NASCAR is a sport where milliseconds matter and every detail counts. From aerodynamics to safety features, teams constantly search for ways to gain an advantage over their competitors. Technology has become essential in this pursuit, and one tool has emerged as a game-changer: 3D scanning.

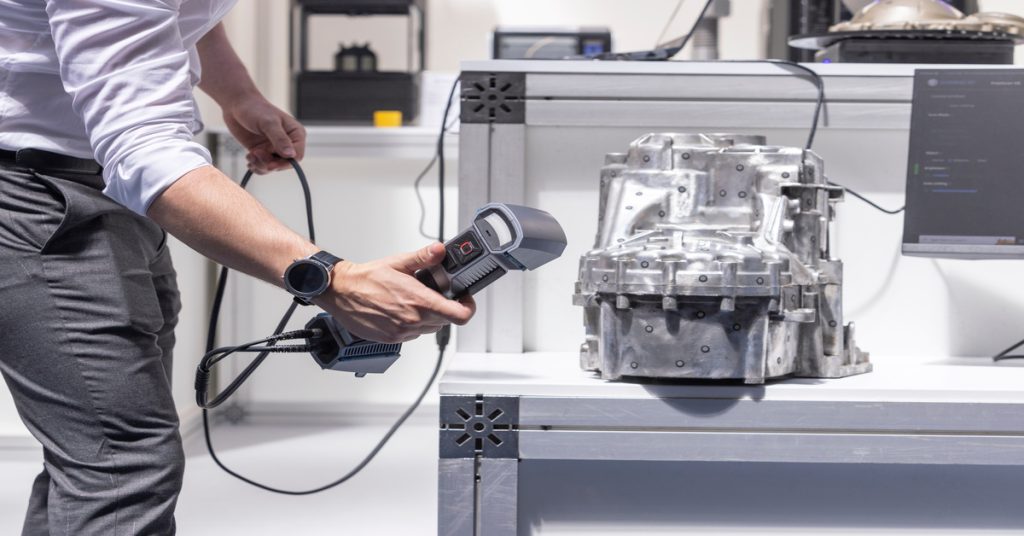

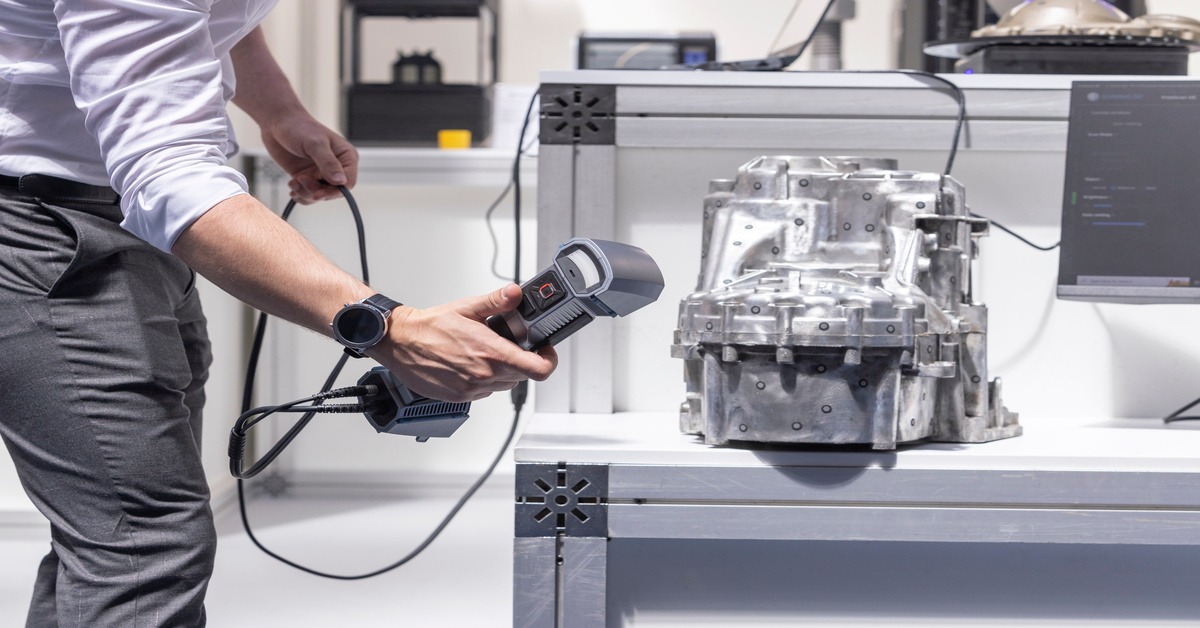

3D scanning uses laser or optical sensors to capture the precise dimensions and geometry of physical objects, creating detailed digital models. In NASCAR, this technology allows teams to analyze cars with incredible accuracy, optimize designs, and make data-driven decisions that can mean the difference between victory and defeat. Here’s a more detailed look at how 3D scanning is benefiting NASCAR racing.

