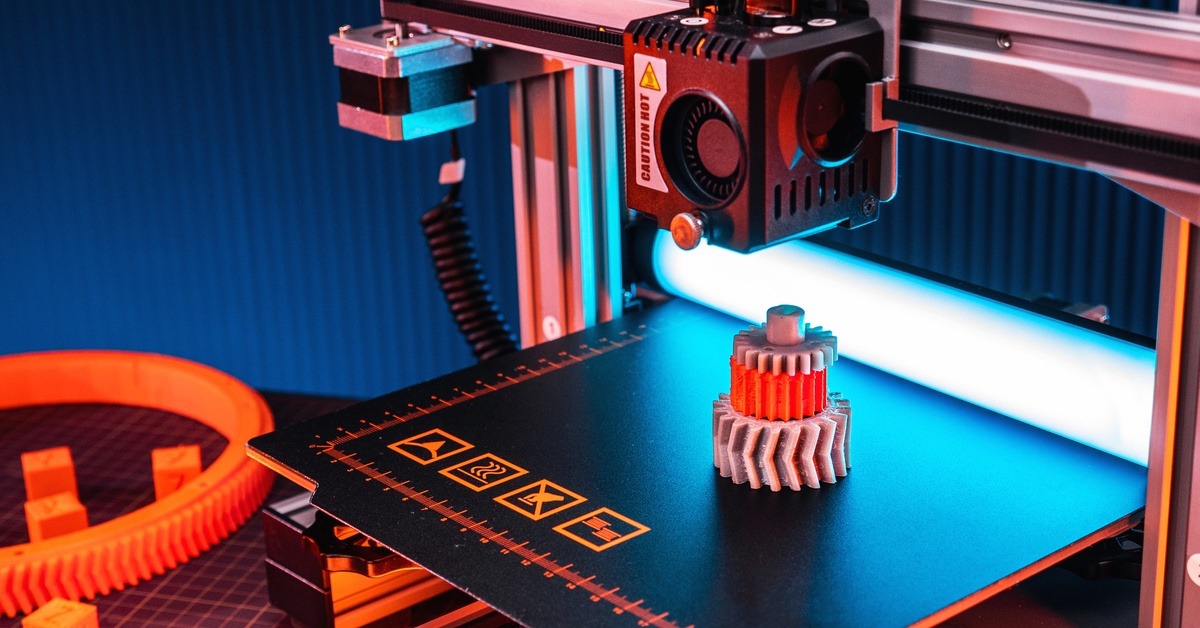

While 3D printing often grabs the headlines for its ability to seemingly create objects out of thin air, it doesn’t exist in a vacuum. For many engineers, designers, and manufacturers, the true power of additive manufacturing is unlocked when pairing it with 3D scanning.

Individually, these technologies are impressive. 3D scanning captures the physical world in high-definition digital detail, while 3D printing turns digital files into physical reality. But when combined, 3D scanning and 3D printing work together to create a seamless workflow that bridges the gap between the physical and digital realms. This synergy streamlines processes, solves complex engineering challenges, and opens the door to innovations that were previously impossible.

Bridging the Gap Between Physical and Digital

The core relationship between 3D scanning and 3D printing is cyclical. It represents a “physical-to-digital-to-physical” workflow. It starts with 3D scanning. Using structured light, lasers, or photogrammetry, a scanner captures the precise geometry and texture of a real-world object. This process generates a point cloud—millions of data points that map the object’s surface. Software then converts this point cloud into a polygon mesh, which serves as a highly accurate 3D digital model.

Once the object exists in the digital space, it becomes the foundation for 3D printing. You aren’t starting from a blank screen; you are starting with a precise digital twin of a physical object. Teams can then export this digital model as an STL or OBJ file, slice it, and then send it to a 3D printer. This capability allows you to take an object from the real world, digitize it, and reproduce it with incredible fidelity, effectively closing the loop between the two technologies.

Enhancing Design and Iteration

In traditional product development, designing a new part often requires manual measurements with calipers and micrometers—a slow, error-prone process. 3D scanning accelerates the design phase by providing an accurate starting point immediately.

For example, if you are designing an aftermarket accessory for a car, you don’t need to model the car’s body panels from scratch. You can simply scan the vehicle to obtain the exact dimensions and mounting points. You can also import this scan data directly into CAD software, allowing you to design your new part around the existing geometry with perfect precision.

This workflow also supercharges iteration. The process typically looks like this:

- Scan the prototype or the environment it needs to fit into.

- Modify the design in your CAD software based on the scan data.

- Print the updated prototype.

- Rescan the printed part to verify dimensional accuracy against the original design.

By integrating scanning into the prototyping phase, you reduce the trial-and-error often associated with complex geometries, significantly shortening the product development lifecycle.

