Client: Bayliss Machine & Welding

Location: Birmingham, Alabama

Services: Mobile 3D Scanning, Reverse Engineering, 2D Print Creation

Overview

Tangent Solutions specializes in large-format 3D scanning, reverse engineering of legacy parts, and on-demand CAD support. Our team travels across the U.S. offering fully mobile 3D scanning services —making it easy to support clients in the field, shop, or plant floor.

Our newest mobile 3D scanning project is from Bayliss Machine & Welding. Bayliss, based in Birmingham, Alabama, is a long-standing industrial service provider known for its ability to repair and restore heavy equipment dating back to the early 1900s.

With deep expertise in servicing antique and legacy machinery, Bayliss fills a critical role in American industry by preserving the function of machines that would otherwise be retired due to a lack of documentation or support.

When Bayliss needed to replace a cracked Babbitt bearing half from a vintage industrial grinder, they turned to Tangent Solutions to help reverse engineer the part. Without any original CAD files or drawings, the only viable solution was to scan the part directly on-site and rebuild it digitally from scratch.

The Challenge: No Drawings, No CAD, No Spare Parts

Bayliss encountered a common but urgent problem: a large Babbitt bearing half from an early 20th-century industrial grinder had cracked, and a replacement was needed fast. Unfortunately, there were no technical drawings, CAD models, or part numbers available—just the damaged part itself.

This type of bearing, over 54 inches in ID, was too large to transport and too custom to replace without detailed dimensional data. The only path forward was to reverse engineer the bearing based on its current geometry.

This situation is emblematic of what many shops and plants across the U.S. are facing—aging machines still in service, but no way to maintain or rebuild them using traditional sourcing channels. In these cases, engineering-grade 3D scanning becomes a mission-critical solution.

What is a Babbitt Bearing?

Babbitt bearings, made from soft white metal alloys, are commonly used in rotating equipment because of their ability to conform to shaft imperfections and run without galling. These bearings are still found in legacy machinery, including turbines, compressors, and grinders—especially in systems dating back to the early-to-mid 1900s.

Their large scale and one-off design make them hard to replace. Typically poured and machined in place, these parts often lack symmetry and include hand-fitted tolerances that are difficult to replicate manually. Without accurate reverse engineering, modernizing or repairing these parts would be guesswork.

Why Bayliss Chose Tangent Solutions

Bayliss needed a partner who could:

- Accurately scan a legacy part over four feet in diameter

- Perform scanning on-site, avoiding costly or risky transport

- Deliver high-resolution CAD data for immediate manufacturing

- Work quickly and efficiently to minimize downtime

Tangent’s mobile large format 3D scanning solution checked every box.

