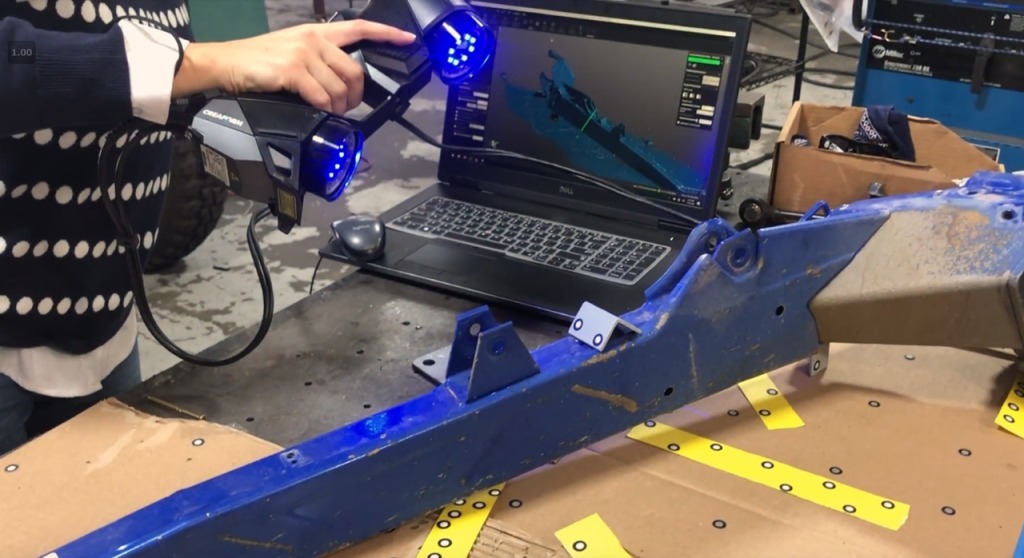

Designing products and bringing them into the world is an exciting endeavor for any company. 3D scanning is a new tool that makes creativity easier than ever. With 3D scanning services provided by Tangent Solutions, data created is versatile enough for use in prototyping, reverse engineering, and much more. Our 3D mobile laser scanning services also highlight that there are no size limitations.

3D laser scanning is still a relatively new technology and it’s constantly undergoing innovations that make it easier to use. It’s important to stay informed of the latest updates to the field and how best to use the technology.

What Is 3D Laser Scanning?

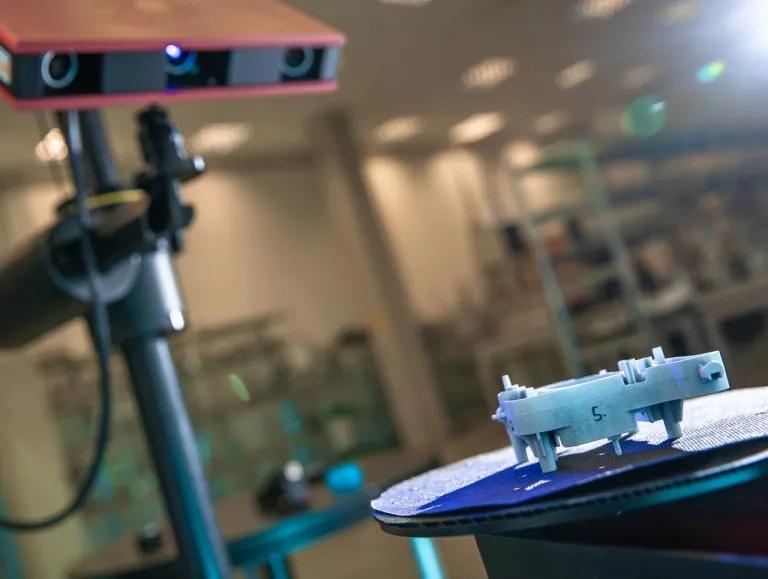

3D laser scanning uses a series of lasers to create a triangulation map of data points. By aiming the laser scanner at an object and measuring its reflection back, data points created develop into a mesh in order to illustrate shape and measurements of the object being scanned.

