The aerospace industry relies heavily on the accuracy and precision of thousands of parts that go into designing an airplane. Validating the integrity of each part confirms whether an airplane has thousands of flying hours or an aviation disaster. How can 3D laser scanning be used in the aerospace industry?

Whether it be tiny moving parts or whole engine designs, 3D scanning for aerospace allows for the simplification of design and quality assurance of aircraft components. 3D laser scanning is used by aerospace companies for reverse engineering, measurement, andinspection.

Due to the high precision required in the aerospace sector, 3D scanning for aerospace is a perfect technology to be used. Scan data is used to highlight damage, unseen by the human eye or even create legacy parts for aircraft since retired. 3D laser scanning holds the key to delivering outputs that are ultra accurate, ultra precise, and ultra resolution.

3D Scanning for Aerospace – Pros and Cons

Businesses within the aerospace industry may be considering using 3D laser scanning for a number of reasons. Is it best to use a service provider or invest in the equipment? To summarize, here are some advantages and disadvantages of 3D scanning for aerospace.

Pros· Fast and thorough evaluations · Accurate measurements · Non-contact, non-destructive · Cost-effective in long-run |

Cons· High Initial cost · Line of sight is critical for any measurement · Expertise required to perform the scanning |

These points about 3D scanning for aerospace can be expanded upon into various topics. Maintenance, repair, and overhaul, MRO, include the need to be constantly servicing airplanes while the manufacturing sector can also use 3D scanning for aerospace production.

3D Scanning for Aerospace- Solutions for Aerospace Industry

The design, production, assembly, and MRO processes in the aviation sector all demand very precise parts and components. 3D laser scanning produces results at such high precision that every particular detail, is included in the production or data verification process.

Aviation Design

The current emphasis in aviation is moving away from technologically advanced goods with superior performance, towards more competitive, cost-effective products. Designing lighter weight aircraft also helps in lowering emissions.

More aviation experts are developing new models based on the original ones rather than beginning from scratch in response to the changing demands. Retrofitting an older airplane to newer, modernized components allows for the recycling of technology. 3D laser scanning digitizes retro components quickly into the computer, in order to create retrofitted designs.

Another key practice of 3D scanning for aerospace project is computational fluid dynamics, or CFD. The structure of every component of an airplane is scanned using 3D scanning technology to provide 3D data. Then, using specialized software, the data is used to produce CAD models that provide the foundation for CFD analysis. With the creation of proper 3D models, a process called reverse engineering, CFD simulations can be ran to identify the airplane’s weaknesses in aerodynamics.

Maintenance, Repair, and Overhaul – MRO

In the aviation sector, maintenance, repair, and overhaul, MRO, are essential. As long as the inspection precision is not compromised, the shorter the period of time an in-service flight is grounded for review and inspection, the less revenue loss airlines may experience.

Due to the significant amount of money lost during MRO, an hour of downtime for a fleet of airplanes equals to significant financial losses.

The 3D scanning solution for MRO aviation requirements is the ability to verify data instantly from a physical component. Scan technicians can 3D scan an airplane on-site while also comparing to original CAD models. Data verification is visualized by color ways, letting the technician know instantly where problems could arise. MRO results from 3D scanning for aerospace dramatically excels in precision, effectiveness, and mobility.

Building and Assembly

Metrology is highly demanded in the aircraft building sector, particularly when it comes to ship components or the entire structure. When quick and simple measurements are needed, a 3D laser scanning equipment may be used with minimal labour. The handling and operation, which are also relatively simple, are another benefit.

Types of Scanners in 3D Scanning for Aerospace

When 3D scanning for aerospace projects, the type of scanner used must be taken into account. Technically, all models and brands provide 3D scan data that corresponds to the shape of a physical object, but the level of detail varies significantly.

