explanation of each of these factors and what to consider.

Size of the Project

The size of the project plays a significant role in determining the cost of 3D scanning. Larger objects, such as industrial machinery, buildings, or vehicles, require more time, effort, and resources to scan accurately.

The complexity of scanning larger objects often involves using advanced equipment and multiple scanning sessions to capture the complete geometry. Lifts, ladders, and scaffolding may be needed to reach these geometries.

Additionally, larger objects may require specialized handling and transportation arrangements, contributing to the overall cost. The size of the project not only affects the scanning time and equipment requirements but also impacts post-processing and data management.

Thankfully, our company Tangent Solutions scans at either half-day or full-day rates. This means no matter the size or quantity, only time reflected upon the scanning quote. Mobile scan services are ideal for large and remote project locations.

Level of Detail Required

The level of detail needed in the 3D scan is another crucial factor affecting the cost. Some applications, such as visual effects in the entertainment industry or product design in manufacturing, demand high-resolution scans with intricate details, such as fine textures or small features.

Achieving greater detail may require more time during the scanning process. It is a misconception that the larger the project, the more time-extensive.

This is not the case. Sometimes the smaller, more detailed projects ask for a technician to take their time while also performing the scanning process more than once.

You will need to think of the project goals when discussing 3D scanning cost. Do you require high tolerances like for aerospace parts? Or is your margin of error larger?

These methods can significantly impact the overall cost of the 3D scanning process. It is essential to determine the necessary level of detail to balance precision and budget requirements.

Types of Files Needed

Depending on your project’s specifications and intended applications, you may require different file formats, such as STL, OBJ, or CAD files.

Each format serves specific purposes and may involve additional post-processing steps to optimize the data for your particular application.

For example, if the scanned objects need to be integrated into CAD software for further modeling or engineering analysis, reverse engineering steps are required to convert the raw scan data into a usable format.

The complexity of generating these files, along with the required software and expertise, can impact the overall cost of the 3D scanning process.

Quantity of Objects to be Scanned

How many items do you need 3D scanned? Does your part need to be disassembled?

Scanning a single object may have a different cost structure compared to scanning multiple objects within a project.

Service providers may offer discounted rates for scanning larger quantities of objects, making it cost-effective to scan multiple items simultaneously.

However, the quantity of objects can also impact scanning time, data management, and post-processing efforts, so it’s crucial to consider the trade-off between cost savings and project timelines.

Additional Services and Requirements

Beyond the core 3D scanning process, additional services and requirements can impact the overall cost. These may include post-processing, data analysis, mesh optimization, or reverse engineering.

Post-processing tasks such as data cleaning, alignment, and merging multiple scans will need to be performed in the 3D scanner’s native software.

However, if your project requires specific deliverables like CAD models, you can choose to take the post processed data and perform this yourself. In most cases, reverse engineering is done in-house as most are not experienced in the mesh to CAD file conversion.

It is crucial to discuss your project requirements to get a comprehensive understanding of the additional services and their associated costs.

Want to see the difference between mesh and CAD files? Take a look at our Sample Folder to see common file deliveries.

Geographic Location

The geographic location of the 3D scanning service provider can also affect the cost. Prices may vary depending on the region or country where the service is being provided. Factors such as local labor costs, overhead expenses, and market demand can contribute to price discrepancies.

For remote jobs, mobile 3D laser scanning can be beneficial especially for projects that are not moveable. With our company, a technician arrives with only needing access to power and can scan any size object; from semi-trucks to boats.

Turnaround Time

The turnaround time required for the 3D scanning project can impact the cost. If you have a tight deadline or require expedited services, the service provider may need to allocate additional resources or adjust their schedule to accommodate your project.

Rush orders or fast-track services often come at a premium price due to the prioritization and additional effort required. It’s advisable to discuss your timeline expectations with the service provider in advance to determine any associated cost implications.

Expertise and Reputation of the Service Provider

The expertise and reputation of the 3D scanning service provider can also influence the cost. Well-established and reputable providers with a track record of delivering high-quality results may charge higher rates compared to less experienced or less recognized providers.

Choosing a reliable service provider ensures that you receive accurate scans, professional guidance, and reliable post-processing services. While opting for a reputable provider may come at a higher cost, it can provide peace of mind and minimize the risk of costly reworks or unsatisfactory outcomes.

3D Scanning Costs Conclusion

Understanding the factors that contribute to 3D scanning costs is crucial for effective project planning and budgeting. The size of the project, level of detail required, types of files needed, the quantity of objects to be scanned, additional services or requirements, geographic location, turnaround time, and the expertise and reputation of the service provider are all important considerations.

By carefully assessing these factors and working with reputable 3D scanning service providers, you can ensure that your project meets its objectives while staying within your budgetary constraints.

It is advisable to obtain multiple quotes from different service providers, compare their offerings, and consider the value they provide in terms of quality, expertise, and reliability.

Remember, the initial 3D scanning cost is an investment in obtaining accurate and detailed data, enabling you to make informed decisions and unlock new possibilities in your industry. So, evaluate your project requirements, consult with experts, and make an informed decision that aligns with your goals. With 3D scanning, the possibilities are endless.