Laser scanning has the benefit of being convenient, reliable, and accurate. The most advanced laser scanners available are precise in measurement to a thousandth of a millimeter. In comparison to camera technology, it can be used on surfaces that present a challenge, such as dark or reflective projects. Laser scanners are less sensitive when it comes to lighting or weather conditions.

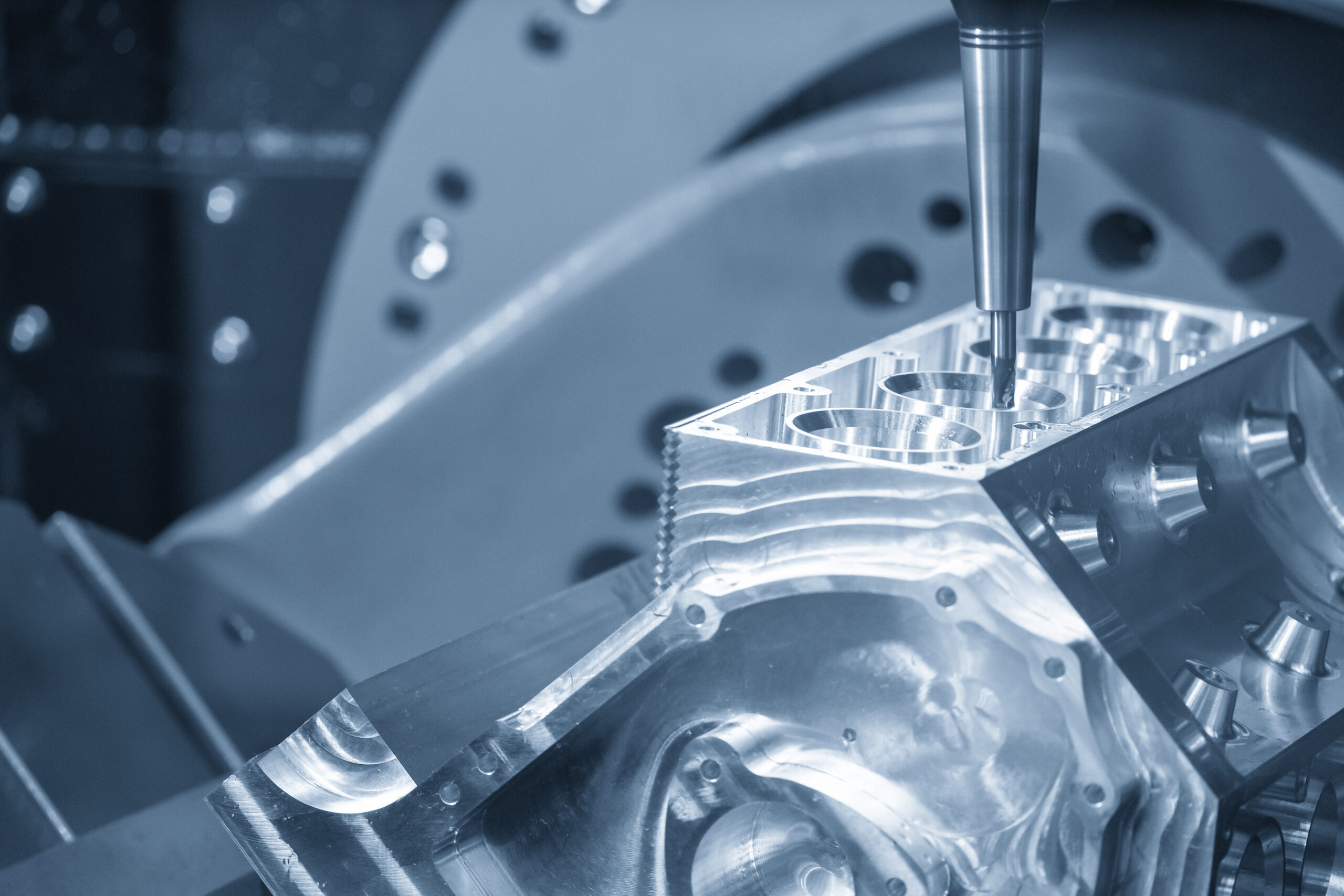

After a 3D scan, you’ll be left with the raw scan data. Our scan technicians will clean up the erroneous data, orientate the model, and make it easier for you to import. We can also reverse engineer it into a 3D CAD model, using the scan data as a guideline.