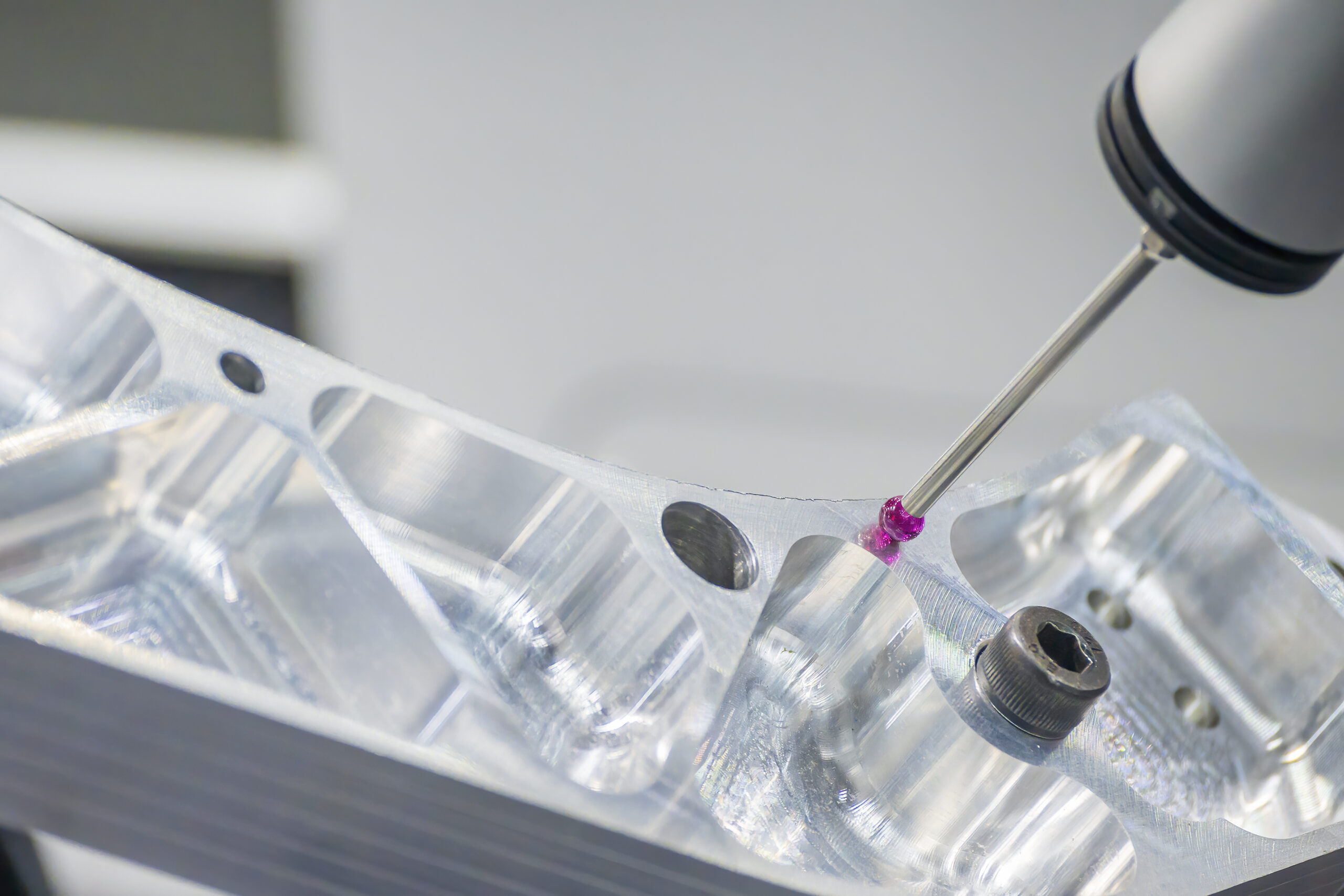

Most aviation projects will require extremely tight tolerances, companies will want to utilize a blue light laser scanner. Delivering results close to 0.02mm, these type of 3D laser scanners are insanely precise and able to detect even the smallest of deviation.

If the wrong scanner is used, the data returned may not be able to deliver high enough results as it lacks the precision required for the 3D scanning for aerospace project objectives.

Blue Light Laser Scanner

The highest adaptability and precision for the bulk of aircraft applications are provided by 3D scanning with a blue light laser scanner. Most of these types of scanners are now portable and hand held. In order to deliver that type of mobility, position

targets are set on or near the object being scanned during this sort of laser scanning. By way of laser triangulation, the laser passes over these targets to make a mesh in between, visualizing what the scanner is seeing.

targets are set on or near the object being scanned during this sort of laser scanning. By way of laser triangulation, the laser passes over these targets to make a mesh in between, visualizing what the scanner is seeing.

Without being constrained by an arm or permanent tripod, the targets function as coordinated locations that let the scanner travel around the item in any direction. More significantly, it does not restrict the subject’s physical capabilities while being scanned. These type of scanners are the most precise, delivering results up to 0.02mm.

Time of Flight Laser Scanners

The laser light used by time of flight scanners is emitted from the scanner’s location. An inbuilt range-finder measures a surface’s distance by measuring the round-trip time of the lasers. These scanners’ accuracy is based on how accurately they can estimate time because of this time measurement. The output is often in the form of a “point cloud,” which is composed of millions of points that have been measured by scanning.

Due to timing the rapid speed of light across such a vast area, their main drawback is a lack of high precision. Although these tolerances are suitable for measurements at a large scale, they are insufficient for the accuracy required for parts made for an airplane.

Structured Light Scanners

Structured light scanners project a distinct pattern of light onto a target using a dependable light source. Internal cameras that are slightly angled away from the light source record the pattern’s form and gauge the separation between each view point on the item.

Since a structured light scanner can scan several locations simultaneously and create data as a triangulated mesh model, structured light 3D scanners have an advantage in data collecting speed and precision. These polygon mesh models have the benefit of being exportable to CAD programs, which use the mesh as a base to create editable, parametric surface models. Final manufacturing efforts are based on these CAD models.

3D Scanning for Aerospace – The Bottom Line

In the aerospace sector, 3D laser scanning is frequently employed to deliver ultra precise and reliable data. From speeding up maintenance results, quality control, and cataloging legacy components, 3D scanning can produce data faster and more exact than previous methods.