3D laser scanning has brought on the ease of manufacturing and data verification for many industries. Can 3D Scanning for guns be used as widely?

3D laser scanning has brought on the ease of manufacturing and data verification for many industries. Can 3D Scanning for guns be used as widely?

The gun industry would also benefit from the precision of 3D scanning services. However, to consider 3D scanning for firearms requires the education of both the design company and client of federal regulations.

In this article, we will delve into the intriguing realm of 3D scanning, exploring its applications, legal aspects, and the benefits it brings to the realm of firearm design and manufacturing.

Understanding 3D Scanning for Guns and Firearms

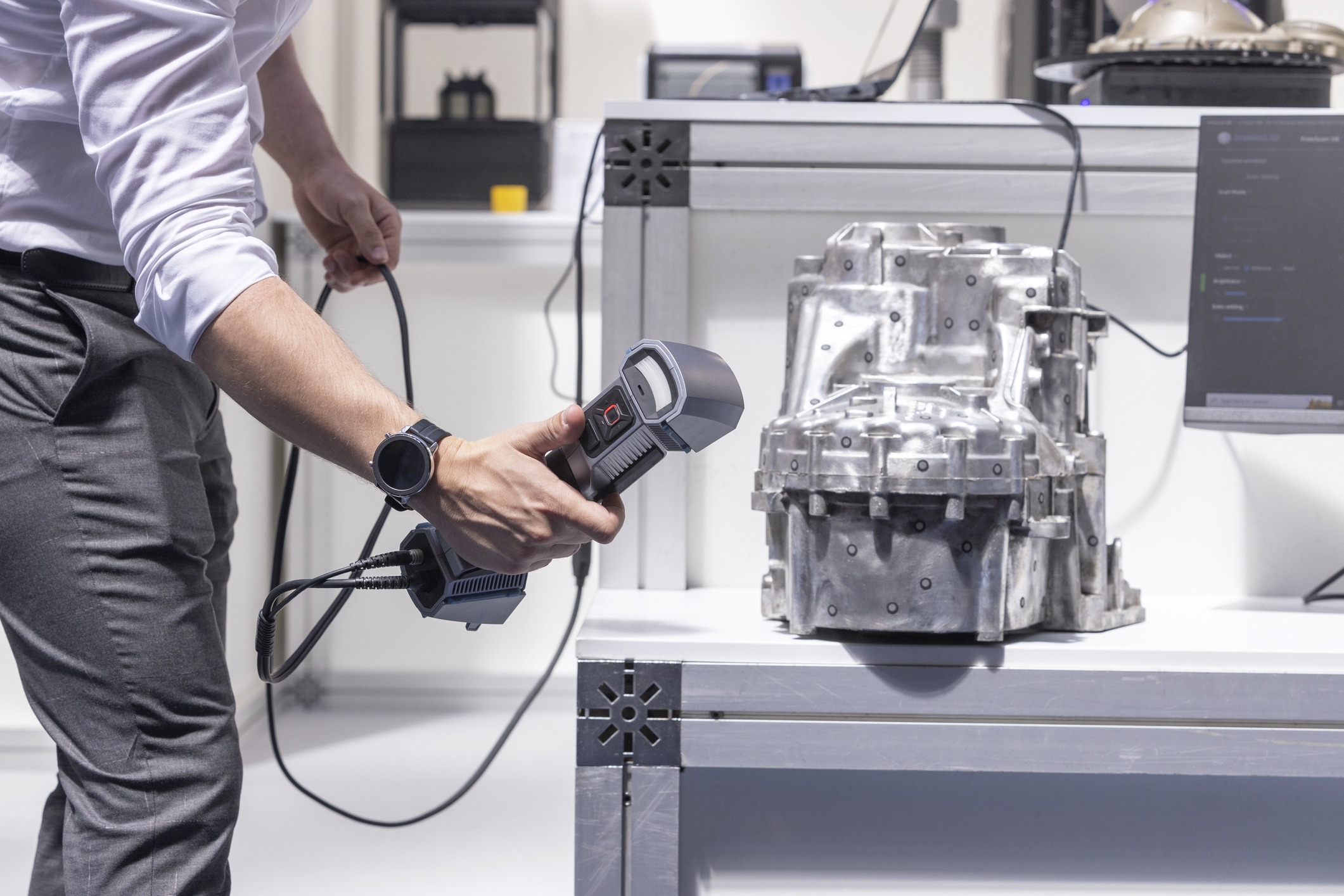

3D scanning is a revolutionary technology that allows for the precise digital replication of physical objects.