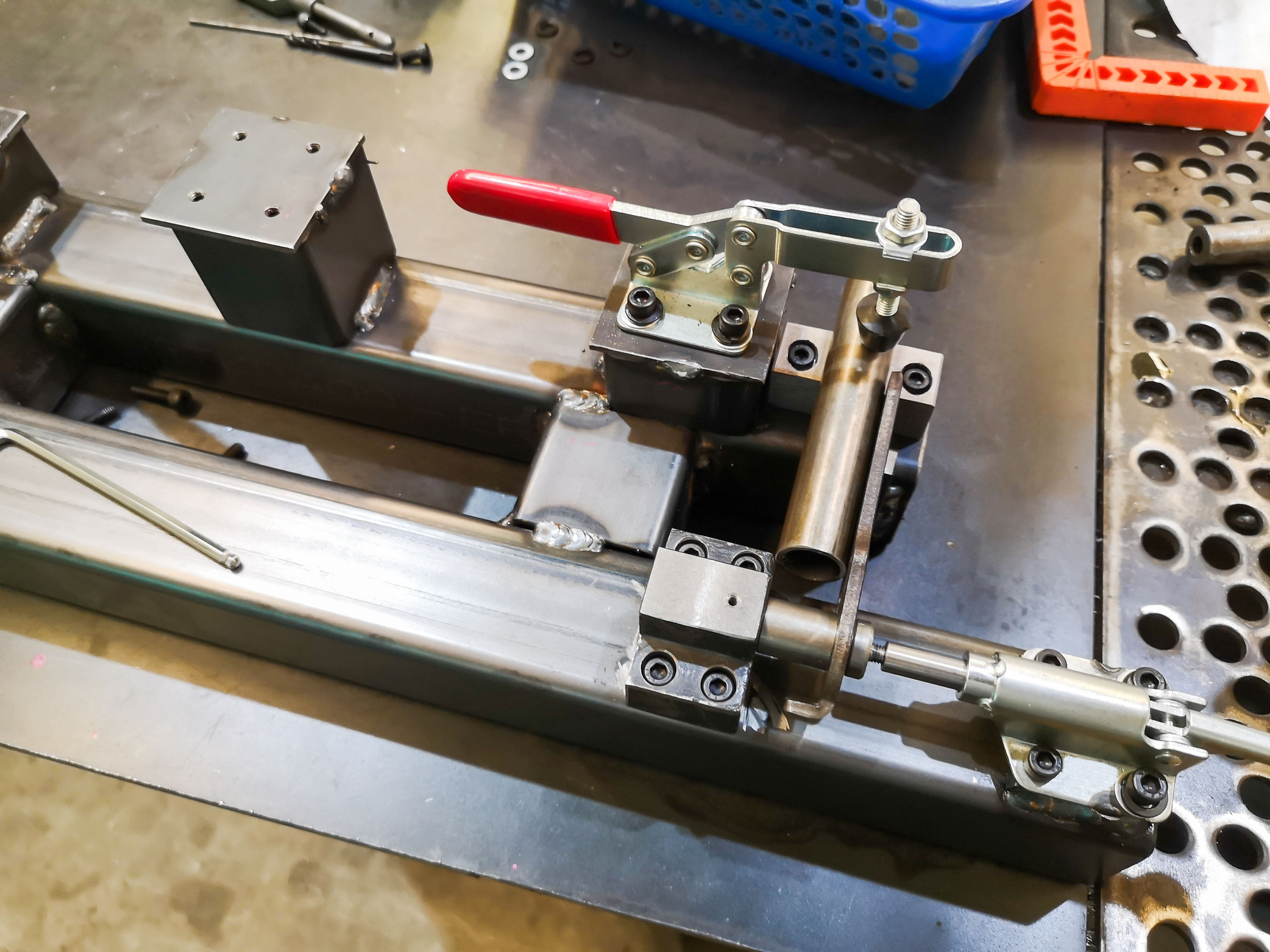

Using the Creaform HandySCAN BLACK Elite, a metrology-grade portable laser scanner, we were able to perform the entire scan on the shop floor in Birmingham. Our setup required no special rigging, jigs, or dark rooms—just a single 110V outlet and the part itself.

Our Scanning Process

Once on site, our team began preparing the bearing for scanning. Although it was cracked, the overall geometry was intact enough to provide a usable reference for reconstruction.

The Creaform HandySCAN BLACK Elite allowed us to:

- Capture high-resolution scan data with an accuracy of up to 0.025 mm (0.0009 in)

- Scan without the need for spray or markers in most cases

- Complete the entire scan in just a few hours

Because the part was symmetrical, we scanned one half in full detail and used that geometry to mirror and rebuild the complete component during reverse engineering. This method also helped correct for deformation and damage caused by the crack.

Reverse Engineering & CAD Modeling

Once back at our facility, Tangent’s reverse engineering team imported the raw scan mesh into our digital workflow; rebuilding the bearing geometry from the scan data.

Key steps included:

- Mesh cleanup to remove noise and non-manifold geometry

- Cross-section analysis to identify critical features and wall thicknesses

- Parametric modeling of the bearing housing and key geometries

- Creation of a full 2D print, suitable for downstream CNC machining and quality control

The final deliverables to Bayliss included:

- A fully parametric STEP file

- Native SolidWorks CAD files

- A dimensioned 2D engineering drawing with material and tolerance notes

With this data in hand, Bayliss was able to confidently move forward with producing a new bearing—accurate, repeatable, and fully documented for future service.

The Advantages of Mobile 3D Scanning for Legacy Equipment

This project is a perfect example of how modern scanning technology can breathe new life into legacy systems.

Benefits to Bayliss included:

- No need to move or ship the 54″ part

- Quick, non-contact data collection on-site

- Digitally preserved part geometry for future use

- Accurate reproduction with reduced lead time and risk

For companies working with antique or undocumented equipment, reverse engineering with mobile 3D scanning is often faster, safer, and more cost-effective than trying to fabricate a part manually or hunt down an obsolete replacement.

Why Work With Tangent

At Tangent Solutions, we make engineering on demand scalable and accessible. Whether you need a single scan or a full end-to-end design package, we tailor our services to your needs.

For Bayliss, this meant:

- Affordable travel to Birmingham

- On-site scan and same-day data capture

- Reverse engineering support from scan to 2D print

- Coordination with their in-house machining workflow

We offer custom service packages for repair shops, OEMs, foundries, aerospace, defense, and heavy industry—anywhere large-scale or legacy equipment is in use.

Conclusion: Bridging the Gap Between the Past and the Future

Legacy parts like Babbitt bearings are a challenge to maintain—but not impossible. With modern tools like metrology-grade 3D scanning and CAD reconstruction, even one-of-a-kind, undocumented components can be restored and returned to service quickly and accurately.

Tangent Solutions is proud to help companies like Bayliss Machine & Welding keep America’s industrial backbone running—one scan at a time.

Need Help With a Legacy Part?

Whether you’re dealing with an obsolete motor housing, a custom casting, or a cracked bearing, Tangent Solutions can help. Our team specializes in:

Mobile 3D Scanning Services

Large Format 3D Scanning

Reverse Engineering of Legacy Parts

2D Print and CAD File Creation

Contact us today to learn more about our tailored packages, including affordable travel rates, quick turnarounds, and complete CAD support.

Schedule a Call

Learn About Reverse Engineering Legacy Parts