If you work in the oil and gas industry, you know that its extreme environmental conditions can make general work and safety more difficult. Because of that, standard measurement and documentation methods of industrial equipment aren’t always productive or possible.

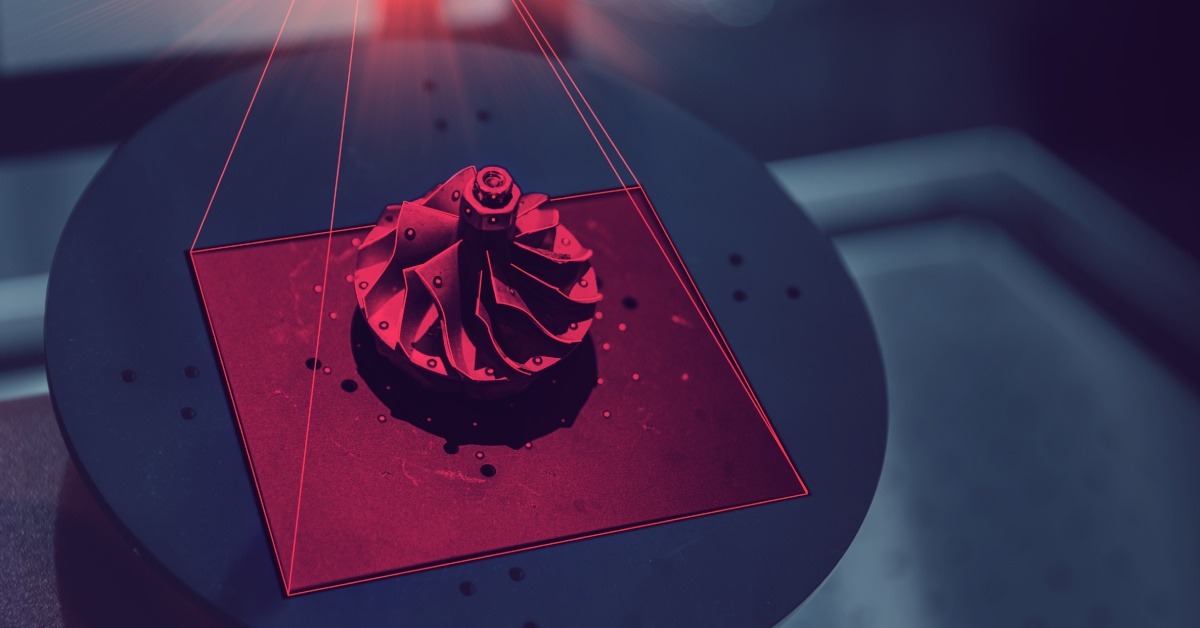

Laser scanning technology is an effective approach because oil and gas companies can capture comprehensive, highly accurate 3D data of their facilities, pipelines, and equipment without putting personnel at risk. Nevertheless, it can do even more! That’s why we’re here to cover the benefits that oil and gas industry companies can expect when leveraging laser scanning technology.

Laser Scanning Technology

If you’re unfamiliar with laser scanning, let’s quickly go over the important features you should know about it. The process itself is quite simple. The device will shoot off millions of laser pulses every second, tracking how long it takes each pulse to return to map out the target’s surface. Knowing this info allows the scanner to create a digital imprint of the object on your computer.

The process, LiDAR (light detection and ranging), creates highly detailed point clouds that represent the exact geometry of scanned objects and environments. Each point in the cloud contains precise X, Y, and Z coordinates, creating a comprehensive digital twin of the physical space.

The device captures the data quickly and accurately to process the information correctly. Advanced laser scanners can collect hundreds of thousands of points per second. Many units achieve measurements within one to three millimeters of actual dimensions.

Types of Laser Scanners Used in Oil and Gas

The oil and gas industry utilizes several types of laser scanning systems, each designed for specific applications and environments. Here’s a deeper look at each of them:

- Terrestrial laser scanners are tripod-mounted systems designed for detailed facility documentation and piping surveys. These scanners excel in refineries, processing plants, and onshore facilities that require comprehensive interior and exterior documentation.

- Portable laser scanning systems are mountable devices that capture linear assets, like pipelines and access roads, or small objects that need digitizing. Users can mount them to vehicles or use them by hand. They’re particularly valuable for measuring minuscule details of precise objects.