Enhancing Vehicle Design and Aerodynamics

Aerodynamics plays a crucial role in NASCAR performance. A car that cuts through the air efficiently gains speed, stability, and fuel economy. Engineers rely on 3D scanning to capture exact measurements of car bodies, test different configurations, and refine designs before any metal is cut or welded.

By scanning existing vehicles, teams can create digital models that simulate airflow patterns. These simulations reveal how air flows around the car, where drag occurs, and what can be done to address downforce issues. Engineers can then make adjustments digitally, testing multiple variations without the cost and time of building physical prototypes.

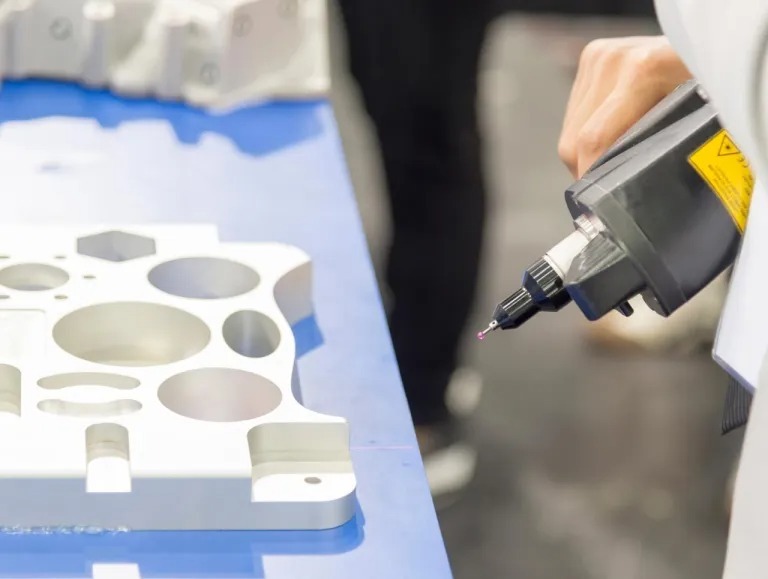

Something important to recognize here, though, is that NASCAR has strict rules governing car dimensions and specifications. A vehicle that doesn’t meet these standards faces disqualification, no matter how fast it is. 3D scanning can still help here by ensuring compliance through the use of precise measurements that teams can verify against NASCAR’s technical guidelines. Each team can scan their cars at various stages of development to confirm they’re within regulation, avoiding costly mistakes and penalties.

To put all of this into context, a team might use 3D scanning to optimize the shape of the front splitter or rear spoiler. Then use that same tech to ensure their new designs comply with regulations. With the right changes, these minor tweaks might only reduce drag by fractions of a percent, but at speeds exceeding 200 mph, those fractions translate into tangible gains on the track.

