3D laser scanning technology is a powerful tool that captures the precise shape and size of physical objects, creating highly accurate digital models. While it has made significant waves in industries like manufacturing and engineering, its relevance in the fashion world is rapidly growing. This technology is proving to be a game-changer, offering innovative solutions that are transforming how garments are designed, produced, and sold. Let’s explore why 3D laser scanning is becoming so crucial for the fashion industry.

Enhancing Design Precision

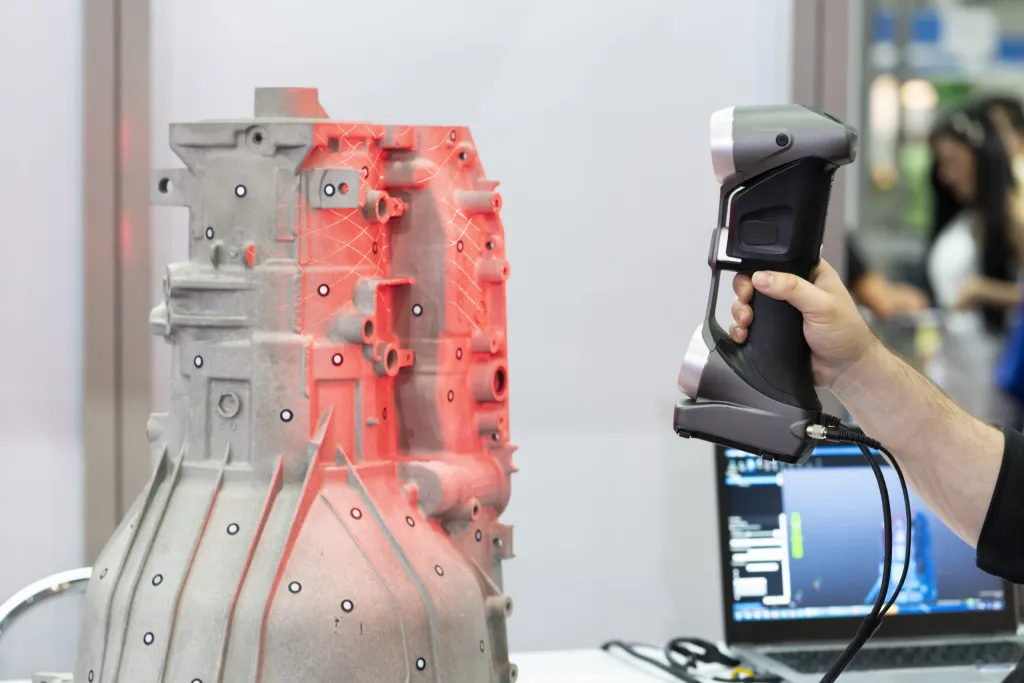

Given how quickly fashion trends shift, design accuracy and efficiency are crucial for staying ahead. 3D laser scanning technology brings unprecedented precision to the initial stages of the design process, streamlining everything from concept development to prototyping. By scanning mannequins, live models, or even existing garments, designers can create detailed digital models that serve as reliable templates throughout the design journey. This is especially helpful when you need reverse-engineering solutions that can bring older styles back to life.

Regardless of the reason, this kind of digital data enables brands to experiment with virtual samples and make iterative design changes quickly, reducing their reliance on physical prototypes. The result? Shorter development cycles, fewer material costs, and a drastic reduction in errors during pattern creation and garment assembly.

