3D scanning is quickly becoming an essential part of product designing and manufacturing. When used effectively, it can increase production efficiency and improve the quality of your products. However, doing this yourself can take extra time and focus out of your business day — which is why it’s often better to outsource your 3D product scanning services. This way, you can save time and money.

Before hiring another company to take over 3D scanning, we recommend doing some research first. When it comes to 3D scanning services, not all outsourcing firms can deliver excellent results. It will largely depend on their technology, equipment, and expertise.

Here are some tips on what to look for when choosing a scanning service to help you make the most of your resources.

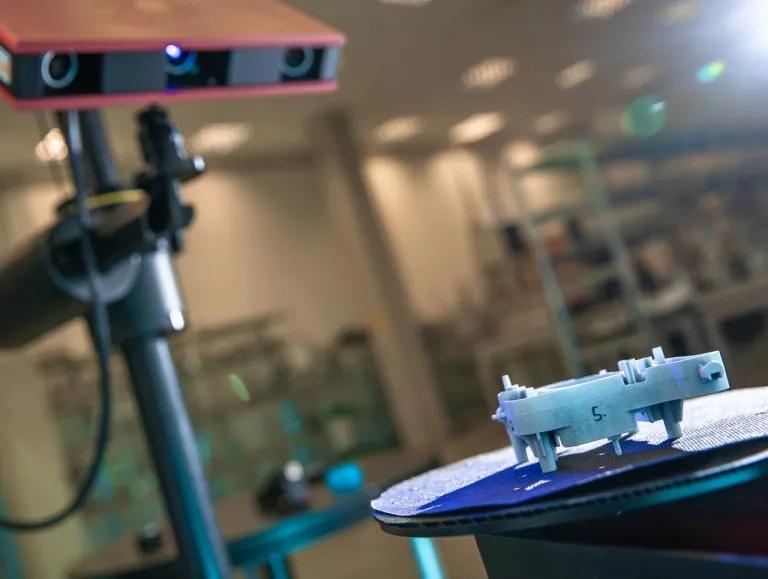

1. High-Quality Equipment

When you’re relying on a company to provide all your scanning services, they must have the best equipment for the job. Before committing to a scanning company, learn more about the equipment they use and how it works.

Not all 3D scanners are equally effective. They have different resolution capabilities, size limits, and other factors. As you ponder different options, consider the size of items you need to be scanned.

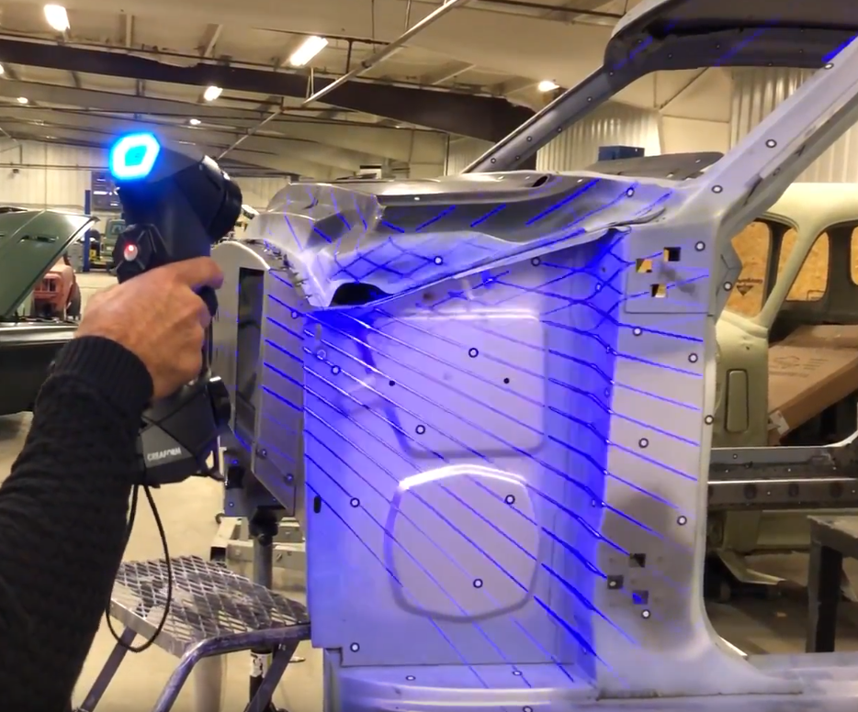

Tangent Solutions is a 3D scanning company that utilizes state-of-the-art scanners for more detailed results. Our handheld laser 3D scanners are high-resolution and can handle objects of any size — from car parts to buildings.

2. Fast Turnaround Rate

When choosing a company to work with, you may want to consider how responsive and reliable they are. A company that responds to messages quickly, for example, is more likely to respond when there’s a problem with a file.

Our team offers scanning services locally, and we can also scan items that are shipped to us. As soon as the items arrive at our headquarters, they are immediately scanned, allowing us to maintain our impressive turnaround rate.