What Are the Best Practices in Laser Scanning?

Just like any engineering technique, 3D laser scanning has some best practices that will help you stay on track for a successful project. We recommend these practices for maximum efficiency and the best result:

Have a Scan Purpose in Mind

Before performing the 3D laser scanning process, consider the purpose of the scan and the ultimate goal of your project. That means deciding at what point of your project the scans will be used, so you can focus on the right elements. Are you looking to understand weak points in a product? Are you looking to gather data for modifications to the component?

By communicating with our team directly about what your goals are, can help deliver the best results and collection of data. We tailor each scanning project based on these goals which eliminates billing of extra time, gathering data that is not needed.

Determine the Scope of Your Project

Scope can help guide what is scanned and how you use the data. Our team can work with you to figure out how best to use this technology and where scanning fits into your overall plan. We have experience helping our clients pinpoint potential uses for 3D laser scanning and getting the full scope of capabilities of scan data.

One of the benefits of our 3D scanning services is the ability to charge by the hour versus by the project. This means you can include multiple components to be scanned at once, even if you are initially ready for the scan data. Files can be created and save for future projects and it is more cost effective to scan all components at the same scan time.

Collect as Much Scan Data as Possible

When you are working on a project, it’s always better to have too much data than too little. We recommend requesting a higher resolution than you think you’ll need, scanning extra components, and getting as much detail as possible during your scheduled 3D laser scanning service.

It’s more convenient to collect excessive data than it is to dive into a project and find out you’re missing information. This is even more essential during mobile laser scanning service as it is charged by half-day, or full-day rates.

Scan Preparation

Before your 3D laser scanning service, you will need to have all components cleaned. Components should be free of dirt, debris, tape, or any other miscellaneous build up. The 3D laser scanners used in the process are so precise, any erroneous texture will be visible in the scan. This can throw off measurements including thickness or hole sizes due to the debris.

If you have questions about the color or reflectivity of your component, reach out to our technicians and we will be able to advise on the scanning approach. The 3D laser scanning system we utilize is not susceptible to conditions such as light or color. However it can struggle with transparency or extreme reflectivity.

This is due to the nature of the collection of scan data. The lasers that are emitted from the scanner, need a surface to bounce off of, back to it, in order to create the mesh. Transparent material of course, allows the laser to pass through and not collect any information of the component’s shape. Highly reflective materials bounce the lasers away from its original trajectory.

This does not eliminate the possibility to 3D laser scan reflective or transparent components. Our team stocks scan spray that layers on a powder-like substance that eliminates these characteristics. For fragile projects, we also have AESUB 3D Scanning Spray, a revolutionary spray that disappears on its own and does not leave any residue. Paired with these materials, we can 3D laser scan any project.

File Formats and Deliverables

Understanding what type of file formats are needed in your project will also help stay within budget and scope. Our team of design engineers can export in mesh-only files, including STL and OBJ, while also completely reverse engineering data to universal CAD files; STEP, IGES, and XT.

It is essential to understand the files you need. If you are looking to have a project manufactured, you will need a CAD file. This is created in the reverse engineering process and is more time consuming. Are you looking to create data purely for conceptual purposes? Then STL files are what you need.

We have created a sample folder in order to help validate which type of files our clients need in their project. The team is more than happy to discuss your project goals to make sure you receive the correct files.

What’s New in 3D Laser Scanning?

Laser scanning is still new to many companies, but those who adopt the practice overwhelmingly find it to be a worthy use of their time. Looking to the future, laser scanning may have untapped potential.

Some recent improvements have made reverse engineering easier. Increased accuracy means that more industries can turn to 3D laser scanning for production, prototyping, and other purposes. Current industries we have teamed with include consumer products, aerospace, motorsports, aftermarket automotive components, and manufacturing; to name a few.

Capturing complex shapes is easier to accomplish and the 3D laser scanning system we trust in our business, leads to overall better models that are fully functional and efficient.

At Tangent Solutions, our goal is to help companies develop new products, manufacture them smoothly, and even improve existing products. Contact us today to learn more about how laser scanning can benefit your company.