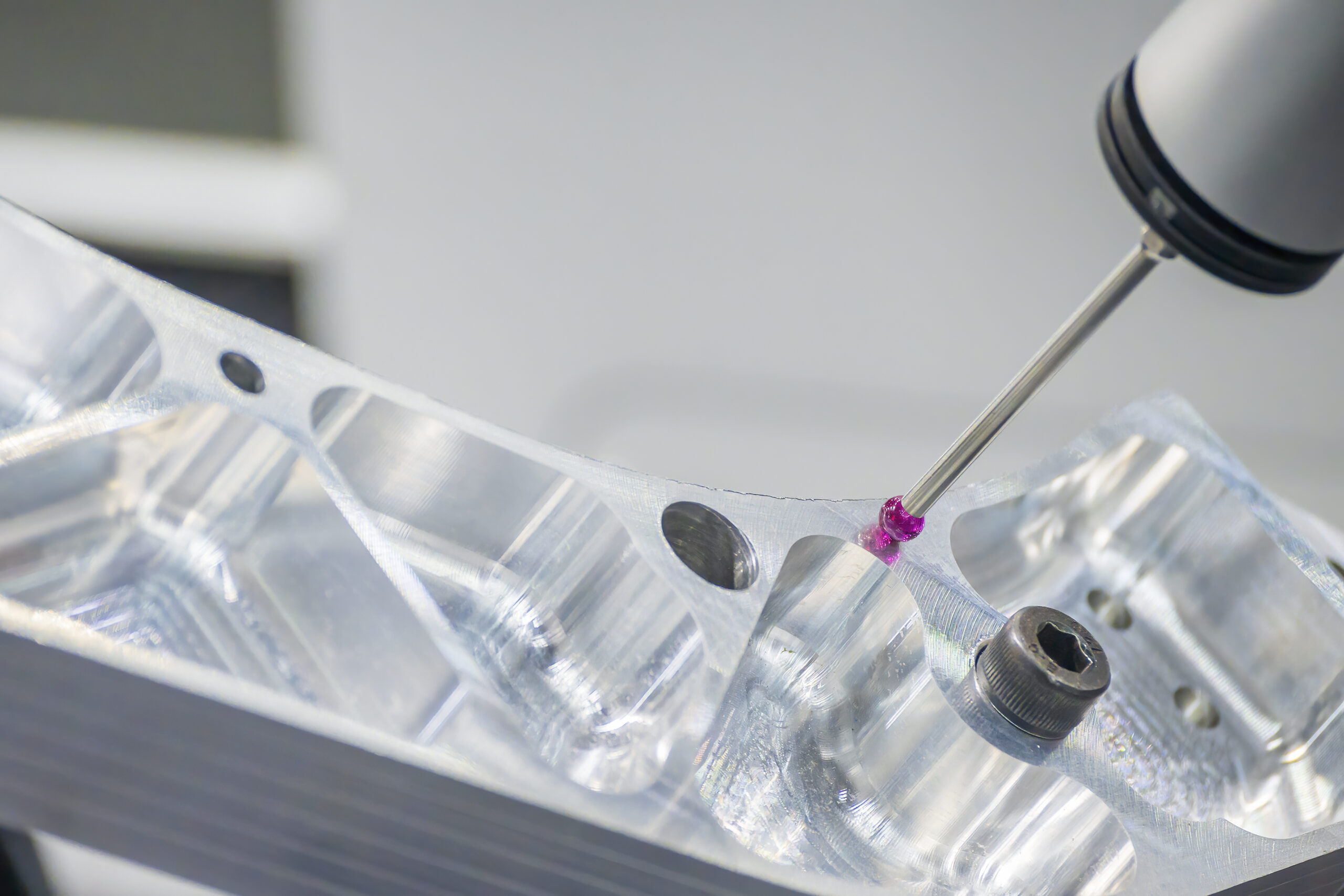

On a broader scale, 3D scanning supports the development of standardized sizing systems based on real-world data, addressing inefficiencies caused by outdated manual measurement techniques and generic sizing charts. Ultimately, this technology elevates the quality and consistency of fashion collections while streamlining production workflows.

Furthermore, 3D scanning can help the industry become more inclusive. Standard sizing charts have long been a source of frustration for many shoppers who don’t fit into conventional size categories. 3D scanning allows brands to gather extensive data on a wide range of body types, leading to the development of more inclusive sizing systems that cater to a broader audience.