- Aerial laser scanning features drones or aircraft-mounted scanners to capture large-scale topographical data and access hard-to-reach areas, such as offshore platforms or elevated structures. This approach proves invaluable for environmental assessments and overall site planning.

Key Benefits of Laser Scanning

Laser scanning technology offers a multitude of advantages across the oil and gas industries because it enables precise data collection and improved project efficiency. Here’s a look at the key benefits of utilizing these devices.

Enhanced Measurement Accuracy

Where manual measurements could vary by several inches, laser scanning consistently provides millimeter-level precision across entire facilities. The accuracy becomes critical when planning modifications to existing infrastructure or ensuring proper fit-up of new equipment.

The technology also eliminates human error associated with manual measurements. It becomes possible to audit and verify data. When designing tie-ins to existing pipelines or planning equipment installations, this level of precision prevents costly field conflicts and facilitates first-time fit success.

Improved Workplace Safety

Safety remains the top priority in oil and gas operations, and laser scanning significantly reduces personnel exposure to potentially hazardous environments. Instead of sending teams into dangerous areas with a measuring tape, a theodolite, and surveying chains, operators can capture comprehensive data remotely using laser scanning technology.

Leveraging this advanced technology is especially valuable in active production areas, confined spaces, or elevated structures because it decreases the need for extensive safety protocols and risk mitigation measures. Workers can obtain comprehensive documentation without shutdowns, production interruptions, or putting their safety at risk.

Time and Cost Efficiency

Laser scanning dramatically reduces the time required for facility documentation and survey activities. Projects that previously needed weeks can now take place within days. A single scanner operator can capture data equivalent to what might require a team of surveyors using traditional methods.

This also applies to small-scale tasks. For example, measuring a pipe by hand takes time and sometimes requires the assistance of multiple people. Scanning the pipe with a portable scanner takes only one person, and the task can come to an end in mere seconds.

The efficiency gains in either scenario extend beyond initial data capture. Because laser scanning provides complete documentation rather than selective measurements, future projects can leverage existing scan data, reducing the need for return site visits and additional manual work.

Refined Data Management and Collaboration

All of this means that laser scan data will create a permanent digital record that you can share across project teams, store for future reference, and integrate with software platforms. This kind of digital documentation ensures that accurate as-built information remains available throughout the facility’s lifecycle.

The 3D nature of scan data also helps stakeholders visualize projects more effectively than traditional 2D drawings. Design teams can work collaboratively within the same digital environment, reducing miscommunication and ensuring all parties work from consistent, accurate information.

Applications of Laser Scanning in the Oil and Gas Sector

Now that you know its benefits, let’s take a look at how you might be able to implement this kind of technology. That way, you can ensure you get the most you can out of its usage.

Reverse Engineering

When original drawings are unavailable or inaccurate, laser scanning enables complete reverse engineering of existing facilities and equipment. This application proves particularly valuable for aging infrastructure, but businesses have a variety of uses for it.

With the scanned data, workers will be able to provide the foundation for creating accurate 3D models and technical drawings that reflect current conditions. These models serve as the basis for maintenance planning, modification design, and regulatory compliance documentation.

Asset Management and Maintenance

Laser scanning supports comprehensive asset management as well by creating detailed digital inventories of equipment and infrastructure. Maintenance teams can use scan data to plan work activities, order correctly sized replacement parts, and optimize maintenance procedures.

The technology also enables condition monitoring by comparing scans taken at different time intervals. This capability helps identify structural changes, corrosion patterns, or equipment wear that might indicate maintenance needs or safety concerns.

Construction and Facility Modifications

During construction and modification projects, laser scanning ensures new installations integrate properly with existing infrastructure. Preconstruction scanning identifies potential conflicts early in the design phase. Progress scanning validates construction quality and dimensional compliance.

The technology supports modular construction approaches by enabling precise prefabrication of components that will fit perfectly when installed. As a result, oil and gas companies can reduce field construction time and improve the efficiency of the project execution.

How We Can Provide Assistance

If you’re ready to take advantage of laser scanning, Tangent Solutions can help. We provide 3D laser scanning services for small-scale items. With the use of our portable scanning devices, we can accurately map parts that need replacing and various objects you would like to digitize for the company. Our team will be sure to obtain extremely accurate readouts so you can continue operations without delays.