In the context of guns and firearms, this process involves capturing the intricate details of the weapon using lasers or structured light, creating a highly accurate 3D model.

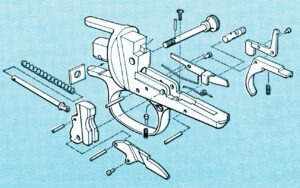

Most firearms are intricate. Deep holes, complex assemblies, and from an engineering perspective, are a design of beauty. That makes them also difficult to replicate and model around.

3D scanning for guns allows for the difficult geometries to be recorded with amazing precision. Data highlighted is down to 2 microns. This results in the opportunity to convert scan data, known as reverse engineering, to CAD files.

Can Every Gun Part Be 3D Scanned?

The short answer to this is yes. However the opportunity to use the scan data afterwards depends upon your licensing.

Although the laws are ever changing, currently the parts of a gun that identify it as a firearm are serialized. Generally, the serial numbers identify the owner and are commonly found on the frame or receiver of the firearm.

It is not legal for an individual or company to take possession of a serialized firearm component without holding a Federal Firearm License, FFL.

What is an FFL?

To comprehend the legality surrounding 3D scanning for firearms, it’s crucial to understand the concept of a Federal Firearm License.

An FFL is a government-issued license that permits individuals or entities to engage in the business of manufacturing, importing, or selling firearms.

This license is a prerequisite for any legal involvement in the firearm industry.

An FFL allows for the proper handling of a firearm component including logging the identity of the registered owner. The check in and out of the gun is recorded so as to trace the interaction.

The gun can then be handled by a business or individual who is not the registered owner. To 3D scan, a company would also be required to hold an active FFL.

What is an FFL – Manufacturer License?

A Federal Firearm License Manufacturer refers to an entity that holds a specific FFL for manufacturing firearms.

This license is granted by the Bureau of Alcohol, Tobacco, Firearms, and Explosives (ATF), ensuring that the manufacturer adheres to stringent regulations and quality standards.

Some vendors are required to hold an FFL – manufacturing license if they are producing serialized components of a firearm. This would not include 3D scanning for guns as nothing is essentially being “made”.

This same scenario is the case for powder coaters, engravers, or anodizing companies. FFL-manufacturing licenses would be held by laser cutters and machine shops however.

What About Parts That Are Not Serialized?

From our understanding, the portion of a firearm that is serialized and issues an FFL requirement, is the frame.

Now some manufacturers may serialize other components like the barrel, bolt carrier, and receiver. This is an expensive and tedious task that in the current landscape, is not required federally.

This opens up 3D scanning for guns to be used for replicating components such as accessories, grips, stocks, barrels, hand guards, and so on.

so on.