This technology also powers virtual try-on experiences, where shoppers can see how a garment will look on a digital avatar of themselves. This personalized shopping experience not only increases customer confidence but also helps reduce the high return rate associated with online shopping.

Revolutionizing Customization and Fit

While precise digital models improve efficiency and standardization, 3D laser scanning also empowers brands to push the boundaries of personalization. With the ability to capture millions of data points from an individual’s body in seconds, 3D scanners create highly accurate digital twins. This level of detail forms the foundation for authentic made-to-measure apparel and mass customization initiatives.

This is perfect for many of today’s consumers who are looking for products made just for them. The rise of mass customization is a direct response to this demand, and 3D laser scanning is a key enabler of this trend. By capturing precise body measurements, fashion brands can offer made-to-measure clothing on a much larger scale, giving customers a personalized fit without the high price tag of traditional bespoke tailoring.

Streamlining Prototyping and Sampling

The journey from a design sketch to a finished garment traditionally involves numerous physical prototypes and samples. This process can be slow, expensive, and wasteful. 3D scanning technology offers a more efficient and sustainable alternative by streamlining the prototyping and sampling stages.

How does it work? Instead of creating multiple physical samples, designers can use 3D scans to generate virtual prototypes. They can then use these digital models to drape, fit, and adjust clothing on a virtual avatar, allowing designers to visualize how a garment will look and move without ever cutting a piece of fabric. This digital-first approach provides several key benefits:

- Time Savings: Virtual prototyping is significantly faster than creating physical samples, allowing designers to iterate on their ideas more quickly and bring products to market sooner.

- Cost Reduction: By minimizing the need for physical materials and shipping, 3D scanning helps reduce the overall cost of product development.

- Sustainability: Reducing the number of physical samples created also means less material waste, contributing to more sustainable and environmentally friendly practices within the fashion industry.

Supporting Digital Fashion and Virtual Runways

As the digital world continues to expand, so too does the world of digital fashion. Both virtual reality (VR) and augmented reality (AR) are creating new platforms for creative expression, and 3D scanning is playing a crucial role in this evolution.

3D scanners can help here as well by creating realistic digital garments that can be worn by avatars in virtual environments or overlaid onto the real world through AR. This technology is essential for creating lifelike textures, drapes, and movements that make digital clothing believable.

From virtual fashion shows that reach a global audience to interactive AR filters on social media, 3D scanning is helping to bridge the gap between the physical and digital fashion worlds. As digital fashion becomes more mainstream, the importance of 3D scanning in creating these immersive experiences will only continue to grow.