Improving Maintenance and Repairs

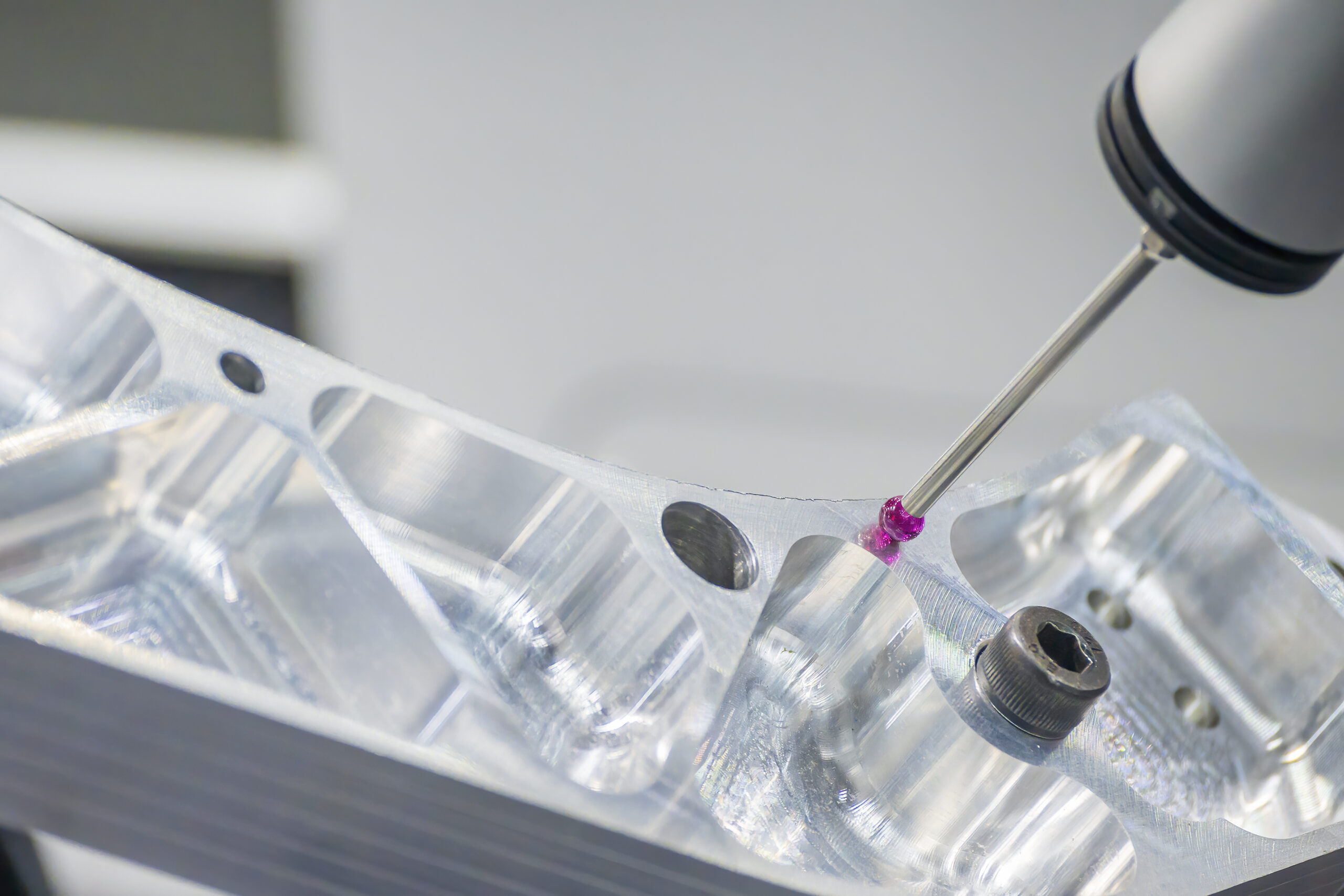

It’s no secret that NASCAR vehicles endure extreme conditions. High speeds, tight turns, and occasional contact with other vehicles take their toll on components. Identifying wear and tear quickly is essential, and 3D scanning makes this process faster and more accurate.

By scanning parts before and after races, teams can detect deformations, cracks, or other damage that might not be visible to the naked eye. This allows mechanics to address issues before they lead to failures on the track. Instead of guessing whether a part needs replacement, teams have concrete data to guide their decisions.

When repairs are necessary, 3D scanning provides a blueprint for creating replacement parts. Traditional methods might involve manual measurements or trial-and-error, but scans deliver exact specifications. This precision ensures that new components fit perfectly and perform as intended.

Also, time is a critical factor during race weekends. Teams often have limited hours between practice sessions, qualifying rounds, and the main event. 3D scanning speeds up diagnostics and repair planning, allowing crews to work efficiently under pressure. A quick scan can reveal exactly what needs fixing, enabling mechanics to focus their efforts where they’re needed most.

Data-Driven Performance Analysis

Success in NASCAR requires more than a fast car. Teams need to understand how their vehicles perform under different conditions and how they stack up against the competition. 3D scanning benefits NASCAR here as well, thanks to the wealth of data it provides, fueling better performance analysis and strategic planning.

After each race or practice session, teams can scan their cars to document the exact condition of every component. By comparing these scans over time, engineers identify patterns and trends. They might discover that certain parts wear faster on particular tracks or that specific setups deliver better results in certain weather conditions.

This data also enables teams to benchmark their cars against competitors. While NASCAR’s rules create a relatively level playing field, subtle differences in design and setup can have significant impacts. By analyzing scans of rival vehicles (when possible), teams gain insights into what works and what doesn’t, informing their own development efforts.

3D scanning also plays a role in simulation and testing. Engineers can use scanned models to run virtual race scenarios, testing different strategies without risking real equipment. These simulations help teams predict how changes will affect performance, allowing them to make informed decisions about which modifications to implement.

Enhancing Driver Safety

While winning is the main goal here, it should never come at the detriment of driver safety. Fortunately, NASCAR has made tremendous strides in protecting drivers. Still, there’s always room for improvement, and 3D scanning contributes to this effort by helping teams design safer cars and equipment.

One application is in crash analysis. When accidents occur, teams can scan damaged vehicles to understand exactly what happened. These scans reveal how forces impacted the car, which components absorbed energy, and where structural failures occurred. This information guides improvements to future designs, making cars more resistant to impacts.

Roll cages, the internal framework that protects drivers during crashes, must be precisely engineered to meet safety standards while fitting within the car’s body. 3D scanning ensures that roll cages are built to exact specifications and properly integrated with other safety features.

Seats are another critical safety component. A well-designed seat keeps the driver secure during high-G maneuvers and cushions impacts during crashes. 3D scanning allows teams to create custom-fitted seats tailored to each driver’s body shape and size. This customization improves comfort during long races and enhances protection by ensuring the seat provides optimal support in all the right places.

Helmets also benefit from 3D scanning technology. By scanning a driver’s head, manufacturers can create helmets that fit perfectly, reducing the risk of movement during impacts. Better-fitting helmets are more comfortable and provide superior protection, giving drivers confidence as they push their cars to the limit.

How To Start Utilizing 3D Scanning

If you’re sold on the idea of using 3D scanning technology to improve your NASCAR results, Tangent Solutions is here to help. We provide top-tier 3D CAD modeling services and have the knowledge needed to help make sense of the data you get from scanning your vehicle. Simply reach out to us to learn more about how we can fully assist you.