Reverse Engineering and Replication

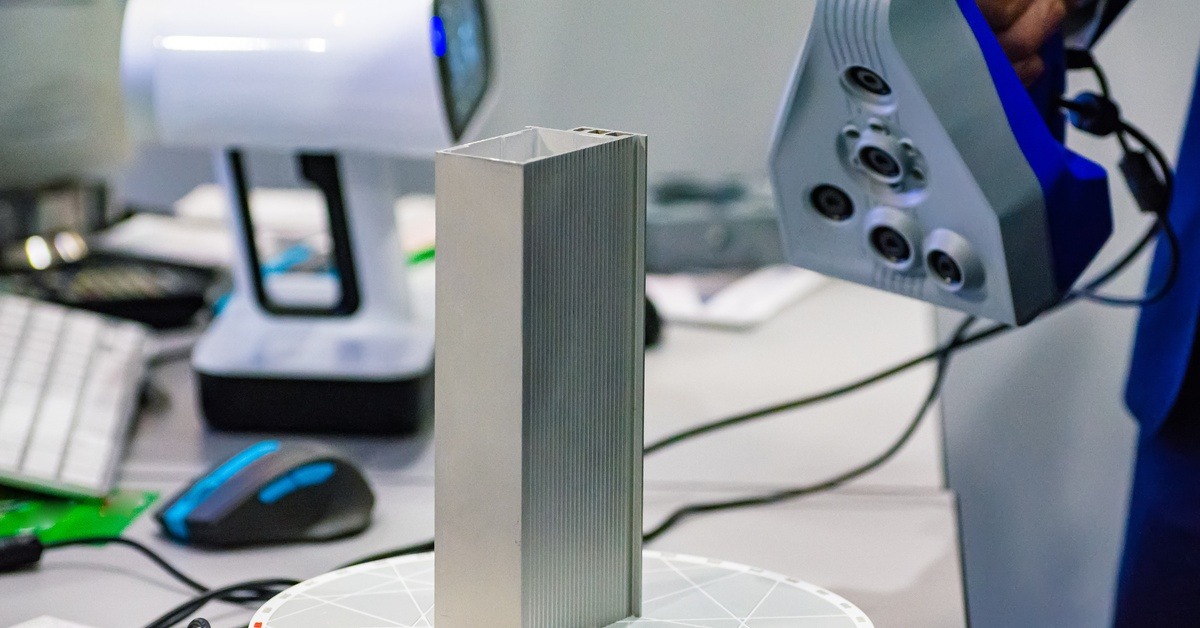

One of the most valuable applications of this technological pairing is reverse engineering. In industries like manufacturing and automotive restoration, you often encounter legacy parts that are broken or worn out, for which no original CAD files or blueprints exist.

3D scanning technology has revolutionized the reverse engineering process, making it faster, more accurate, and more efficient than ever before. Instead of manually measuring complex curves and internal cavities, a 3D scan captures the entire geometry in minutes.

Once scanned, specialized software allows engineers to reconstruct the object’s parametric design data. This isn’t just about making a copy; it’s about restoration and improvement. You can fix the wear and tear digitally, reinforcing weak points or optimizing the topology for better performance. Once the digital model is restored, a 3D printer can produce a functional replacement part on demand.

Customization at Scale

In many cases, traditional manufacturing methods are often limited by the high costs associated with custom molds and tooling, making customization impractical at scale. In contrast, integrating 3D scanning with 3D printing unlocks true mass customization—producing tailored products efficiently, without the expense of retooling for each unique item.

With this workflow, precise 3D scans capture individual specifications or design variations, instantly converting them into digital models. Teams can then adjust or optimize these models digitally using software, allowing them to more easily incorporate unique features, fit, or aesthetics on a case-by-case basis. 3D printing then seamlessly turns these variations into physical products, maintaining efficiency and quality across small batches or even single-unit runs.

The result is a manufacturing process where customization is the standard, not the exception—delivering products that meet specific needs or preferences while maintaining production speed and cost-efficiency.

Real-World Synergy: Applications Across Industries

As you can expect, the collaboration between 3D scanning and 3D printing is reshaping workflows across a diverse range of sectors. While it’s best to hire professionals to perform these tasks, knowing how they could apply to processes in your field will give you a better idea of what to look for when searching for 3D CAD drawing services.

Healthcare

Surgeons are using 3D scanning to capture patient anatomy (often via CT or MRI data converted into 3D models) to plan complex procedures. It’s then possible to use this data to 3D print clear, biocompatible surgical guides that fit perfectly onto a patient’s bone structure, guiding drills and incisions with sub-millimeter precision.

Manufacturing

On the factory floor, efficiency is everything. Manufacturers use 3D scanning to inspect tools and fixtures for wear. If a jig is damaged, it can be scanned, reverse-engineered, and 3D printed overnight, preventing costly downtime. Furthermore, companies are moving toward “digital inventory,” where spare parts are stored as digital files rather than physical stock, ready for printing only when needed.

Art and Heritage

Many museums and preservationists use 3D scanning to digitally archive fragile artifacts. If a piece is damaged, they can use the scan data to 3D print a replica for display, allowing the public to interact with history while the original remains safely stored. It also aids in restoration, where teams can model missing fragments of a piece and print them to complete the artwork.

Aerospace and Automotive

In high-performance industries, every gram of weight matters. Professionals scan engine bays or fuselages to fully understand the spatial constraints. They then use 3D printing to manufacture optimized, lightweight components that fit into those tight spaces, often consolidating multiple parts into a single printed unit to improve aerodynamic performance and fuel efficiency.