Improving Supply Chain Efficiency

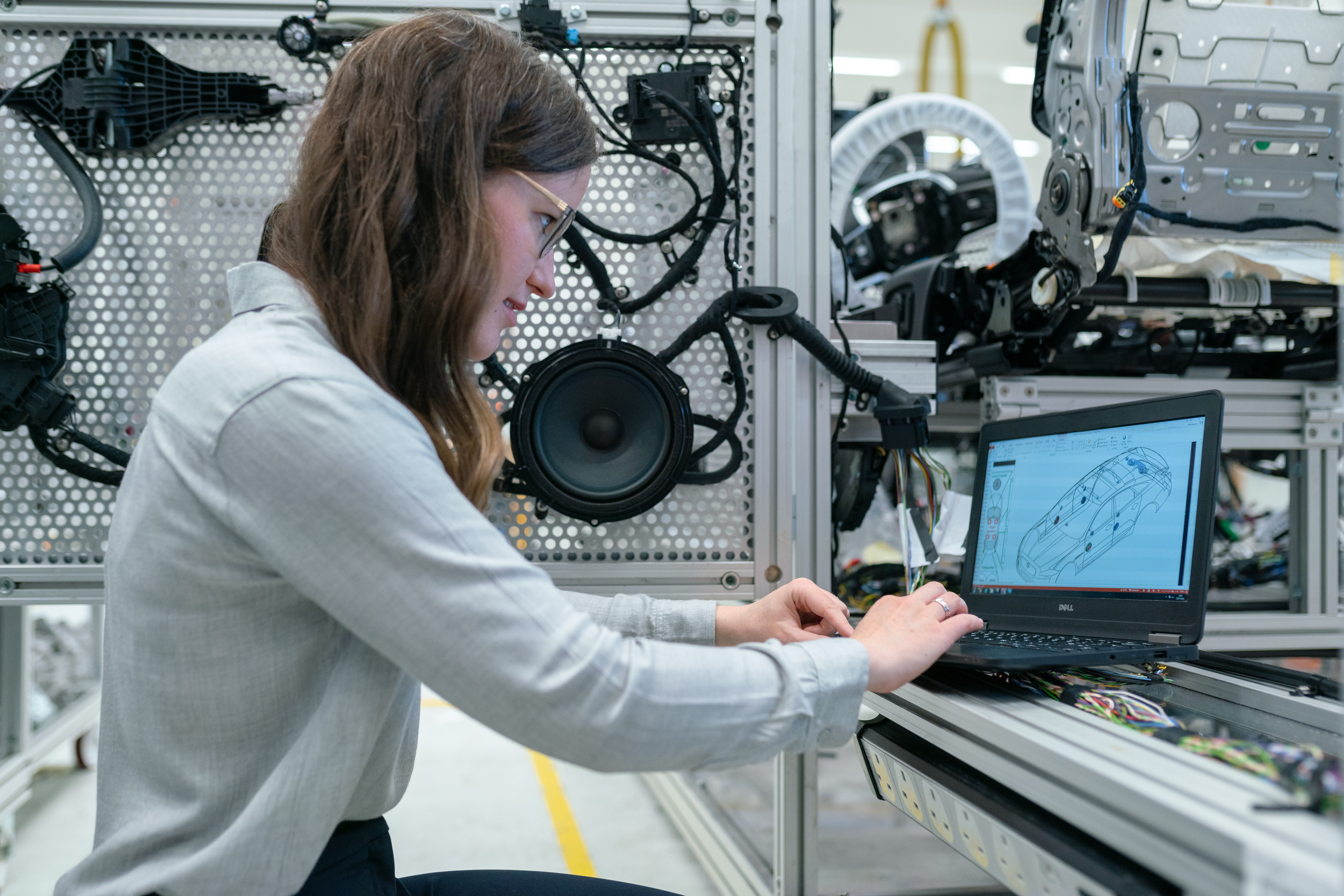

The reasons for 3D laser scanning being important in the fashion industry even extend beyond the design studio and into the entire supply chain. By creating accurate digital models of products, this technology helps optimize production processes and improve overall efficiency. For example, teams can send precise digital patterns directly to automated cutting machines, reducing material waste and ensuring consistency across all manufactured items.

3D scanning also helps with inventory management. With a digital catalog of products, retailers can better track stock levels and forecast demand. This data-driven approach helps prevent overproduction and reduces the need for excess inventory, leading to significant cost savings.

Moreover, the digital assets created through 3D scanning enhance collaboration between designers, manufacturers, and retailers. Everyone involved in the process can access the same accurate information, leading to better communication and a more streamlined workflow from concept to consumer.

Preserving Historical Fashion

Something that can be easy to forget in this industry is that fashion is not just about the future; it’s also about preserving the past. Historical garments are often fragile and delicate, making them difficult to study or display. 3D laser scanning provides a non-invasive way to digitize these precious artifacts, creating detailed 3D models that you can preserve for future generations.

These digital replicas serve multiple purposes. Museums and archives can use them to create virtual exhibitions, allowing people from all over the world to explore fashion history without risking damage to the original items. Researchers and students can study the construction and design of historical garments in intricate detail, gaining valuable insights into the techniques of the past. In some cases, these digital models can even be used to create physical replicas for exhibitions or educational purposes, ensuring that the legacy of fashion history continues to inspire and inform.