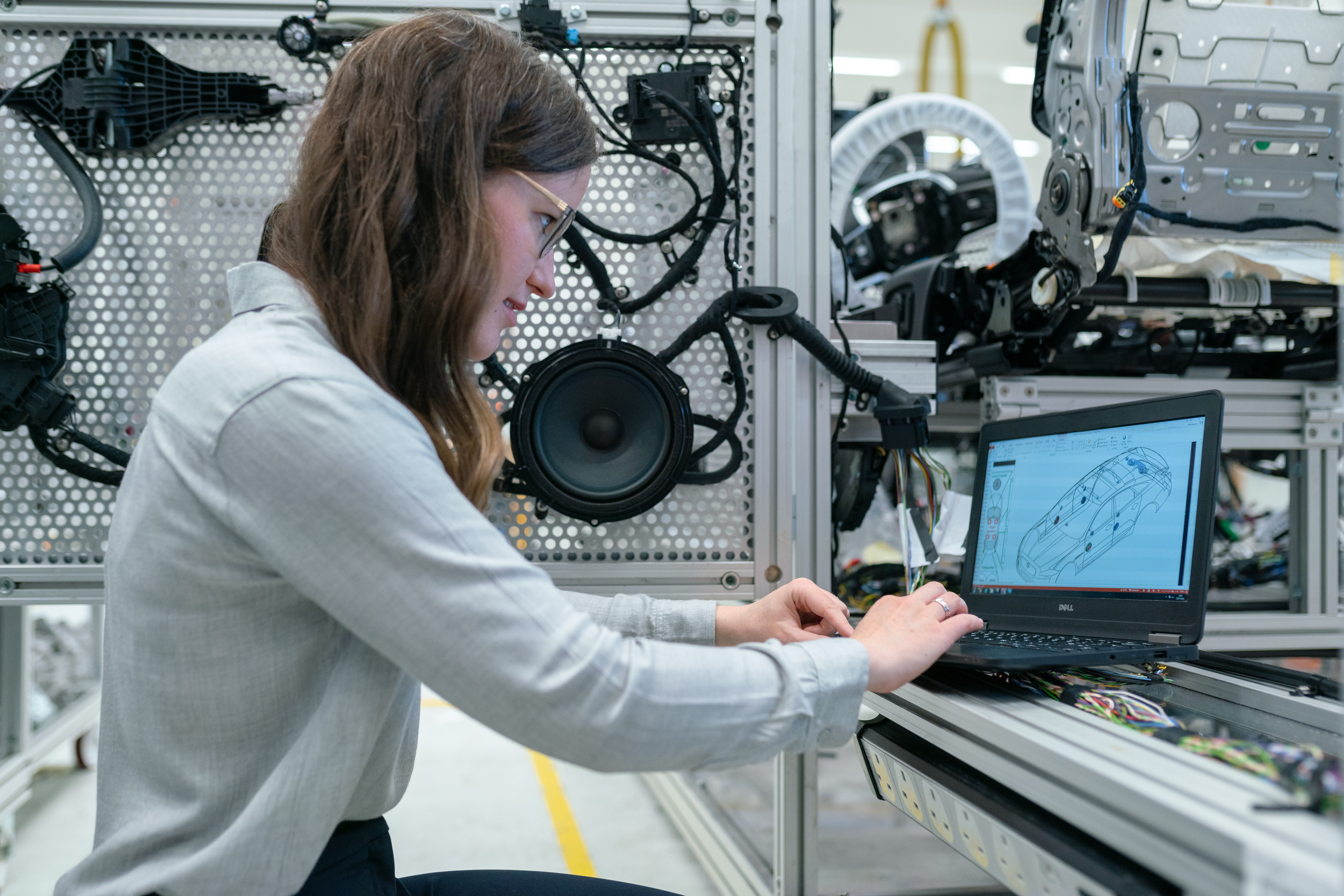

Scanning these components opens up the opportunity to create CAD files of existing models to either reproduce or modify. Although maybe not required, it would be important for any reputable firearm accessory company to hold an FFL.

Scan data will be reverse engineered to CAD just like any other physical object. The data would include precise measurements and detailed interpretation of the firearm.

Owner Presence During 3D Scanning for Guns

When considering 3D scanning for firearms, it’s important to note that the owner of the firearms must be present during the scanning process.

This can be a barrier of entry when choosing a 3D laser scanning service for a firearm project. However, this requirement is in line with legal and ethical considerations, ensuring accountability and proper authorization for the replication of potentially regulated objects.

Currently we are in the process of applying for an FFL license and will announce that approval shortly. This will allow for the proper handling of incoming projects.

Benefits of 3D Scanning for Firearm CAD Files

Being familiar with firearms, a client understands that guns vary in sizes, shapes, materials, and calibers. This offers a plethora of options for customization and aftermarket part opportunities.

Scan data is used to verify the quality of the current product or create CAD files. Files will be delivered in STEP, IGES, or XT with 2D prints to be paired with those files.