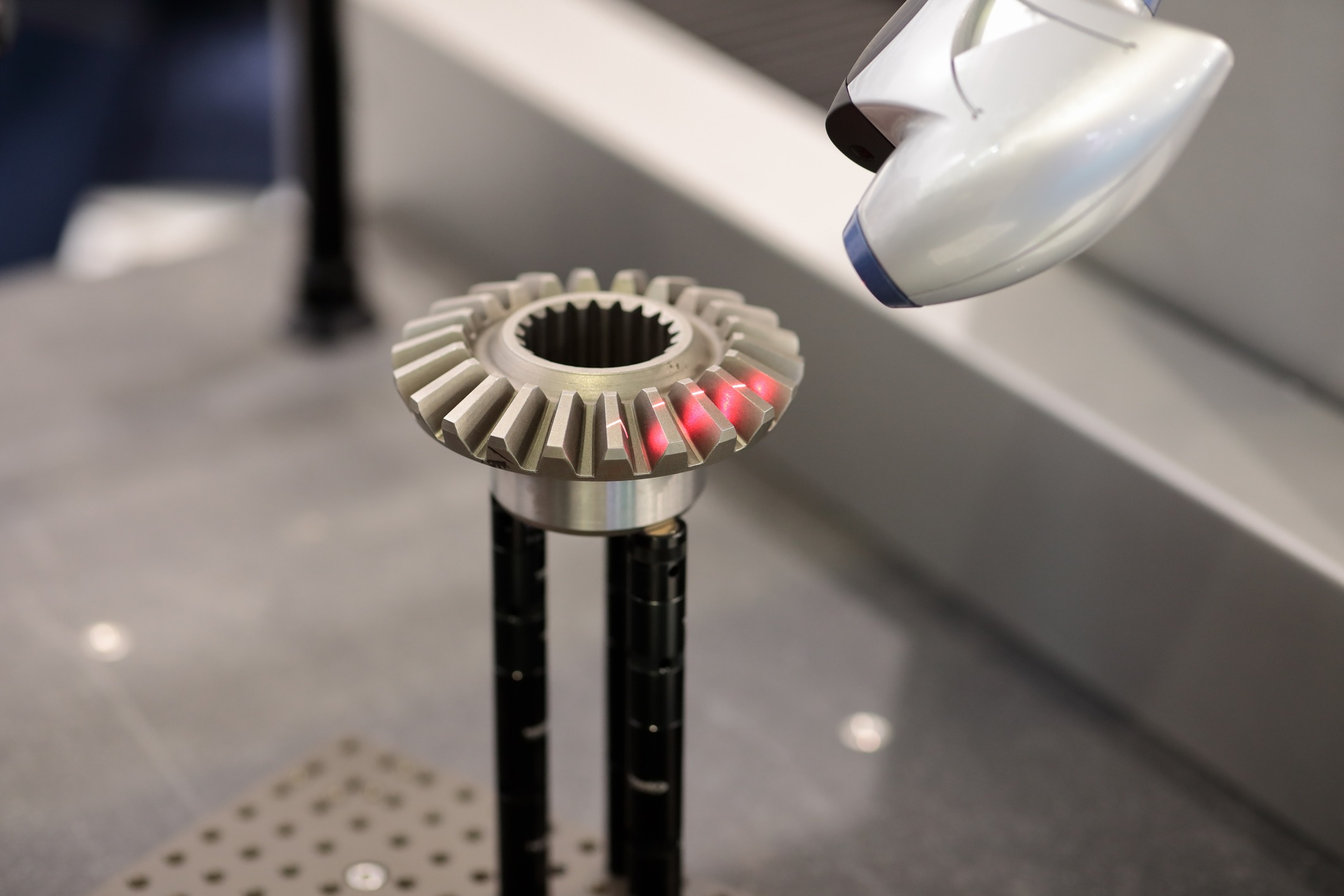

3. Multiple Services Offered

As you consider different product scanning companies, it’s important to find one that reflects your needs. A company that offers more than just product scanning will streamline the time it takes to take an idea from the design stage to the finished product.

Not only does Tangent Solutions scan 3D products, but we also process the resulting files into Computer-Aided Design (CAD) files. Our CAD team can help you modify files, design new products, and even reverse engineer products in a timely manner.

4. Expert Team Members

3D product scanning can help you develop items, reverse engineer them, and more. Your outsourcing company must have experienced and knowledgeable team members. Skilled staff will be able to help you every step of the way and provide suggestions when necessary.

In Tangent Solutions, our technicians handle our laser scanners with confidence, providing highly accurate results each time. We have skilled employees to handle all of your product development needs, including CAD engineers, drafting staff, and more.

5. Consultations

Many companies provide consultations so you can learn more about the details of their scanning services. Consultations allow you to get a quote and see how the company will help you achieve your scanning and product design goals. After meeting with a company, you’ll have a better sense of whether or not they’re a good fit for your business and budget.

Tangent Solutions provides 3D scanning, printing, and CAD designs to help our clients create quality products. Contact us today to learn more about our services!