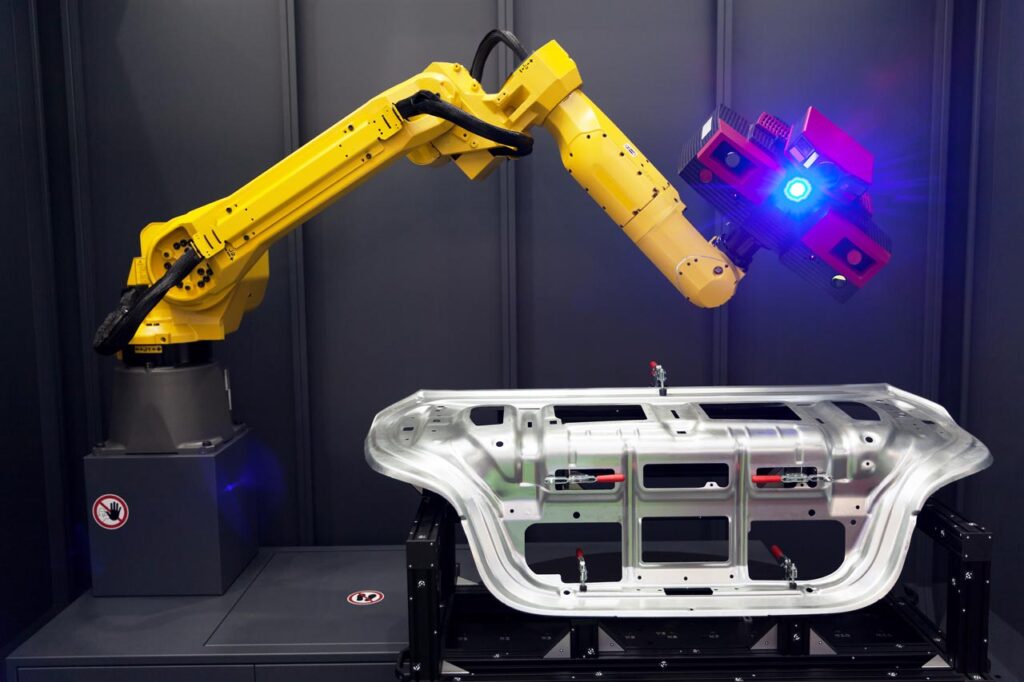

The rapid advancement of 3D scanning technology has allowed for the vast improvement of countless applications across multiple industries. Workflows are now more flexible, as well as more time and cost-efficient than ever before, thanks to 3D mobile laser scanning. It’s no surprise that more companies are incorporating cutting-edge laser triangulation technology to scan objects.

Are you looking for professional 3D mobile laser scanning to help speed up the workflow of your project? This article will explain how industrial 3D laser scanning and structured light work.

Additive Manufacturing (AM)

Additive manufacturing uses computer-aided design (CAD) or 3D object scanners to create medium-sized objects with precise geometric shapes. There are several distinct processes involved with additive manufacturing, each with its own set of standards, which include:

Material Extrusion

Spooled polymers are extruded or drawn through a heated nozzle mounted on a movable arm in this scanning process. As the nozzle moves in automatic scan mode, melted material is built up layer by layer.

Powder Bed Fusion

Powder bed fusion techniques include direct metal laser melting (DMLM), direct metal laser sintering (DMLS), electron beam melting (EBM), selective laser sintering (SLS), and selective heat sintering (SHS).

Sheet Lamination

Sheet lamination technology is divided into two categories such as laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM).

LOM, which employs alternate layers of paper and adhesive, is well suited to producing items with visual or aesthetic appeal. UAM joins thin metal sheets using ultrasonic welding that can be used with a variety of metals.

3D Handheld Laser Scanning at Tangent Solutions

Tangent Solutions leads the industry in high-quality, low-cost 3D scanner services. We use high-precision laser scanners to collect millions of data points, and our experienced engineers can reverse engineer that data and provide you with a high-quality CAD file.

We’ve been assisting customers for more than a decade, and we can’t wait to help you with your next 3D scan project.

Average Cost of 3D Laser Scanning Services

Depending on the size and complexity of the object to be scanned, 3D scanning services might cost anywhere from $100 to $1,000 or more.

3D scanners, on the other hand, are available in a wide range of pricing points, with overall costs varying substantially depending on the model.

More powerful 3D scanners can cost anything from a few hundred dollars to about $50,000.

Do I Need 3D Handheld Laser Scanning?

Structured light scanning is essential at both the beginning and end of 3D fabrication workflows. If you’re thinking about purchasing a 3D scanner for precise measurement, make sure to consider the following:

Volume and Coverage

The amount of space that a 3D scanner can capture varies greatly between 3D scanners. Find 3D scanners that meet your scan dimension size and resolution requirements while not costing too much, as cost typically rises with scan volume.

Resolution

While accuracy is the degree of the absolute correctness of a device, the resolution is the shortest possible distance between any two given points and is usually expressed in millimeters or microns.

Speed

Because time is money, it is critical to consider the scan speed of a 3D scanner and its scanning modes. A faster 3D scanner allows users to scan larger objects quickly, reducing costs and increasing productivity. This is especially important for large, expensive projects with short deadlines.

Choose Tangent Solutions for Your 3D Scanning Needs

A 3D scanner is essential at both the beginning and end of 3D fabrication workflows. Engineers use 3D scanners for scanning objects to begin building digital models faster and more efficiently, whether by incorporating existing designs through reverse engineering or digitizing clay designs.

To learn more about how our intelligent visual inspection equipment can help you with your next project, fill out our online form or contact us at 949-345-0611 at Tangent Solutions today!