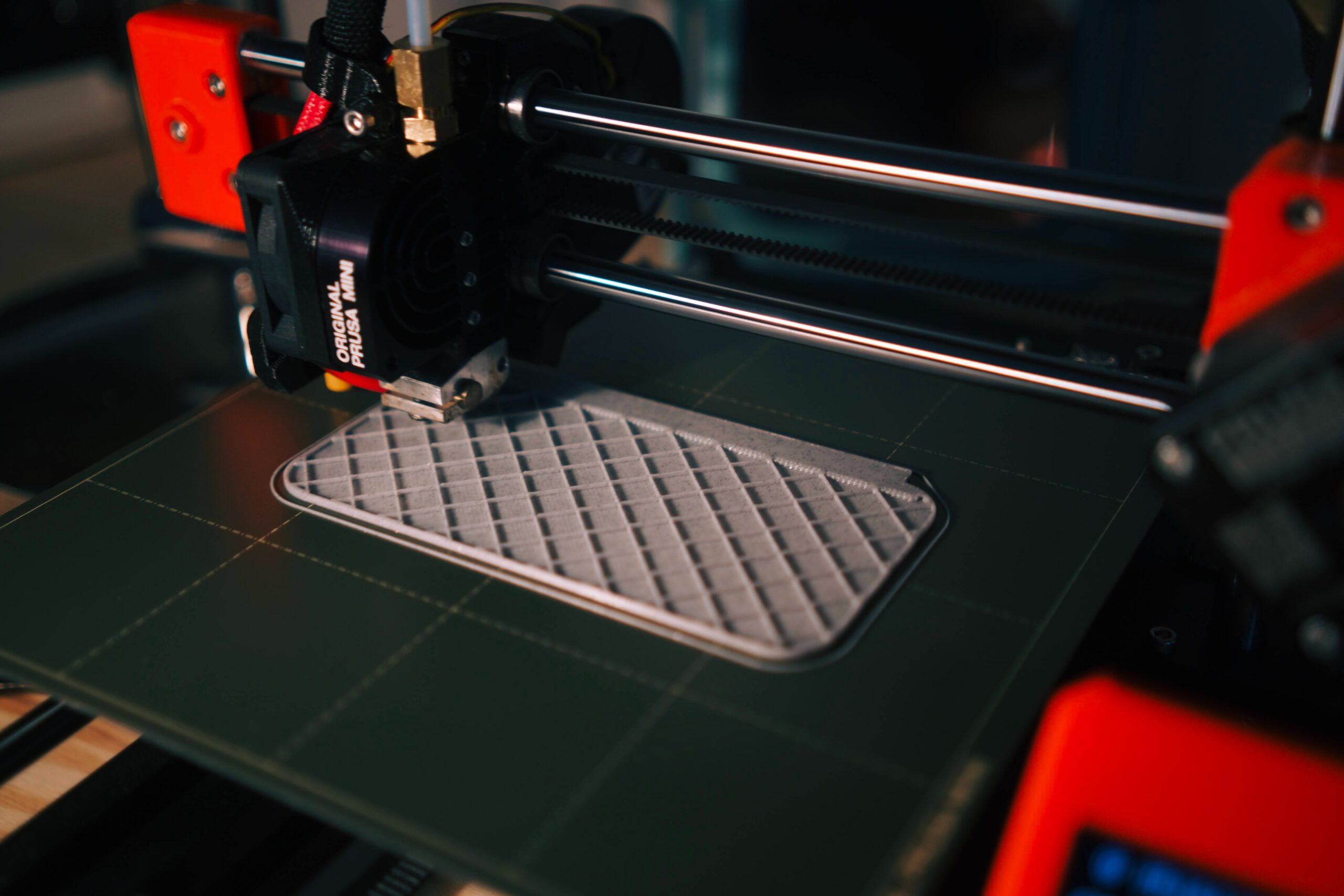

Additionally, 3D laser scanning facilitates the rapid prototyping of firearm components, allowing manufacturers to test and refine designs more efficiently. This not only accelerates the development cycle but also reduces costs associated with traditional prototyping methods.

With that in mind, it is the understanding of the client of the legal requirements in replication. Our intent is to work with reputable firearm companies with a track record of business within the industry.

3D Scanning for Firearms Regulatory Updates

Current laws and updates are based not only by federal regulation but also state. We do require clients to be well versed in their state’s legal requirements of reproduction.

As a company based in California, our understanding is also subjective to staying updated. We stay connected to vendors who can properly use scan data and hold the scope to work with such projects.

Conclusion

As technology continues to reshape the landscape of various industries, 3D scanning emerges as a transformative tool in the realm of guns and firearms.

With a clear understanding of legal frameworks, such as the Federal Firearm License, and the benefits of 3D laser scanning, the firearm industry stands poised for a new era of innovation and precision.

If you have more questions about this topic, please reach out to us.